Developing solutions by means of laser and materials technology to simplify processes and to reduce costs: That is our drive serving small and medium-sized businesses. Cost efficiency results from new or adapted processes, equipment and systems. Therefore it is necessary to analyze and understand the challenges of the partners and to apply the latest scientific findings. We do not only offer easy-to-integrate custom and one-stop solutions, but also the right sparring partners and profound know-how. Future-proof solutions are the result of close interaction between research, development and practice. You contribute to maintaining or even expanding your company's leading market position in national and international competition.

- Do you like to invest in growth and find answers to tomorrow's questions today?

- Do you need support in researching new processes, but either cannot or do not want to invest in research or testing facilities?

- Do you lack the necessary modern technical equipment in certain areas, or cannot find solutions quickly or cost-effectively enough?

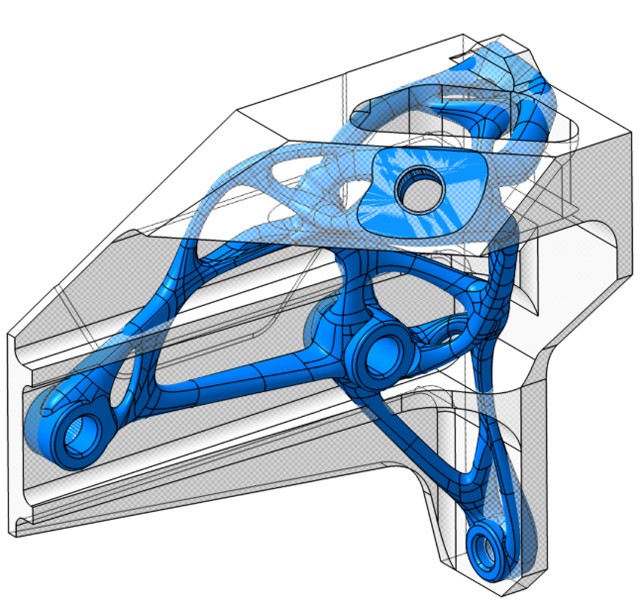

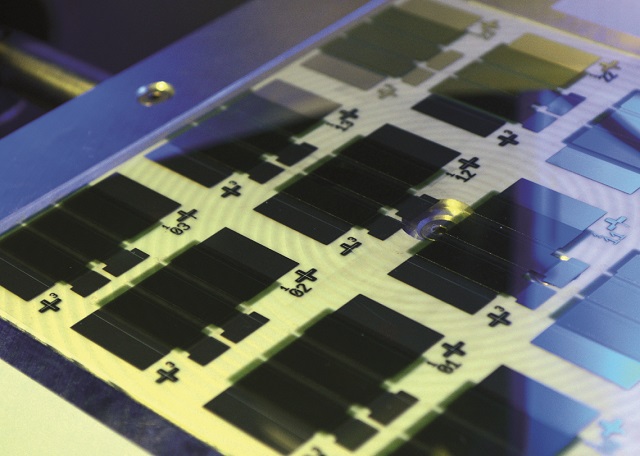

If so, we are here to help. Fraunhofer IWS is equipped with a wide variety of modern technical equipment and systems to develop precisely tailored processes that optimize cutting, welding, measuring or additive manufacturing processes to meet your requirements. We combine profound material and process know-how with laser and materials technology as well as suitable system technology. The particular added value is provided by our scientists with their expert know-how and their ability to successfully meet even complex challenges with new and proven research and development methods. We will be happy to discuss how we jointly can find solutions to your challenges in a personal meeting.

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS