Insights in the Fraunhofer IWS Annual Report 2021/2022

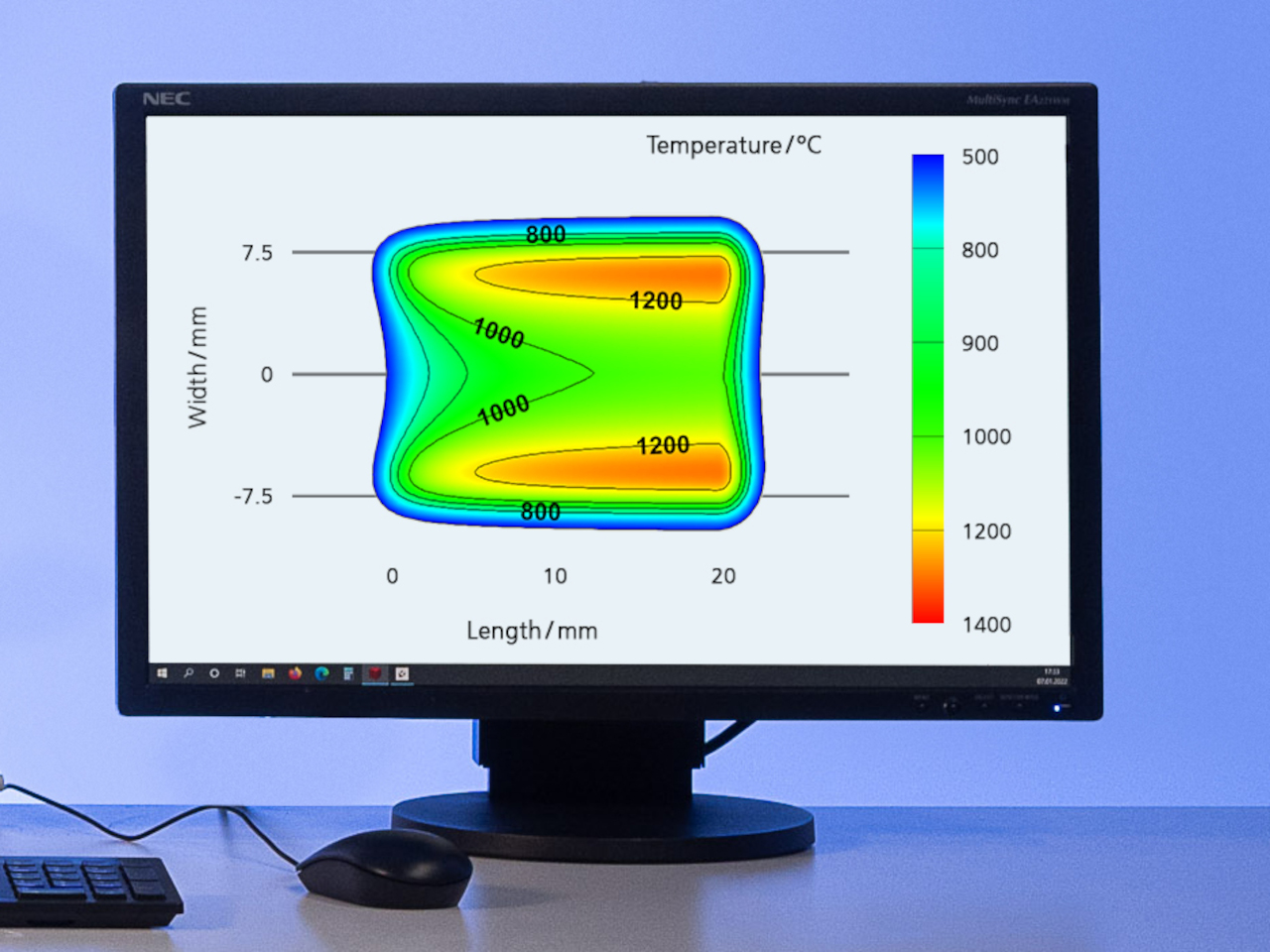

Simulations for 2D laser hardening

Environmentally friendly laser processing is becoming increasingly popular in industry as a means of hardening turbine blades, tools, engine components and other steel components in an energy-saving and stress-resistant manner: Compared to furnace hardening, laser hardening reduces energy consumption by up to more than 90 percent, depending on the component.

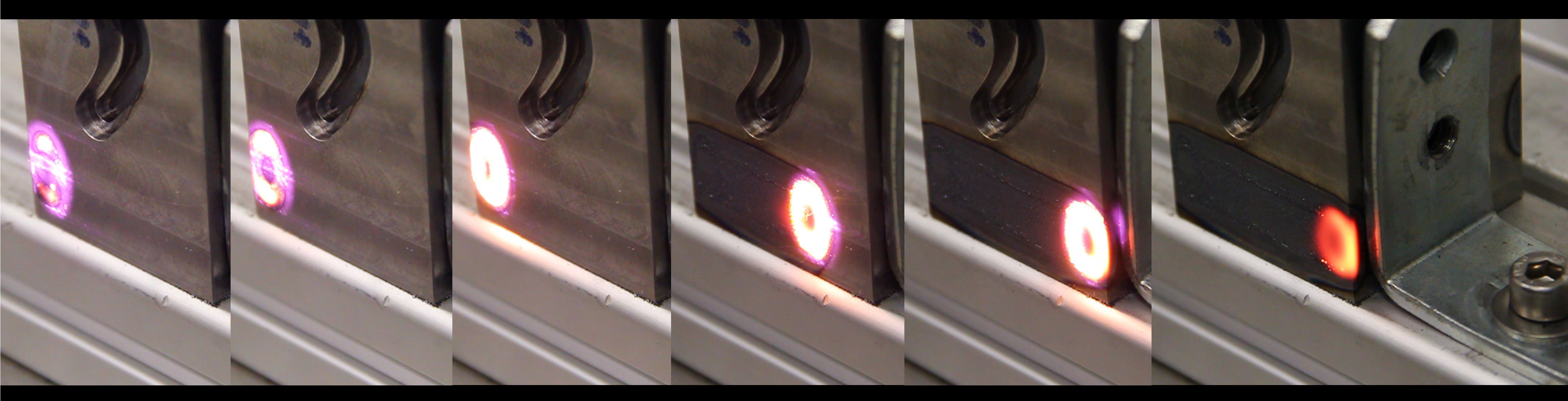

In addition, heat-sensitive components can also be hardened gently. Fast oscillating mirrors guide the laser beam and precisely control the thermal energy input, which often penetrates only a few tenths of a millimeter into the component. It also eliminates the high energy requirements in furnace, flame or induction hardening to quench or annealing components.

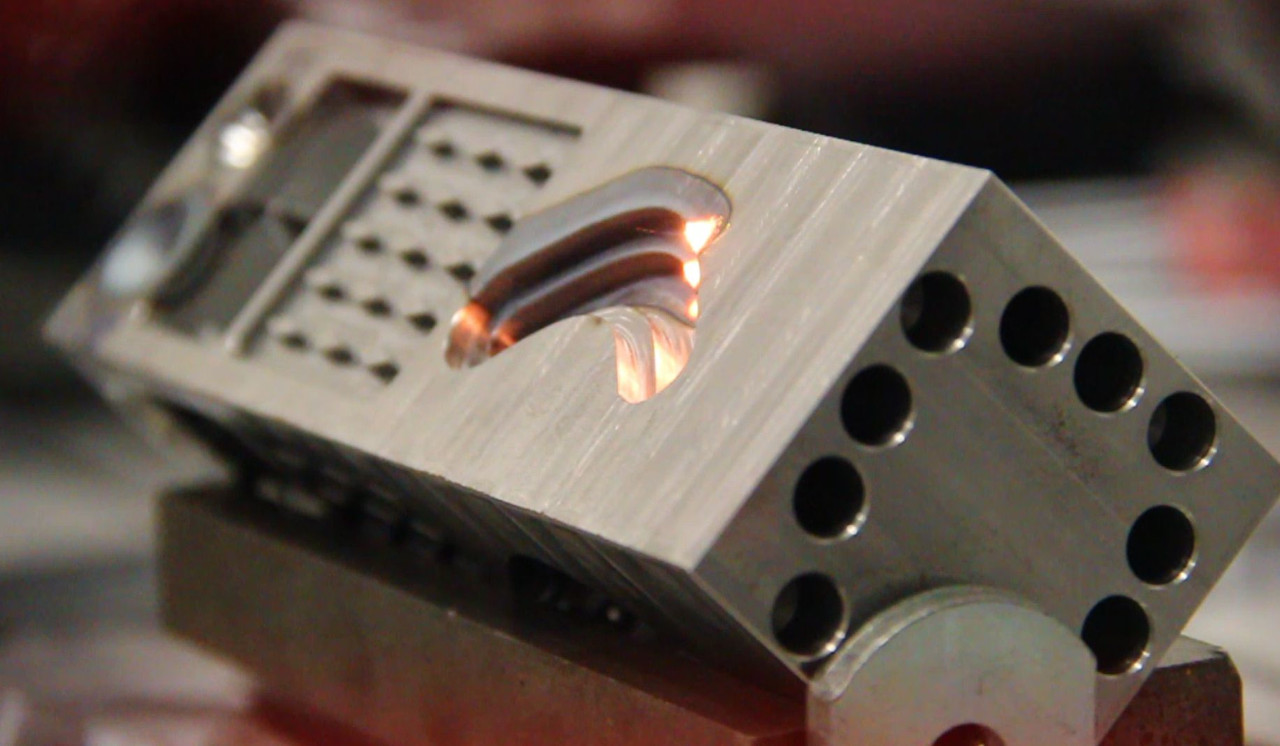

Fraunhofer IWS is cooperating with European partners to open up broader applications for laser hardening by using more complex 2D scan patterns. They aim at particularly compact and inexpensive laser hardening modules for robots and CNC cells. These are designed to guide the laser beam two-dimensionally using only one oscillating mirror instead of the usual two.

2D scan technology for laser hardening of complex shapes

For a deeper understanding of this still young 2D scanning technology Fraunhofer IWS uses its own developed simulation programs. The complex time and position-dependent temperature distributions are simulated to virtually map and evaluate the influence of parameters such as laser power, beam diameter and oscillation pattern as well as frequency. They will focus on the determination of suitable thermal cycles and optimal hardening results. The knowledge is to be incorporated into the design and control of industrially relevant applications in order to be able to laser-harden even complexly shaped components. In the future, artificial intelligence methods are also intended to be used for beam shaping and guidance.

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS