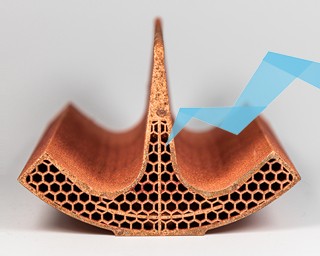

World first: Fraunhofer IWS for the very first time prints quadrupole components for linear accelerators / 2021

Additively manufactured copper components for linear accelerators

A new generation of particle accelerators aims at taking cancer therapy, drug detection and material analysis to a higher level: These linear accelerators are so compact that they are becoming affordable even for smaller hospitals, airports and laboratories. To support this development, the Fraunhofer Institute for Material and Beam Technology IWS, together with the European Organization for Nuclear Research (CERN) in Switzerland, Latvia's Riga Technology University (RTU) and Politecnico di Milano (PoliMi), is focusing on laser-based 3D printing: As part of the I.FAST project, aimed at enhancing innovation in accelerator and co-funded by the European Commission’s Horizon 2020 program, researchers succeeded for the very first time worldwide to additively manufacture essential quadrupole components for linear accelerators from pure copper.

more info Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS