Resource-Saving, Current-Conducting Connections for the Energy Turnaround (Ampere-Clinch)

Motivation

The Ampere-Clinch multi-part research project aims to qualify the mechanical and energy-saving joining process clinching for use in current-conducting connections and thus make a decisive contribution to technical electrification and resource conservation.

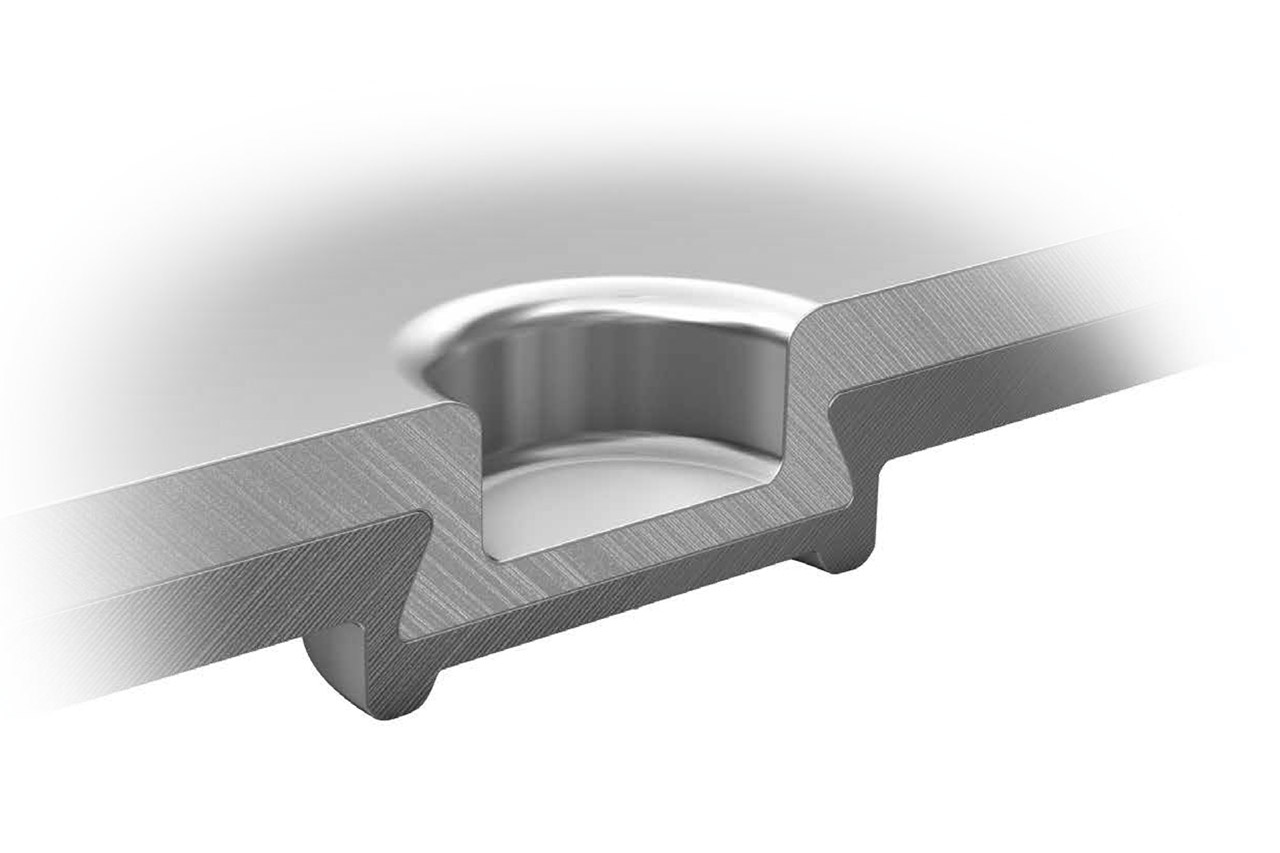

The joining process is energy- and resource-saving in itself, since it does not require any auxiliary joining parts or filler materials. It can join dissimilar materials and can be used for different material thicknesses, making it an ideal and economical process with regard to industrial lightweight construction and the associated energy savings.

Project Goals

Current-conducting joints must primarily have the ability to conduct electric current with the lowest possible power dissipation. This capability has already been demonstrated on clinched joints made of copper and aluminum materials. In addition, the mechanical load capacity of the joints is a crucial issue for users. Such joints are subject to very frequent recurring mechanical stresses in use, for example in the field of e-mobility. For this reason, particular interest is focused on the fatigue strength of the joints in terms of structural integrity and, at the same time, on the durability of the electrical properties in the final application. Both questions are currently of great industrial interest and cannot be adequately answered with current scientific knowledge.

Within the scope of the project, aluminum and copper alloys are evaluated with regard to their suitability in current-carrying clinch connections. Aluminum alloys are used as primary and secondary materials, which means that the potential conservation of resources is already addressed in the selection of materials.

Focal Points of the Joint Project

- Determination of the clinchability of conductor materials and technical alloys of aluminum and copper

- Characterization of the forming behavior of the materials during clinching --> Fraunhofer IWS

- Determination of the fatigue properties of the materials as a function of the degree of forming --> Fraunhofer IWS

- Analysis of the power loss of the clinched joints at different stages of fatigue loading

- Creation of a service life prediction model based on extensive fatigue tests on clinch joints

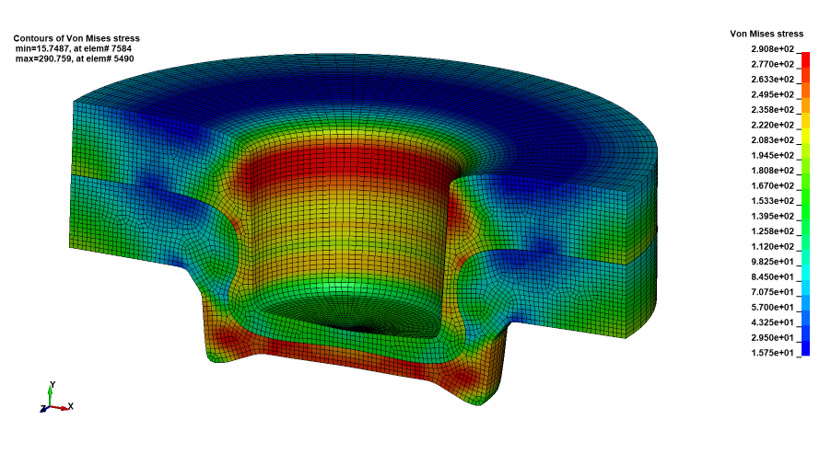

- Creation of a simulation model of the clinching process based on the experimental data

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS