First insights in the Annual Report 2020/2021

Functionalization of suspension-sprayed oxide film surfaces

In recent years, extensive development work has revealed the potential of thermal spraying with fine powder suspensions with particle sizes in the sub-micrometer and nanometer range. Suspension spraying enables the fabrication of tailored coatings in which layer thicknesses, morphology and properties can be varied over an extremely extensive application range.

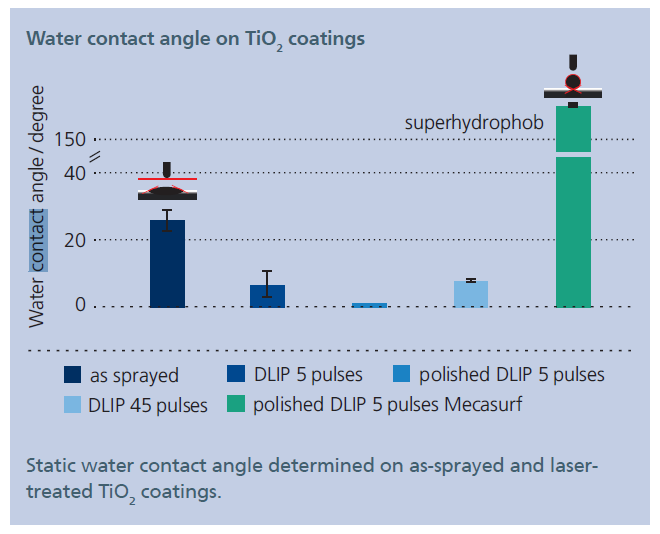

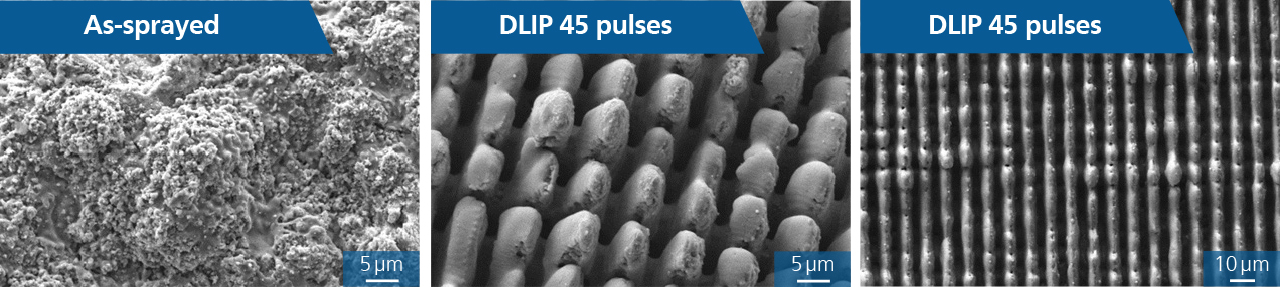

Surface modifications extend the functionality of suspension-sprayed coatings. Researchers at the Fraunhofer IWS applied direct laser interference patterning (DLIP), a technology developed in-house, for the first time to functionalize the topography of suspension-sprayed titanium oxide (TiO2) coatings. DLIP thereby creates periodic micrometer-sized structures on the coating surfaces. The photocatalytic activity of TiO2 layers can be significantly improved if they have been previously laser-structured. In experiments, the scientists observed a color change from light gray to velvet black when they laser-treated the coating surfaces. Laura Toma explains: “This process opens up the possibility to develop absorption or anti-reflective coatings. In addition, suitable laser patterning allows the design of superhydrophilic or superhydrophobic suspension-sprayed TiO2 coatings.”

The researchers applied DLIP to structure metallic bond coats to develop a new generation of suspension-sprayed thermal barrier coatings made of yttria-stabilized zirconia (YSZ). “The combination of suspension spraying with direct laser interference patterning thus opens up new paths for the development of promising functional coatings for applications in self-cleaning, antibacterial and antiviral, super-hydrophobic surfaces, anti-icing, optical coatings, nature-inspired biomimetic and smart coatings”, gives Toma as an insight into the future.

News: Toma elected to TSS board of directors

Dr. Filofteia-Laura Toma has been elected to the ASM Thermal Spray Society (TSS) Board of Directors. The scientist conducts research on thermal spraying at Fraunhofer IWS. She has been working in this field for 20 years and is already a member of various national and international committees. TSS was founded in 1994 and has grown to about 1,500 members around the globe representing more than 500 companies, research institutes and universities. The Society's vision is to be the world's leading source of thermal spray information.

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS