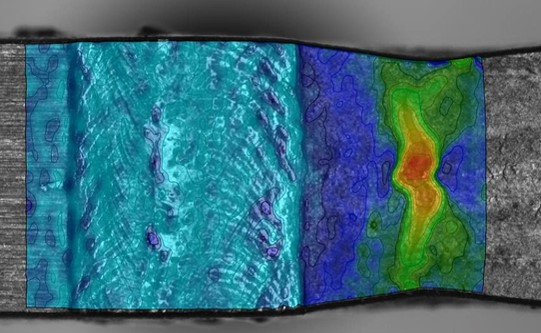

The verification of local deformation states is a crucial prerequisite for a structure-optimized component design. At Fraunhofer IWS, state-of-the-art camera-based systems are used to quantify stress distributions based on local deformations in complex structures. These optical measurement systems allow, among other things, an evaluation in the form of force or stress-strain curves for different areas in the captured image section. This makes it possible, for example, to explicitly record the deformation behaviour of the weld metal in a weld sample. This provides a validation basis for simulations of the deformation and failure behaviour of complex or graded areas in the micro to millimetre range.

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS