Service offer

Holistic processing of joining tasks for material and form-fit connections between conventionally difficult-to-weld materials and between dissimilar materials (e.g. Al-Cu, Al-St, Al-CFK, ...) by means of:

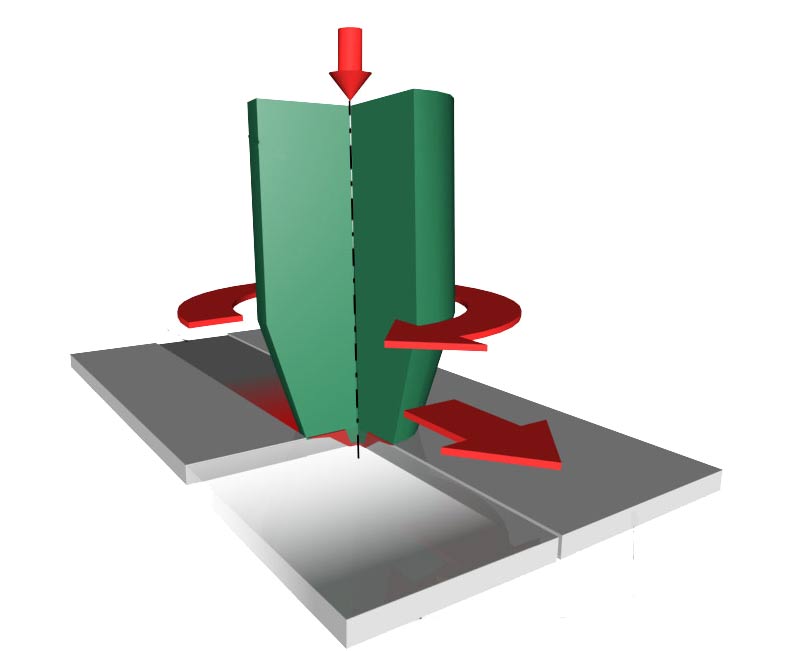

- Friction Stir Welding (FSW)

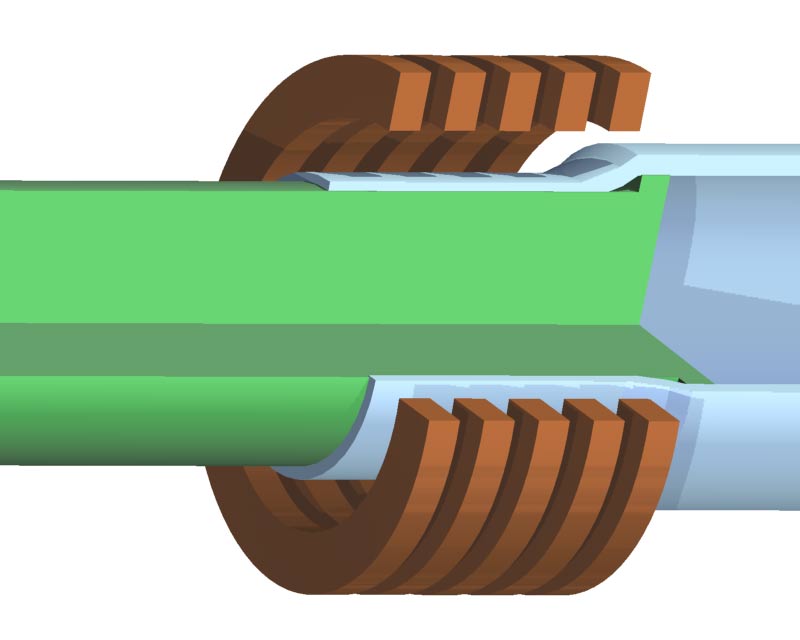

- Magnetic Pulse Welding (MPW)

By means of our customized joining processes, magnetic pulse welding and friction stir welding, we generate material- and form-fit connections between conventionally difficult-to-weld materials as well as between different types of materials (e.g. Al-Cu, Al-St, Al-CFK, ...) We are leading in offering comprehensive solutions, starting with joining design and joining process development up to the evaluation and testing of the joining properties of real components. Our expertise includes the development of tooling, measuring and systems technology and enables us to develop optimal solutions for joining tasks and to implement them in series production together with the customer.

The benefits of our expertise are very complex:

- Innovation: Production of lightweight multi material structures

- Cost and time saving: Minimization of welding time

- Safety: Securing and improving the joint strength

- Sustainability: Low-energy joining

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS