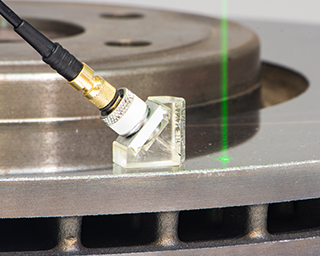

No reliable products without quality inspection and product labeling. That is why we are researching in this area to develop protective solutions against the increasing global trend of product piracy. Thus, material characterization and testing is one of Fraunhofer IWS’ core competencies. Our high-precision testing methods contribute to quality assurance in the development of innovative processes and validation of new materials. Load component testing, for example, provides information about coating adhesion, weld seam quality or compressive loading. With our expertise in materials testing and laser research, we support automotive manufacturing with laser acoustic as well as optical inspection and testing methods.

Product labeling has also gained tremendous importance in a globalized world. In order to safeguard future technologies, we contribute our many years of experience in the research, development and application of laser-based methods such as laser structuring, laser engraving or laser labeling. Regardless of whether they are visible to the naked eye or not, our solutions generate product protection features for unique identification to minimize the risk of copyright infringement.

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS