The process-determining tool laser must always be considered as a combination of beam source and processing optics. The optics used must be able to preserve the properties of the laser beam and shape them for the machining process.

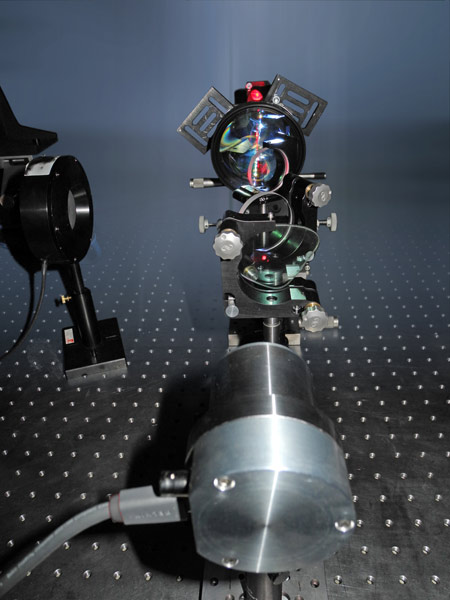

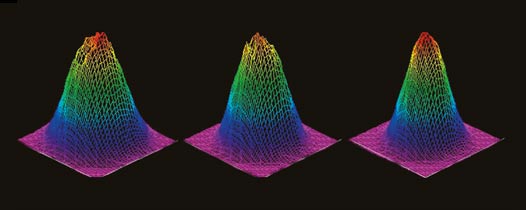

In the field of research and development, laser beam diagnostics is a common method for characterizing and describing imaging parameters of the laser beam sources and optics used. With the help of the three-dimensional measurement of the intensity distribution of the laser beam at the operating point, it is possible to determine system and technological parameters as well as error causes resulting from the interaction of the beam source and optics.

To ensure high process quality, this is also value-adding for industrial manufacturing. Fraunhofer IWS has the necessary system, process and material know-how and offers a wide range of services in this area.

Offer

- Application-related consulting for the selection of beam sources and processing optics

- On-site beam diagnosis of existing laser systems

- Failure analysis of processing optics

- Evaluation of cooling concepts

- Time-resolved characterization of optical elements in the measurement laboratory

- Consulting for process development and optimization

- Investigation of the suitability of enclosure materials

Solutions for complex tasks are worked out together with the customer.

Analyses on Site at the Customer

When commissioning a laser system, beam source or processing optics, knowledge of the beam properties in the process zone is essential for the successful implementation of the laser application. A supplier-independent consultation in advance enables the application-related selection of suitable beam sources and optical components. The measurement of beam properties according to DIN EN ISO 11146 directly at the laser system allows the comparison to the target configuration. Decades of experience in the field of laser applications enable Fraunhofer IWS to evaluate the results, to analyze errors and to identify the potential for process optimization including the support up to series production.

Analyses at Fraunhofer IWS Measurement Laboratory

The possibility of time-resolved detection of laser beam induced aberrations of optical elements is especially addressed to optics manufacturers and material developers. Ultra-short pulse lasers, CO2 and solid state lasers up to 5 kW as well as diode lasers up to 10 kW are available at Fraunhofer IWS for this purpose..

Various measuring instruments are available for laser beam diagnostics:

- Beam distribution (raw beam measurement, focus measurement and fiber direct measurement)

- Laser power measurement

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS