EARTO Award for Microsystem of the Fraunhofer IWS Dresden / 2018

Less animal experiments on the horizon: Multi-organ chip awarded

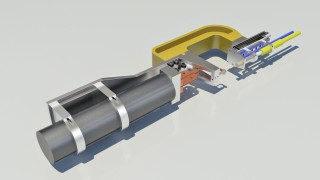

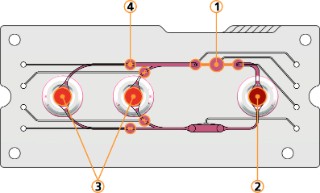

Dresden Fraunhofer engineers have developed a so-called "multi-organ chip". This microsystem from the Fraunhofer Institute for Material and Beam Technology IWS Dresden, which has now received an "EARTO Innovation Award" in Brussels, simulates the blood circulation and the organs of animals or humans.

more info Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS![Dr. Roman Tkachov examines a film printed with two different conductive polymers at a dispensing printer in the Fraunhofer IWS Dresden. "PEDOT:PSS" is a polymer with positive charge carriers (“p-conductive”), while “Poly(Kx[Ni-itto])” transports negative charge carriers (“n-conductive”). This also shows that IWS polymers can be processed using standard techniques such as printers or rotary coating. Dr. Roman Tkachov examines a film printed with two different conductive polymers at a dispensing printer in the Fraunhofer IWS Dresden. "PEDOT:PSS" is a polymer with positive charge carriers (“p-conductive”), while “Poly(Kx[Ni-itto])” transports negative charge carriers (“n-conductive”). This also shows that IWS polymers can be processed using standard techniques such as printers or rotary coating.](/en/newsandmedia/press_releases/2018/presseinformation_2018-12/jcr:content/fixedContent/teaserimage.img.1col.jpg/1539170627844/p13-03f1-getriebebauteil.jpg)