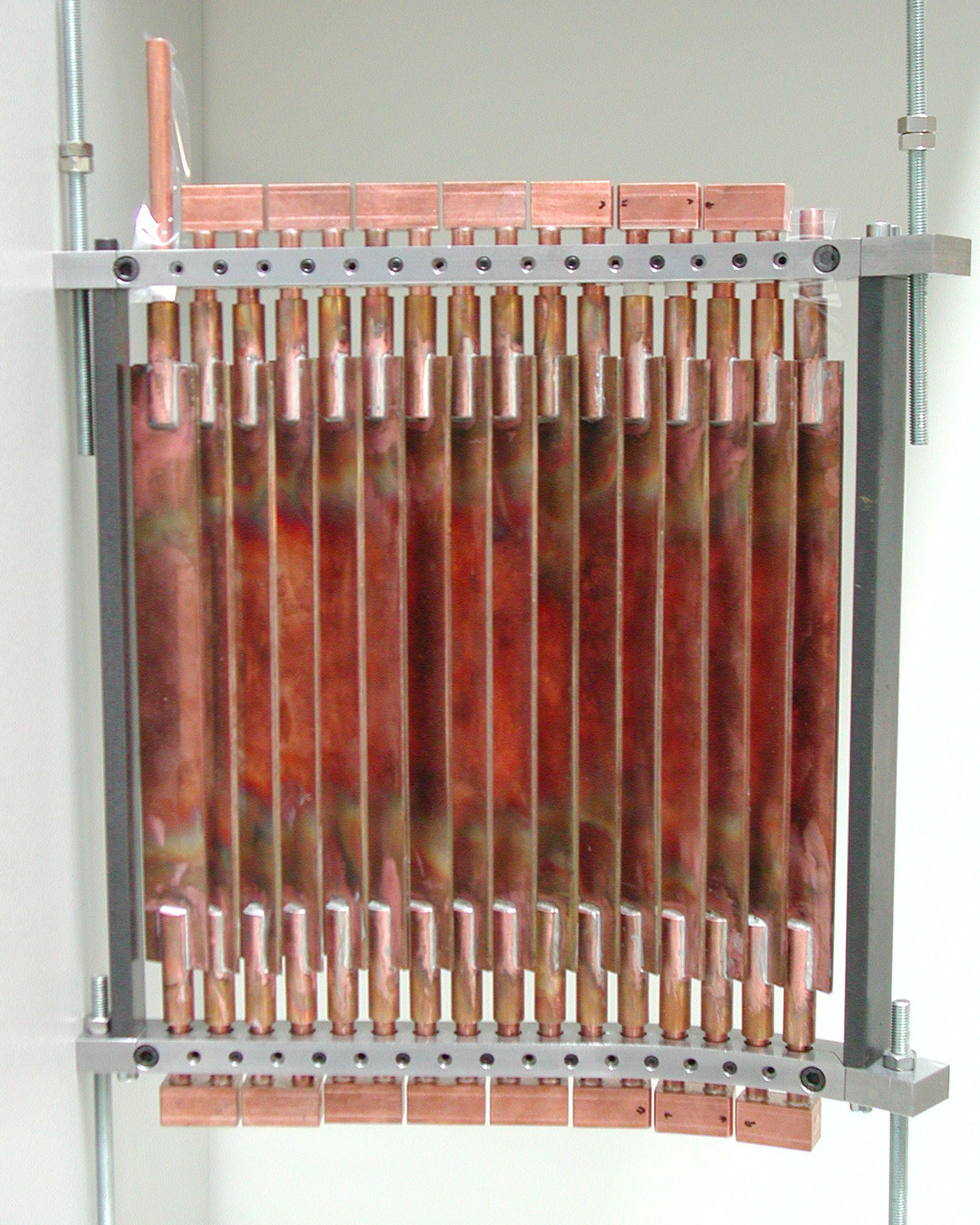

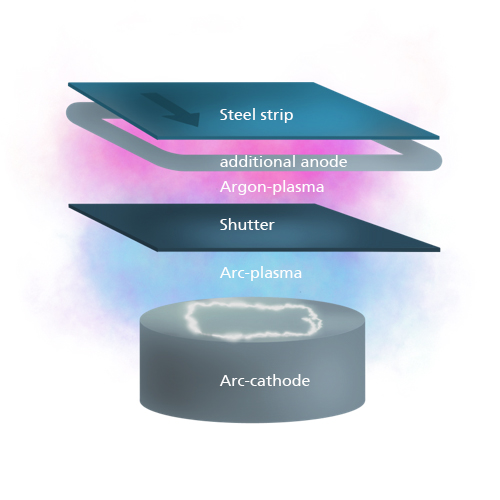

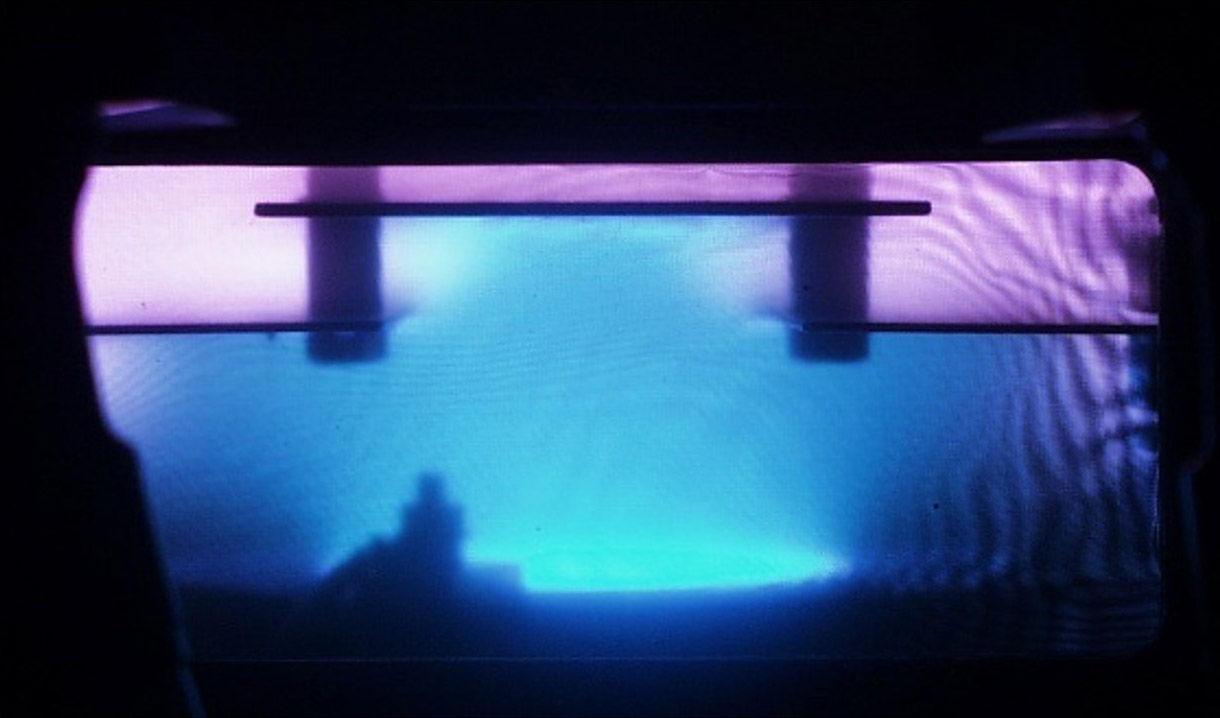

The movement of the cathodic arc spots on the cathode has a significant influence on the process reliability and the effectiveness of the arc PVD process. Their targeted control is possible with the ProArc system ("programmable arc"). Particularly when large-area cathodes are used, the effectiveness and quality of vacuum arc coating can be significantly improved. This system offers significant advantages in particular with regard to:

- Cathode utilization

- Coating thickness profile and homogeneity

- Plasma characteristics

- Process stability

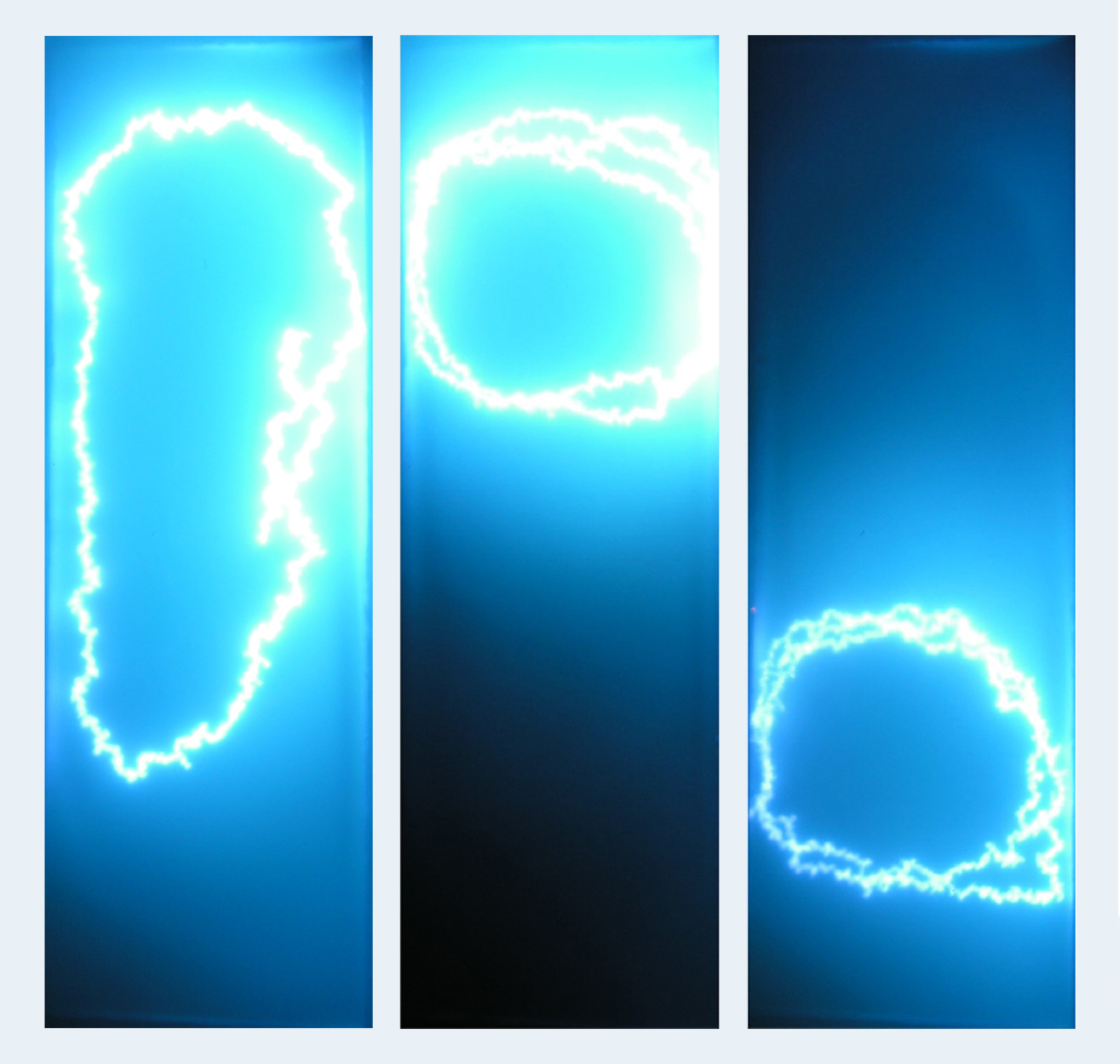

The control of the arc spot movement is realized via a programmable magnetic field and can generate different arc spot paths within fractions of a second.

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS