Manuel Reif wins award for his research on fiber-reinforced plastic composites

Functionalization of fiber-reinforced plastic composites by means of thermal spraying

Functionalized fiber-reinforced plastic composites are to replace metals – that is the goal of the team headed by Manuel Reif. The researcher from the Thermal Spraying group has now been awarded the Oerlikon Metco Young Professionals Award for his research in lightweight construction. The scientists have developed a solution for functionalizing fiber-reinforced plastic composites so that they can also be used in applications previously dominated by metals. Using the example of an aircraft wing, they demonstrated how thermal spraying can be successfully used to apply multilayer heating systems and reduce weight at the same time.

Due to their outstanding mechanical properties and increasingly efficient manufacturing processes, fiber-reinforced plastic composites (FRP) have become an indispensable part of modern lightweight construction concepts. They exhibit high specific stiffnesses and strengths, predestining them as materials in lightweight construction applications. The functionalization of FRP in particular is the subject of considerable interest in the global research community. The team led by Manuel Reif, a researcher from the Fraunhofer IWS Thermal Spraying group, has succeeded in preparing FRP for subsequent functionalization by means of thermal spraying using a peel ply. Lightweight concepts based on FRP can thus be used wherever metals have so far been superior due to the medial requirements. In a first concrete application, the team managed to coat FRP aircraft wings with a multilayer heating system (anti-icing function). The use of FRP reduces the weight of components such as wings and thus lowers the fuel consumption of aircraft. Ambitious climate and environmental targets in aviation can thus be achieved more easily in the future.

Innovative peel ply provides prerequisite for a wide range of applications

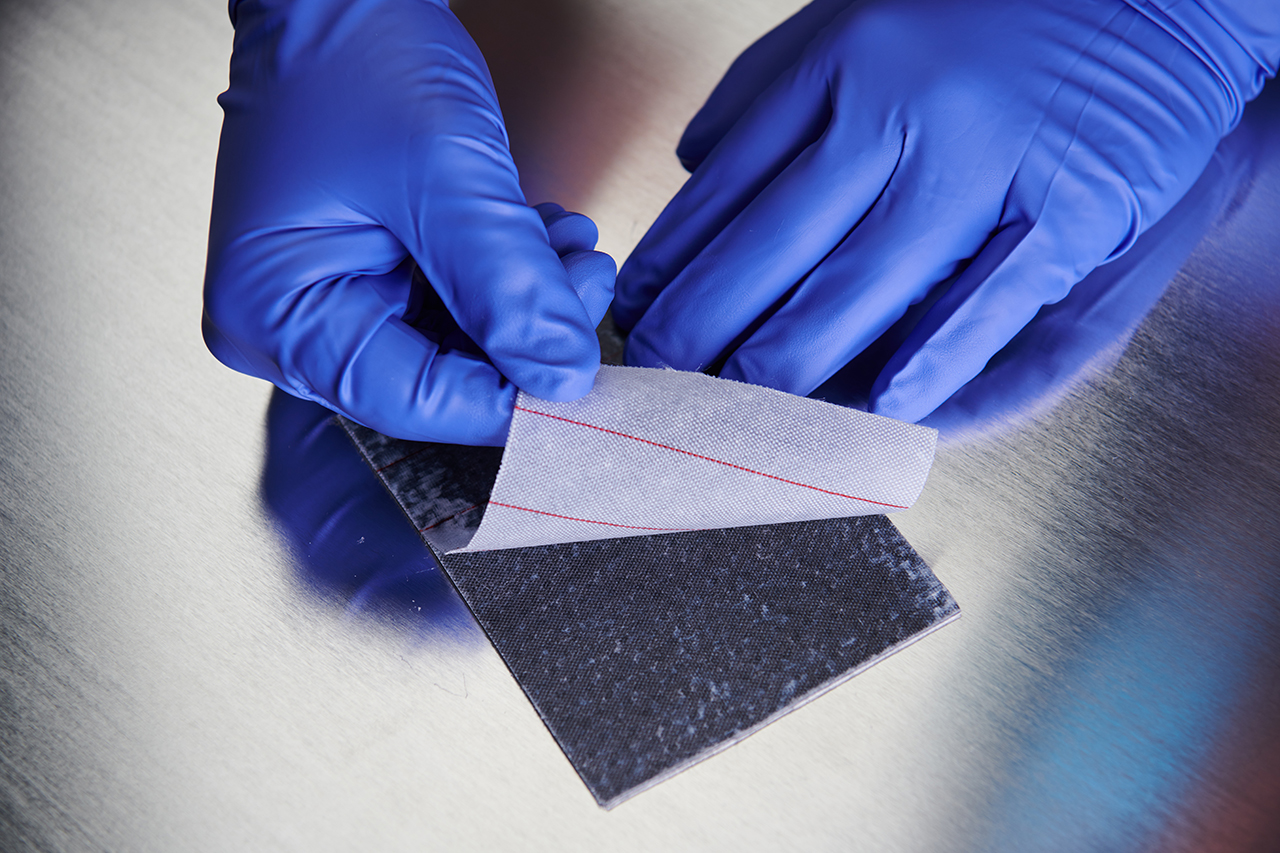

Thermal spraying involves processes in which spray particles are melted on, on or off inside or outside spraying equipment and are sprayed onto prepared surfaces. ”The biggest challenge was initially to implement extensive process adaptations in order not to damage the sensitive FRP surfaces during thermal spraying,” reports Manuel Reif. ”In a further step, the surfaces had to be prepared in such a way that sprayed-on coatings will also adhere permanently.” Until now, the latter has been achieved using sandblasting – a process that is generally of limited use for FRP because the surface is too severely attacked by sandblasting. A newly patented ”preparation process with peel ply” provides a remedy. This involves a nylon fabric that is applied to the FRP surface during production and then removed again before coating in order to roughen the surface in a defined manner. The novel pretreatment avoids any damage to the substrate and – unlike laser structuring – can already be used during the manufacturing process of FRP components.

In combination with the flexibly applicable atmospheric plasma spraying, not only a wide variety of coating materials can be processed, but also numerous functional coating properties can be created on FRP. ”The range of potential industrial applications is very broad. With the help of our process, for example, metallic properties can be generated on FRP surfaces that are electrically conductive and thus protect against electromagnetic influences,” emphasizes Reif. In addition to self-cleaning and electrically heatable coatings, protective coatings can also be realized. ”In the future, we can also transfer the positive project results for heating aircraft wings to wind turbine blades for deicing. In addition, our process for component functionalization can be applied wherever weight is a key factor – for example in the automotive industry, train transportation or shipbuilding.”

Oerlikon Metco honors research results

Swiss company Oerlikon Metco has honored Manuel Reif with the Young Professionals Award for his innovative surface modification and the functionalization of FRP realized as a result. The award ceremony took place during the International Thermal Spray Conference 2021 (ITSC). Reif won out over ten other applicants with his convincing online presentation. Included is a cash prize and the opportunity to visit Oerlikon Metco at one of its sites. His presentation on the coating of FRP with a multilayer heating system can be watched below.

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS