Isobar

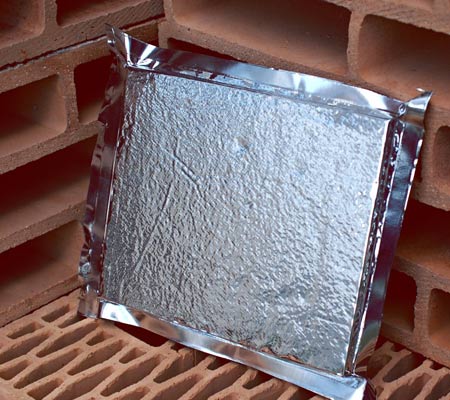

Innovative NIR spectroscopic moisture analyzer, basing on moisture monitoring and control to guarantee optimal process-and system operations (Isobar)

To analyze the gas humidity in natural gas dehydration and freeze-drying processes, the IWS scientists developed near-infra-red sensors, which base on laser diode spectroscopy and Fourier transform near-infra-red spectroscopy. These highly sensitive, non-invasive measuring technologies provide information about process parameters and their realization into the process control.

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS