Vive la steel construction revolution – faster, better, cheaper steel welding

Laser welding paves the way for steel construction revolution

Many people associate steel construction technology with manual welding and glaring arcs. In order to manufacture large-scale, highly stressed steel structures such as overhead cranes or wind turbine towers in line with high quality standards, exten¬sive technical expertise and efficient processes are required. High-energy, modern joining processes such as laser beam welding will revolutionize steel construction in the coming years. A research project conducted over the past 2.5 years on low-distortion and low-energy laser beam welding for thick-walled steel structures follows precisely this goal.

Vive la steel construction revolution – faster, better, cheaper steel welding

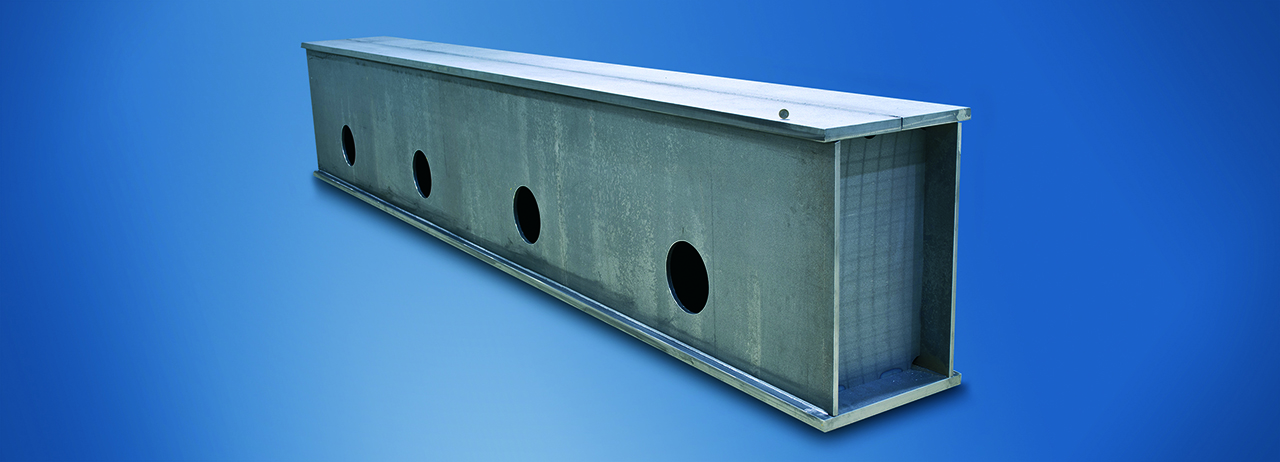

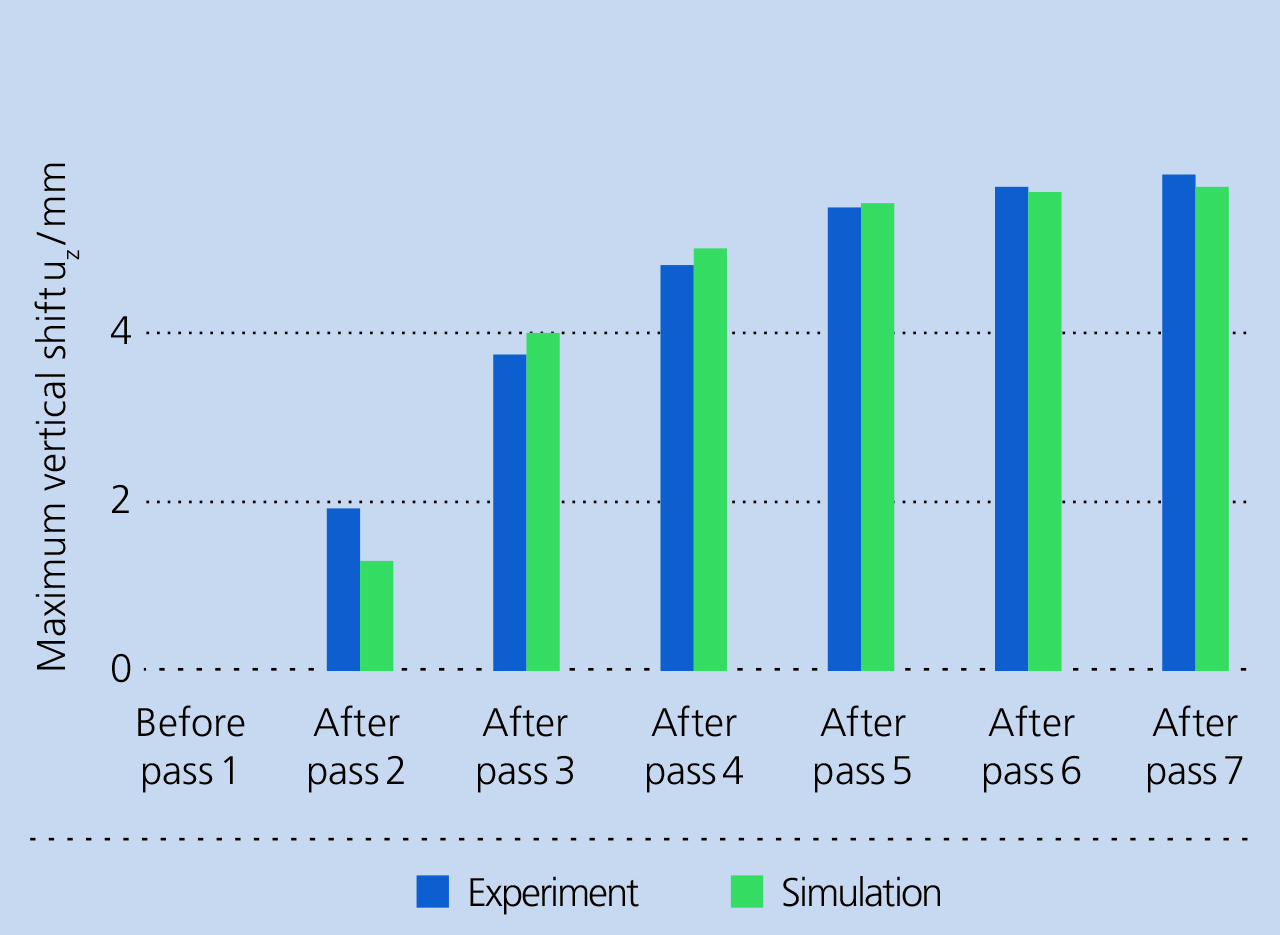

Managed by Fraunhofer IWS in cooperation with three medium-sized companies, the project, funded by Saxony's State Ministry of Economic Affairs, Labor and Transport, has been successfully implemented. The holistic research approach for steel construction, in which a thermal distortion simulation supports the development of the laser beam welding process, adds a new dimension to the project. The potential of the new welding process is demonstrated by the example of a four-meter-long, fully laser-welded crane segment demonstrator. The partners thus successfully examined potential application scenarios for the participating medium-sized steel construction companies. In steel construction, the current value chain is characterized by complex production steps and mostly manual individual processes, such as metal shielding gas welding (MSG), submerged arc welding (SMAW) and intensive straightening processes. “The project team's results demonstrate that, with laser-optimized design, a box-shaped overhead crane segment featuring corner and butt-welded joints up to 30 millimeters thick can be laser-welded with low distortion”, reports Dr. Dirk Dittrich, Team leader of the Laser Welding Team, proudly.

The advanced laser multi-pass narrow-gap welding (MPNG) process completely joins the sheet cross-sections from one side, avoiding time-consuming component turning during assembly. A further advantage here involves the fact that the widely used plasma cutting process can be further employed to cut the semi-finished sheet to size. The process-related low opening angle of the seam preparation of twelve degrees also ensures a small seam volume and thus significantly reduces filler material as well as heat input and component distortion.

On the future of steel welding

Compared to conventionally welded crane segments, cost-intensive straightening processes are mainly avoided. Dittrich explains: “A modern medium-power diode laser with maximum ten kilowatts permits safe welding with filler wire. The newly developed laser protection device, mounted directly on the welding head, ensures adequate work safety, even in steel construction operations.” Expensive additional equipment, such as fixed walls or even the complete enclosure of the welding area, can be largely avoided in the future. The cost-effectiveness of the laser process is significantly higher compared to conventional welding methods due to shorter welding times and the fact that straightening work is no longer required.

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS