Scientists at Fraunhofer IWS provided the research neutron source Heinz Maier-Leibnitz (FRM II) at the Technical University of Munich with a special component made of cop-per, high-grade steel and aluminum for its cryostats – cooling systems that are able to maintain extremely low temperatures. Until now, this assembly had to be produced by a complex process involving multiple laser beam welded seams, additional joining elements and a brazed or electron beam welded seam. “But then there were problems with stability and tightness,” explains Dr. Markus Wagner, Group Manager Design and Special Processes at the Fraunhofer Institute for Material and Beam Technology IWS. The magnetic pulse method creates tighter joints within just a few micro-seconds. These joints function reliably both at very low temperatures of down to minus 270 degrees Celsius and also wherever extreme temperature differences occur. Overlaps, which provide even more stability, are also created at the joints.

The technologies previously applied by the researchers at the Technical University of Munich are among the group of fusion welding processes. Metals are fused to create a joint between them. However, these methods rely on the metals having similar fusion points. This is the temperature at which a substance begins to fuse. As Dr. Jürgen Peters, Head of Sample Environment at the research neutron source Heinz Maier-Leibnitz (FRM II) of the Technical University of Munich explains: “The problem comes when we try to create joints between metals that have highly dissimilar fusion temperatures or become extremely brittle when mixed together – aluminum with copper or high-grade steel, for example. The samples welded by the magnetic pulse method provided by our partners at Fraunhofer IWS passed the tightness tests.”

Fast, cost-efficient joining

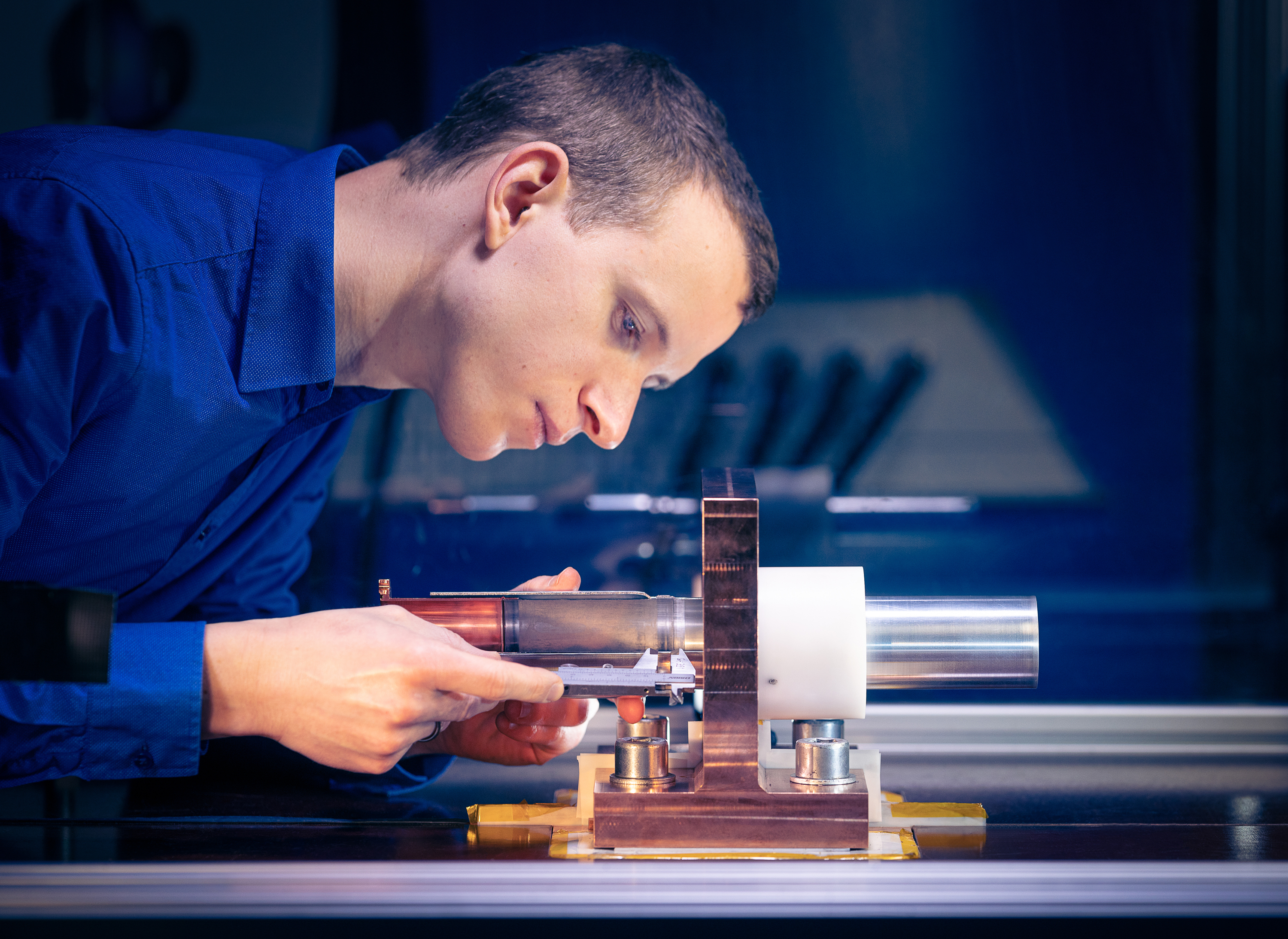

Scientists in Dresden have been researching a new process for several years now. The materials do not need to be fused. “Magnetic pulse welding is not based on a high heat input. The process relies mainly on a high pressure between the joining partners,” explains Jörg Bellmann, expert in magnetic pulse welding in Markus Wagner's group. When the process starts, there is a distance of one to one-and-a-half millimeters be-tween the joining partners. A magnetic field causes one of the two partners to accelerate. In the rest of the process, the metals collide with a bright flash at high speeds – 200 to 300 meters per second. A high pressure is then generated on the joining surface and this ultimately welds the two metals together. A measuring system, likewise developed at Fraunhofer IWS, guarantees throughout all this that the components are correctly positioned, collide at the right angle and that the entire process consumes the smallest possible amount of energy.

Process scores highly with liquid hydrogen

The great advantage of magnetic pulse welding: It can join combinations of metals which, until now have been impossible or difficult to weld together – especially important when it comes to liquid hydrogen applications. Materials with poor thermal conductivity, high-grade steel for example, have to be joined to lightweight construction materials such as aluminum. The new process now makes this possible. “The temperature only really increases at the boundary surface itself,” reports Wagner. The process is said to be fast and cost-efficient and is able to produce joints of a consistently high quality. “We can also employ this method to combine extremely thin-walled components,” adds Bellmann. This is made possible by introducing special supporting elements that can be removed again when the process is completed.

And the new process holds potential for more than just aircraft construction. Its good electrical conductivity in the joining zones also makes it an attractive proposition for the electro mobility sector and for processes in the electronics manufacturing industry. “This welding technology will also create new possibilities for space travel,” of that Bellmann is convinced.

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS