Investigations regarding the shielding behavior of carbon nanotube-modified flexible sealing adhesives as well as potting and coating solutions for electromagnetic interference in the spectrum from 104 to 109 Hz (carBONDshield)

Motivation

All electrical systems and devices generate electromagnetic waves and are therefore sources of electromagnetic interference (EMI). An important factor in advancing digitization is wireless communication between a wide varieties of devices. To enable this at the necessary high speed, low latency and error rate for a wide range of devices, new wireless standards such as 5G mobile communications are required. These standards operate at frequencies in the single (cell phones) to double-digit (Industry 4.0) gigahertz range to achieve the requirements. In order to keep interference with sophisticated electronics applications as low as possible despite increasing "electromagnetic pollution", new types of shielding concepts are needed.

In addition, the use of high frequencies can also lead to more frequent interference of individual components within the electronic components. Due to the ongoing miniaturization of devices, more and more functions have to be accommodated in a very small space, which is why conventional methods such as encapsulation using metallic shielding plates are reaching their limits, and not just because of their limited shielding performance. At the same time, the requirements with regard to device failures and reliability are also increasing, for example in mobile devices, wearables, transport electronics and industrial control systems.

With the continued electronization and digitalization of our lives, these challenges will become even more acute as more and more powerful sources of highly fluctuating electromagnetic interference fields are added. Therefore, technical solutions for the reliable shielding of electromagnetic fields, especially in high-frequency areas, are required.

Technology state of the art

Current solutions include the metallic coating of encapsulated components by means of physical vapor deposition (PVD), spray or inkjet processes. The main cost drivers here are the necessary vacuum technology (PVD) or the handling and storage of the mostly highly filled silver inks. The resulting layers are mostly rigid and brittle, so that their suitability for flexible electronics applications is limited.

Solution approach

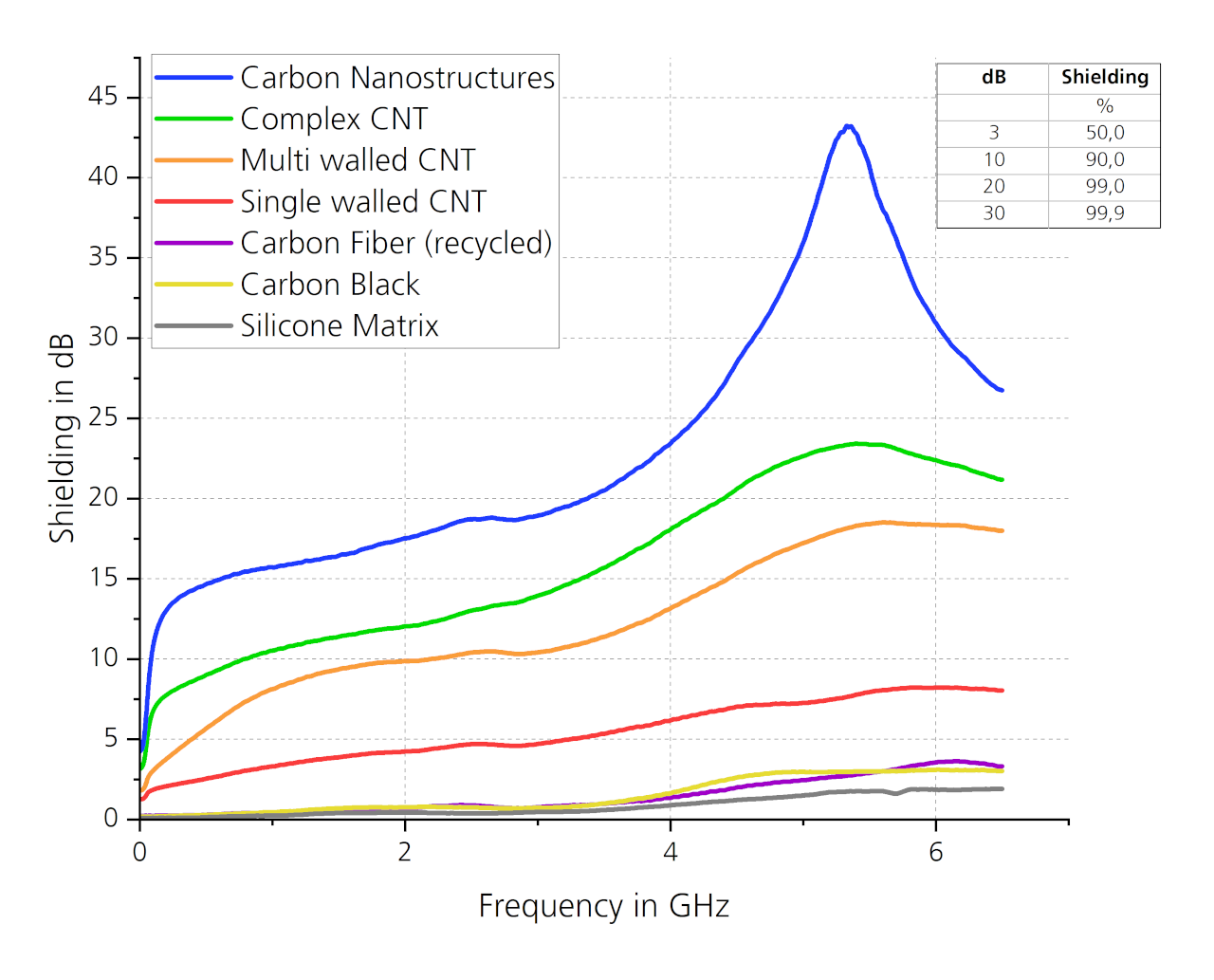

The development of elastic shielding systems based, for example, on polyurethanes or silicones with minimal filler contents shows a high relevance. In the IGF project ESDBond, SKZ and Fraunhofer IWS have already successfully modified flexible electrically conductive adhesive and potting systems to dissipate electrostatic charges. Significant reductions in the electrical volume resistance (up to 13 orders of magnitude) were achieved by adding very small amounts of carbon nanotubes, which also means that the electrically conductive modifications are only associated with moderate price changes in the initial systems.

Building on these findings, shielding applications based on polyurethane and silicone are to be evaluated and optimized in the "carBONDshield" project to improve electromagnetic compatibility (EMC). Adhesive systems for bonding and sealing as well as potting and coating systems for encapsulating electronic components are being considered.

In addition to the investigation of homogeneous CNT networks of the same type, the work will focus in particular on segregated filler networks comprising more than one type of filler. This includes, for example, the use of other fillers such as silver nanowires (AgNWs) or soft magnetic additive mixtures in addition to various carbon allotropes. In particular, concepts will be developed to build multilayer structures with improved shielding using these materials. This should lead to higher throughputs and lower implementation costs for more efficient EMI shielding solutions.

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS