Insights in the Fraunhofer IWS Annual Report 2021/2022

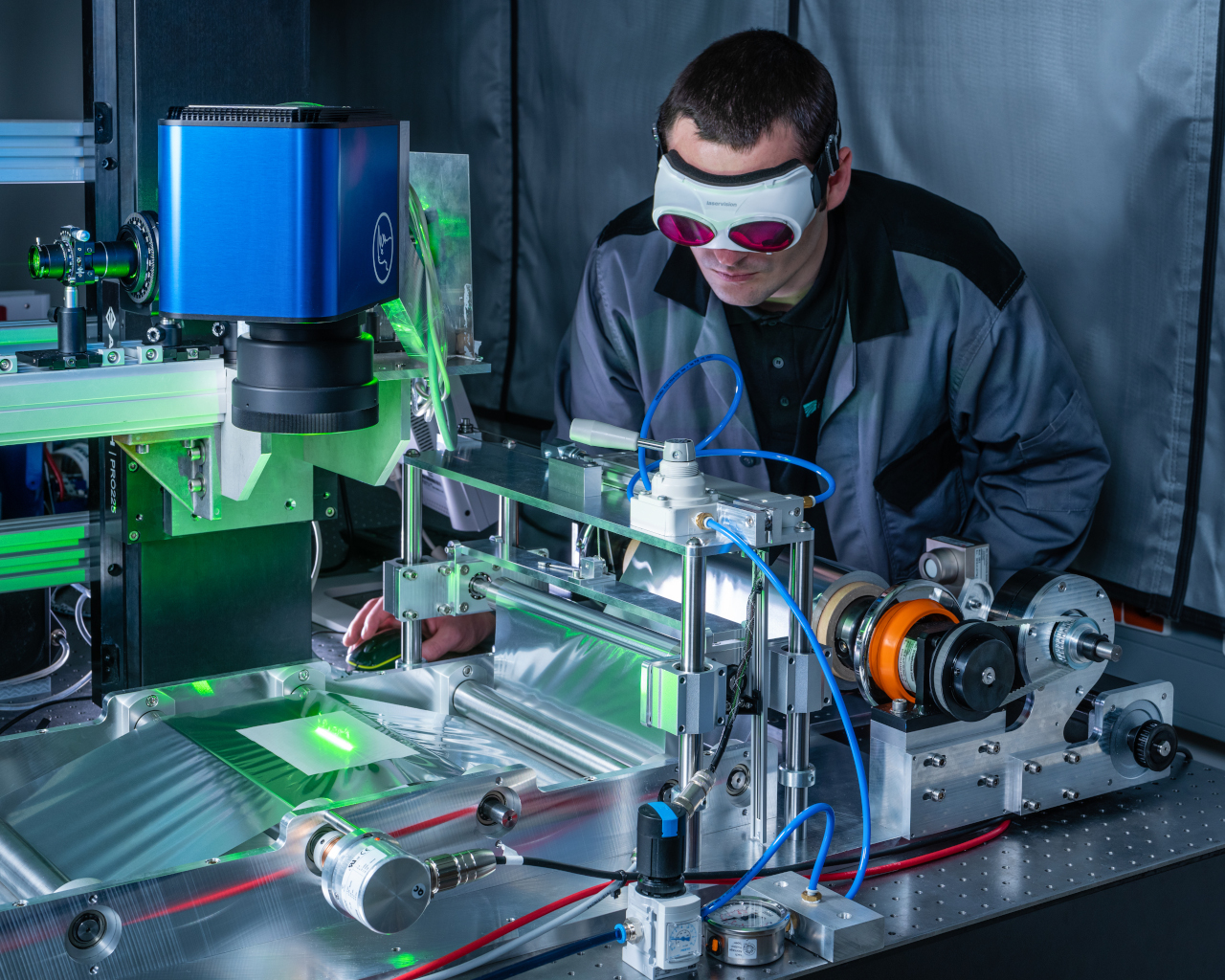

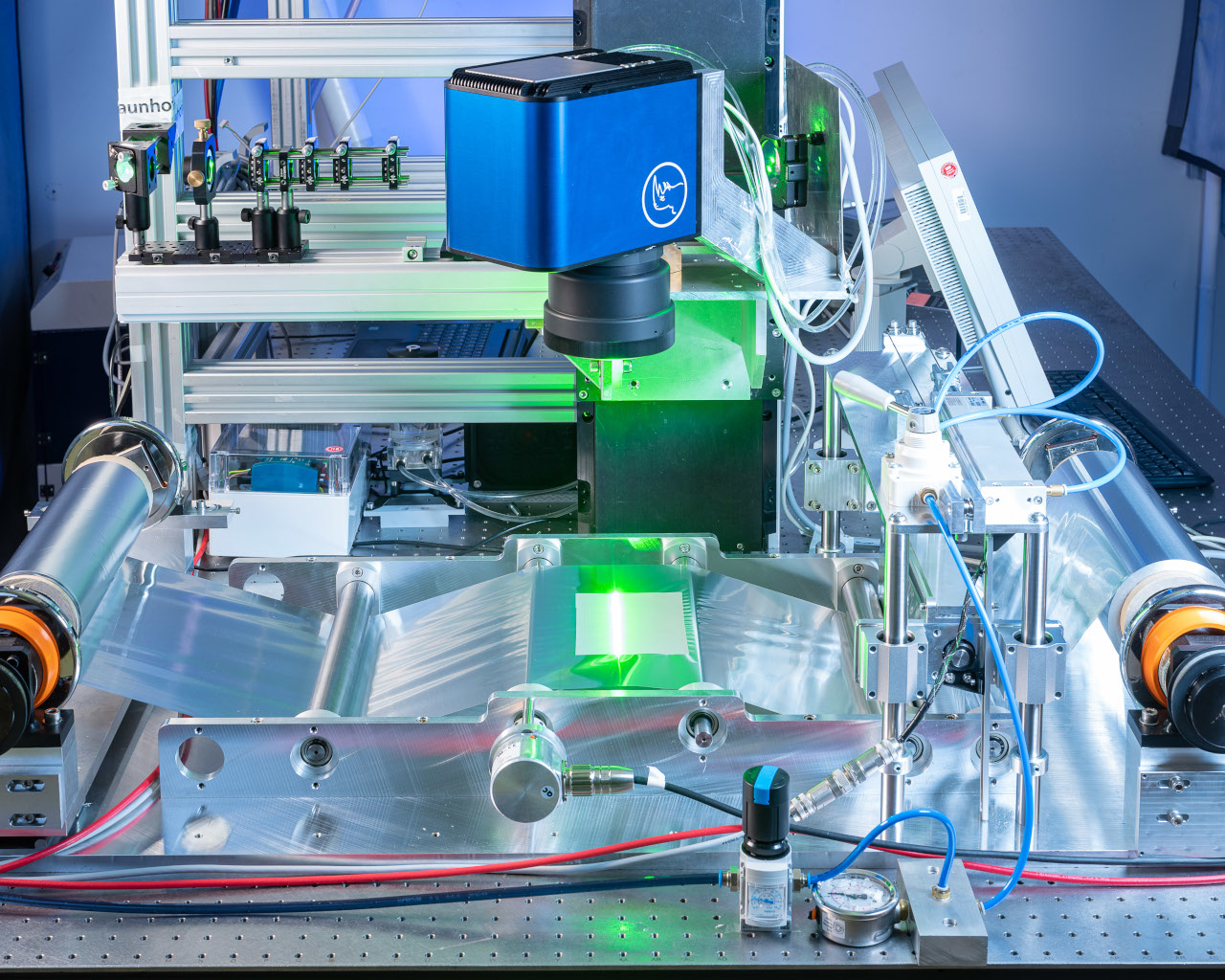

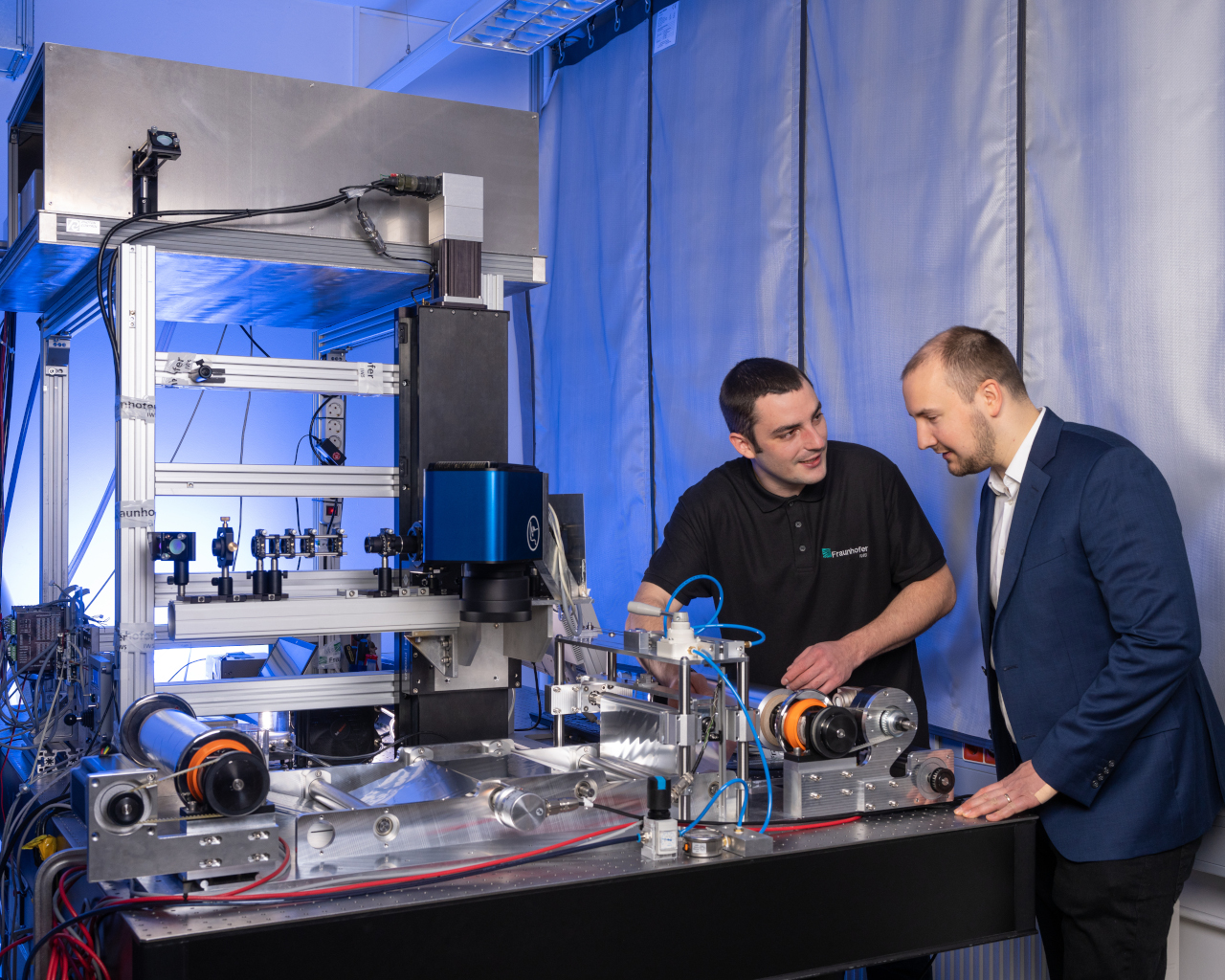

Better batteries thanks to DLIP on new roll-to-roll system

“Direct laser interference patterning“(DLIP) can be used to add new functionalities to the surfaces of conductor films in batteries: The interference patterns can increase the reaction area and improve the adhesion of the metal foils. Thereby, more possibilities open up for battery manufacturers to increase the lifetime and capacity of their energy storage devices and, at the same time, the range of electric cars.

Fraunhofer IWS and Technische Universität Dresden have continuously advanced this laser structuring process over the past years. The focus is now increasingly on the demand to improve the processing speed of DLIP systems and to reduce their form factor. This is exactly the aim of the project “Next-Gen-3DBat”, in which Fraunhofer IWS and other industrial partners are cooperating under the leadership of the project management organization Jülich. By means of 3D laser structuring of cell components, researchers want to optimize the performance and capacity of batteries.

Lightning-fast structures for current conducting foils

Fraunhofer IWS is transferring its patented laser interference patterning process to the roll-to-roll principle. The new system is designed to continuously unwind and structure current conductor foils from rolls. Compared to cycle processes, the goal here is to shorten processing times. The project partners expect throughputs of around one square meter per minute. In addition, the coils commonly used in industry can be further processed. A prototype is operational, and an improved system is under construction. Fraunhofer IWS is also pursuing another innovative approach: the laser beam is optimized by a combination of several beam shaping methods to produce a high aspect ratio and a uniform interference pattern on the current conductor foil. This significantly increases the area processed with each ultrashort pulse.

Funding notice

The development of the roll-to-roll system for the functionalization of battery foils within the project ”NextGen-3DBat” was funded by the German Federal Ministry of Education and Research on the basis of a resolution of the German Bundestag under the grant number 03XP0198F.

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS