Digitalization has long since found its way into industry and has become one of the most important elements of value creation. It is now taken for granted to design a component on the computer and immediately simulate its behavior in the application.

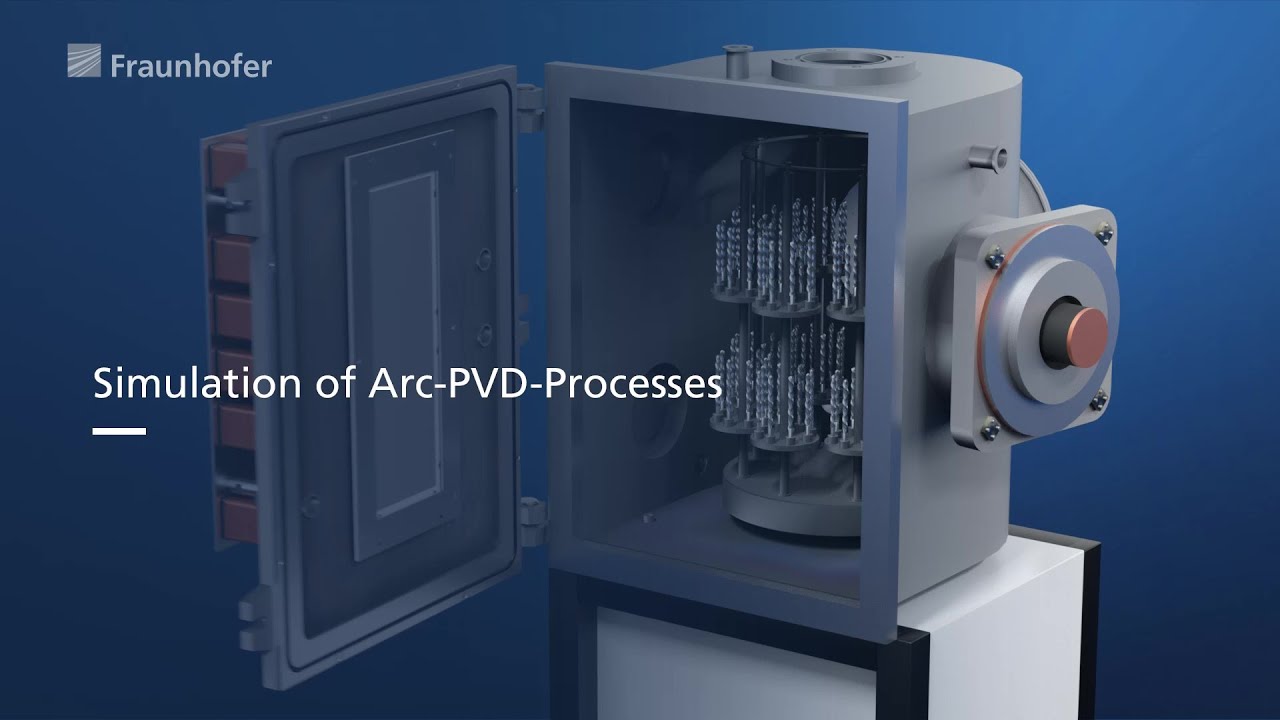

We deal with the simulation of arc coating processes, in particular with the processes on the evaporatior cathodes, in the plasma and on the substrate surface.

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS