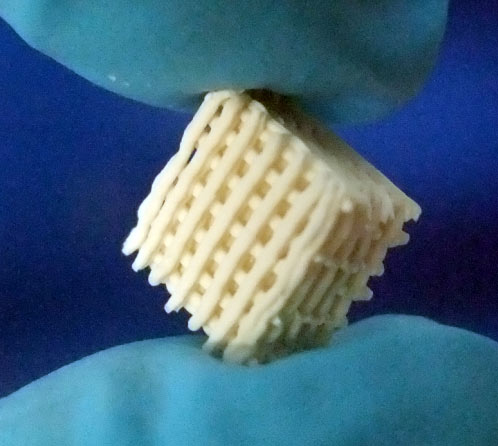

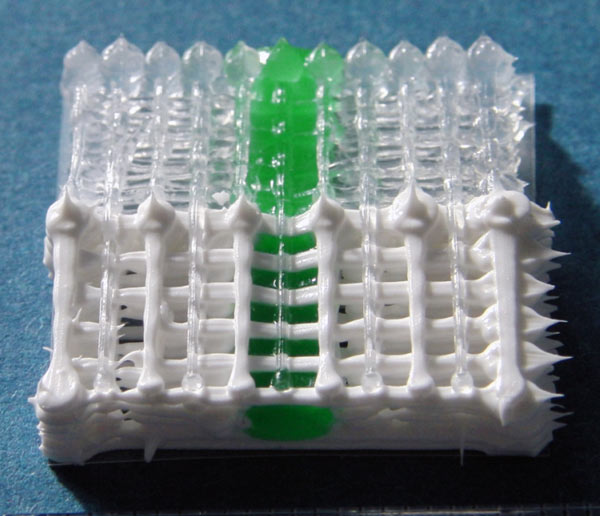

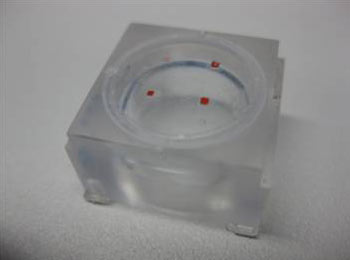

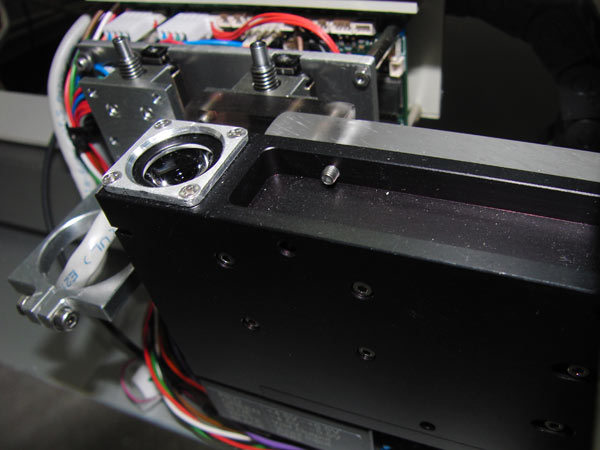

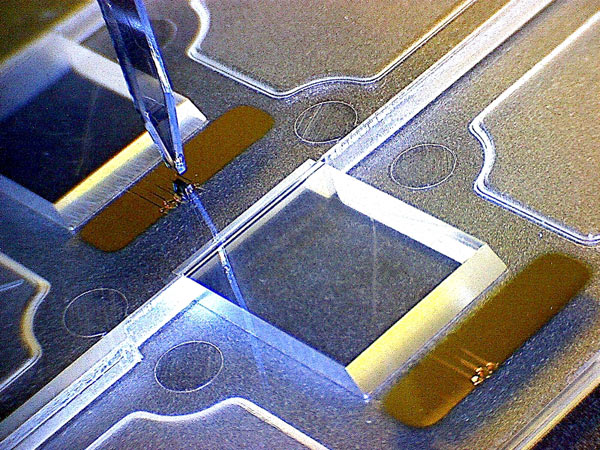

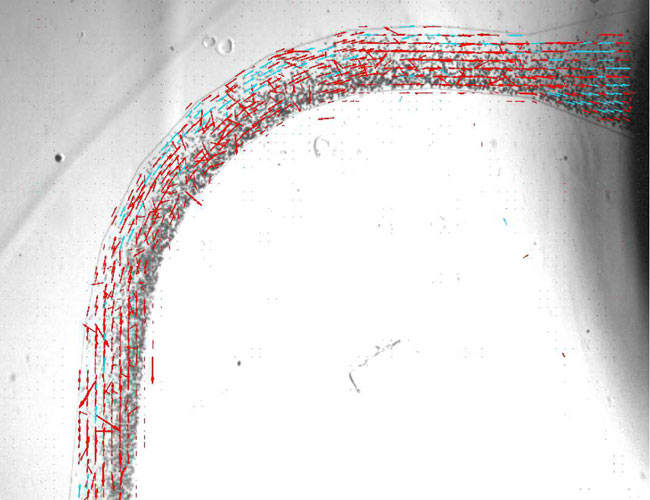

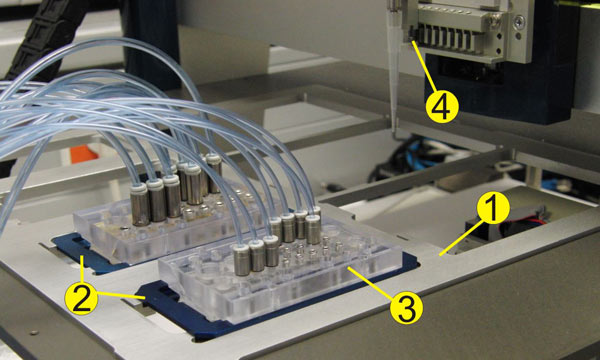

Lab-on-a-Chip, the miniaturized laboratory on a chip, is a complex system for the simultaneous query of several parameters of one specimen. The SPR measuring device, developed at the Fraunhofer IOF, presents the basis for the Lab-on- the- Chip development. It consists of a reading system and the corresponding SPR chips. In order to measure smallest amounts with the best possible signal-noise ratio, different approaches, such as dielectrophoresis, magnetrophoresis and hydraulic focusing were optimized per simulation. The realization of the corresponding micro-fluidic specimen handling system was done by a Rapid-Prototyping procedure.

Producer

- Fraunhofer IWS / Fraunhofer IOF

Principle

- surface plasmon resonance

- signal increase by using different physical effects during the specimen handling

Technical data

- specimen volume: < 60 µL

- measurement period: depending on the application from 2 min to up to 2h

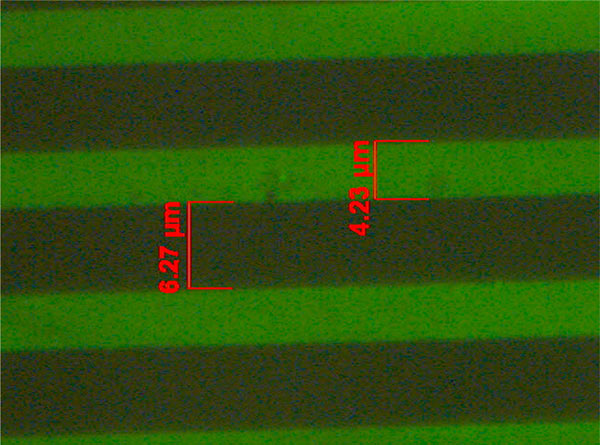

- analytes numbers are dependent on the immobilization method (e.g. 17 measuring areas of 200 µm width during the functionalization by inverse Micro-Contact-Printing)

Applications

- detection of genetic mutations (DNA detection)

- detection of phytopathogen RNA viruses (RNA detection)

- immunological in-vitro test of substances with artificial humane lymph nodes (antibody detection)

- quick point-of-care diagnostics of bacterial infections (antibody detection)

- detection of various substances in water

- substance testing – detection of particular markers in cell culture supernatants

- substance testing – detection of interaction between receptor and ligant

Advantages

- disposables – polymer chips are suitable for mass production

- parallelism – up to 180 spots enable various applications without need of testing

- non-imaging SPR – angle-resolved measurement offers simple error detection and high measuring reliability

- open system – combination of SPR measurements and various microfluidic systems, depending on requirement

- robust – no moving mechanical parts

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS