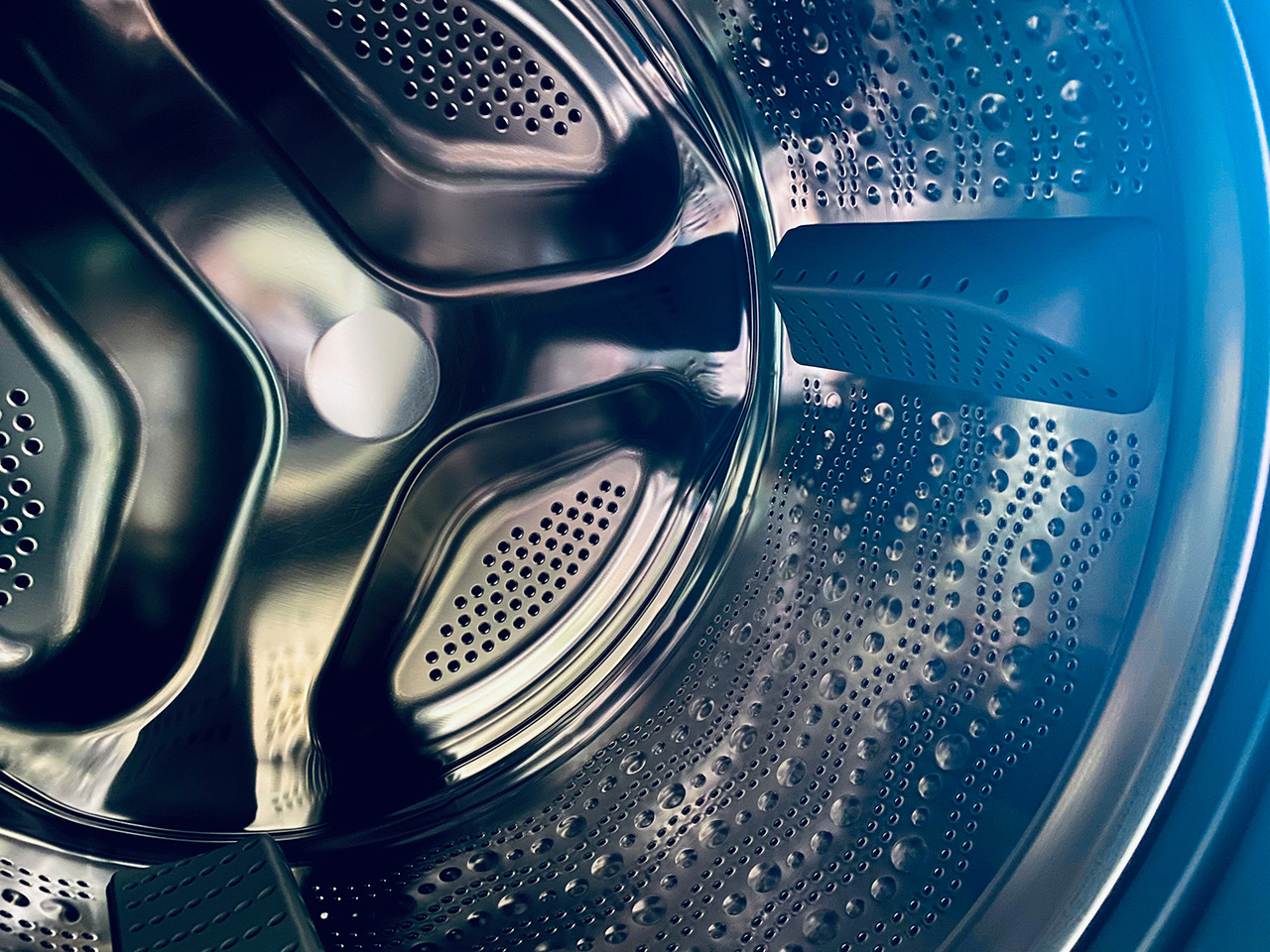

Laser welding of thin sheet approx. 1 mm and of foils up to 50 µm for various applications, e.g. washing machine drums.

Efficient and flexible welding solutions are required for consumer goods, which can be used for the mass production but also for individualized single products - with short process times, economically reproducible and in the highest quality. The range of materials extends from high-alloy steel materials for wear-stressed gardening equipment and corrosion-resistant stainless steels for hygiene products to aluminum and magnesium materials for weight-optimizing housing components or electrical contacts in mobile devices. Joints made of different material combinations can be found in heat exchangers, which are used in particular for so-called White Goods products or heating systems.

Advantages of laser beam welding

Process

- Geeignet für Serienfertigung und individualisierte Produkte

- Berührungsloses Verfahren und geringe thermische Beeinflussung von Werkstoffeigenschaften

Component properties

- Low distortion, bending resistant components with high functional integration

- Highly load-adapted welded joints (torsional moment, tension-shear loaded joints)

- Mechanical and metallographic characterization of selected process approaches

Application examples

- Garden equipment, e.g. chain saws

- Household appliances, e.g. washing machine drums, hair trimmers

- Welding of lithium battery contacts, e.g. for mobile household appliances

- Stainless steel structures, e.g. containers for commercial kitchens

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS