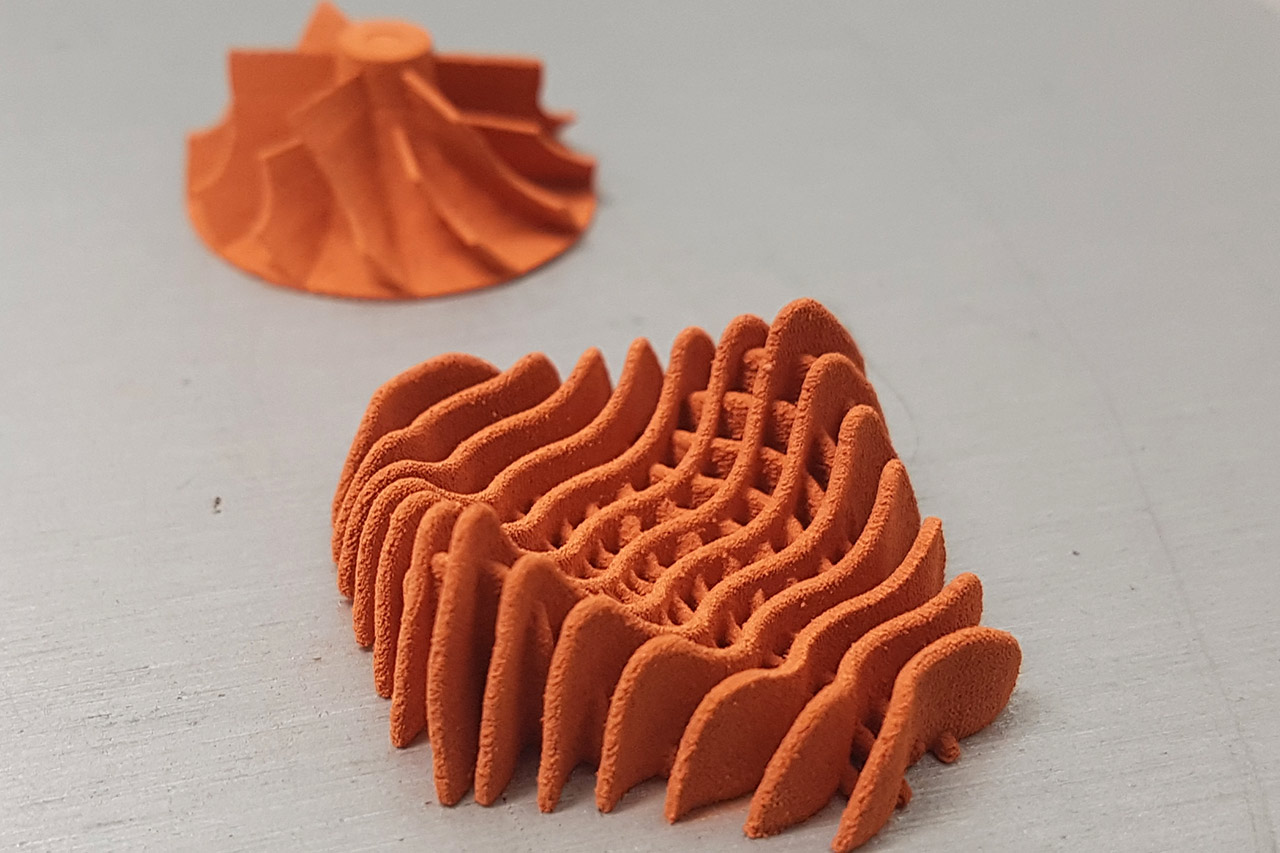

Additive Manufacturing as a young technology offers a lot of potential for both industry and science. Along the complex process chain, numerous factors influence the quality and cost of the components: from design through material and system properties to post-processing. Aspects of sustainability also play an increasingly important role.

The working group deals with the acquisition of data along the additive process chain and uses it for process evaluation and improvement as well as for quality assurance. A strong focus is on the use of software, especially for process simulation. Examples are thermomechanical simulation to determine stresses, temperatures and distortion in LPBF and DED processes or distortion and shrinkage compensation in sintering of binder jetting components.

Our range of services includes:

- Evaluation and optimization of components and assemblies for additive manufacturing

- Software-supported layout and design of components, simulation of processes

- Development and use of system technology for AM process monitoring

- Optimization of AM process chains under the aspects of feasability, costs, resilience, sustainability and integration into higher-level processes

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS