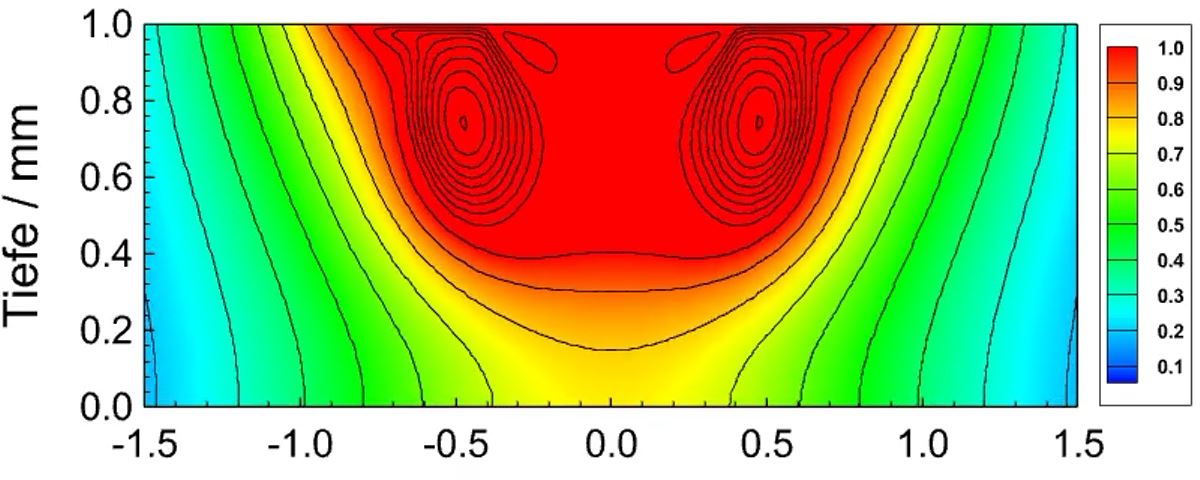

Based on thermodynamic principles, the simulation of laser-based manufacturing processes, e.g. laser cutting and welding as well as micro material processing, is carried out. In comparison with the real process and competing technologies, conclusions can be drawn about energy efficiency and achievable process efficiencies. Complex interaction processes in laser material processing are mapped virtually using model developments. Variation calculations and sensitivity analyses make it possible to describe functional dependencies between control, influencing, disturbance and target variables of a laser material processing process.

Our Range of Services Includes:

- Analysis to describe functional dependencies between control, influencing, disturbance and target variables of a laser material processing process

- Development of simulation models for the virtual representation and investigation of thermal, fluid-mechanical and gas-dynamic processes in laser material processing

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS