Fraunhofer Institutes Establish New Branch for Aviation Research in Cottbus / 2023

Thrust for Hybrid Electric Flying

Several Fraunhofer Institutes and the Brandenburg Technical University Cottbus-Senftenberg, under the leadership of Rolls-Royce Germany and other partners such as the research institution ACCESS, are collaborating on the future of hybrid electric flying. Supported by the state of Brandenburg and the Federal Ministry for Economic Affairs and Climate Protection, the partners are researching an entirely new propulsion system for medium-range aircraft with up to 35 passengers.

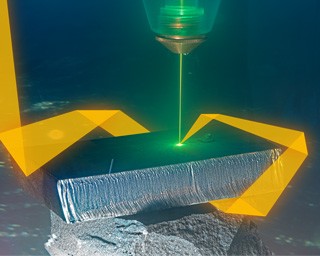

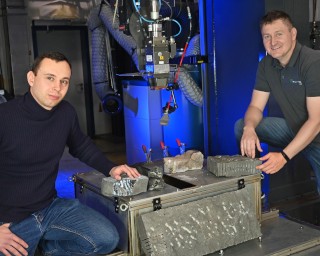

more info Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS