Completely 3D capable parallel kinematics for friction stir welding and milling of large parts

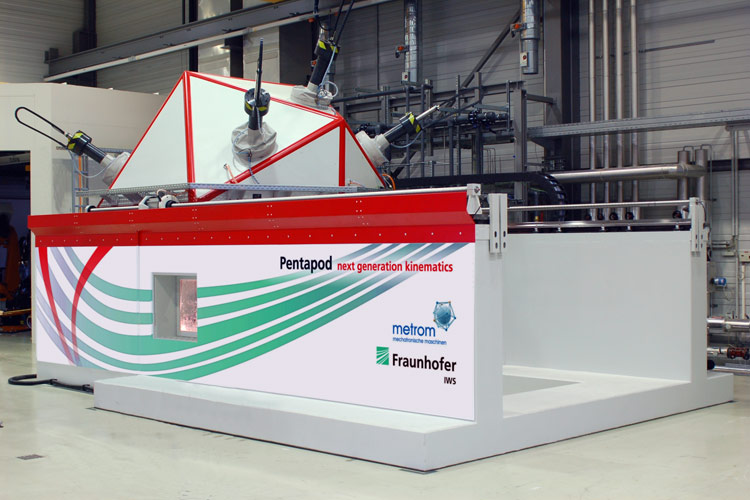

Pentapod parallel kinematic machine tool for 3D friction stir welding and milling

Setup of the parallel kinematic machine for friction stir welding (FSW)

Manufacturer

- Metrom Mechatronic Machines GmbH

Technical data

7 axes portal machine:

- 5 moving axes for 3D motion of main spindle, additional linear movement to extend the workspace

- round table to process from all directions

- standard CNC control

- integrated control system for friction stir welding, possible control algorithms:

- force control

- momentum control

- position control

- max. rotational speed of main spindle: 17,000 rpm

- dimensions (L x W x H): 7.2 x 3.7 x 5.3 m

Workspace

- x-axis 2 m

- y-axis: 6.5 m

- z-axis: 1.5 m

- feed rate: 20 m / min

- max. tilt of main spindle: -100°

- b-axis: rotational axis ∅ 2 m

Applications

- friction stir welding up to 12 kN

- milling

- laser beam welding

- deep rolling

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS