Data-Driven Process, Material and Structural Analysis for Additive Manufacturing (AMTwin)

Motivation

Additive manufacturing (AM) processes offer the potential to flexibly manufacture components with a high degree of lightweight design that are optimized in terms of load path and material. AM enables completely new component concepts whose load capacity must be reliably estimated. In terms of applications, it is expected that the number of these components will rise sharply in the coming years. Against this background, the increasing demands on the application properties of these components must be implemented in terms of materials, design and production technology.

Project Objective

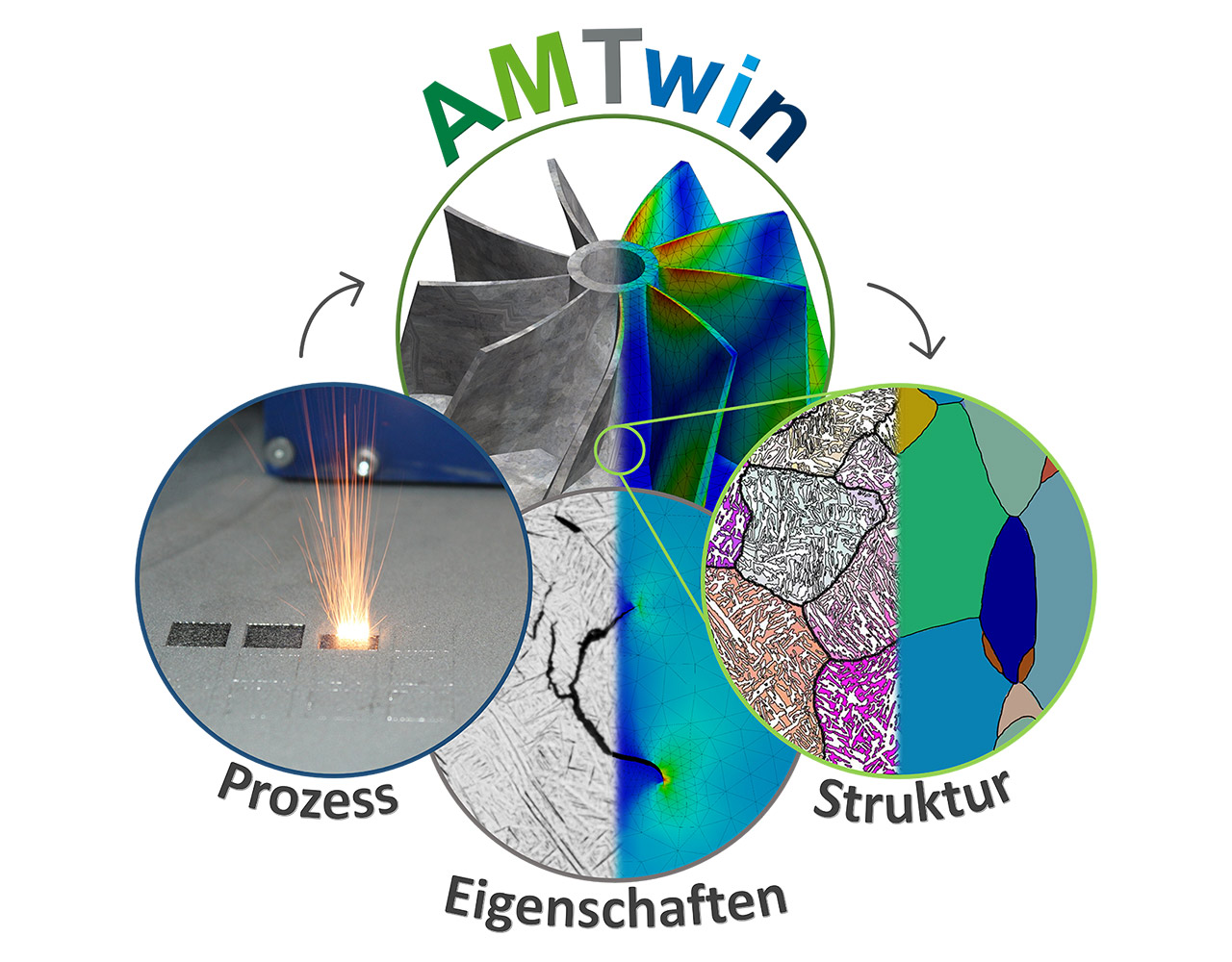

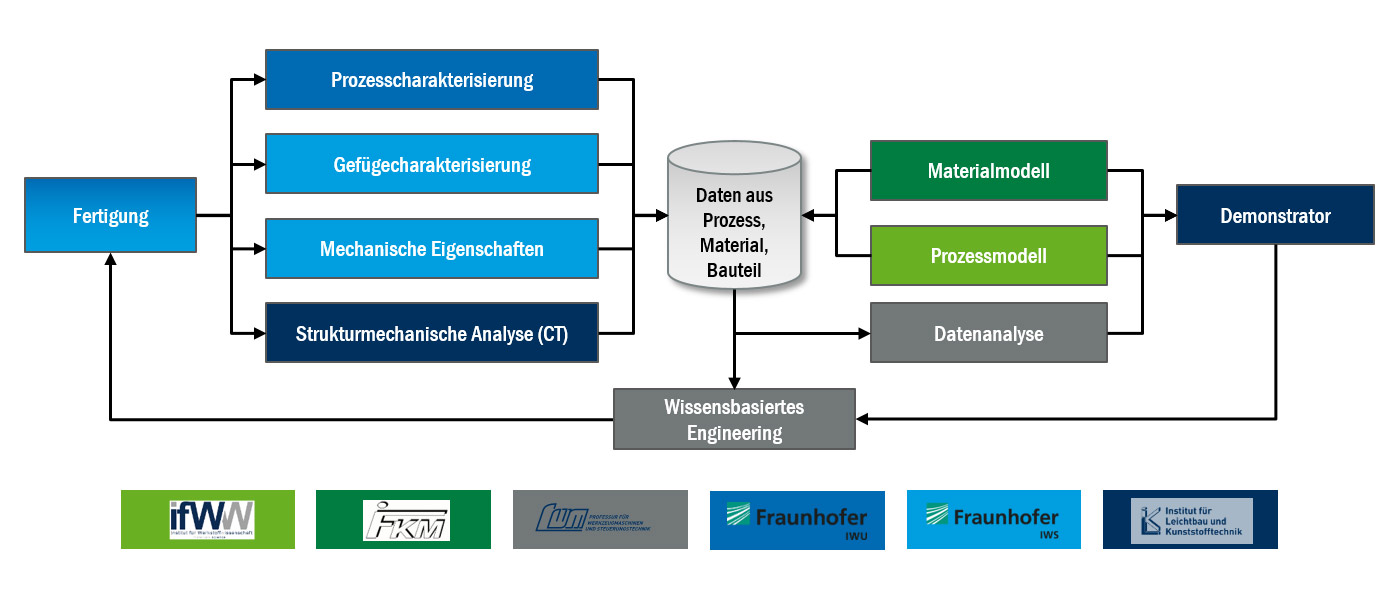

A fundamental challenge in the transfer of AM into resource-efficient, economical and reliable industrial application lies in an insufficient and so far too little systematized knowledge of process-structure-property relationships. Due to the process, AM components often exhibit imperfections and inhomogeneities that lead to premature failure, especially under cyclic operating loads. Therefore, a further development of the methods for material qualification, structure and process simulation as well as for component design and quality assurance is necessary. This further development is being driven forward in a targeted manner in the AMTwin joint project.

Innovations and Perspectives

The reason for the insufficient forecasting capability is the multitude of physical phenomena, statistical influences and boundary conditions that cannot be captured in model-based simulations. In this context, the rapidly advancing digitalization in materials and production technology enables completely new approaches to investigating the relationships between process parameters, microstructure and component properties. By consistently acquiring material, process and component data, the AMTwin project is creating a so-called digital twin, i.e. a digital image of the AM process that can be used for monitoring and optimization. In this context, the analysis of future available data with machine learning methods offers a high innovation potential, which will be exploited in this project for the quantitative mapping of process-structure-property relationships for AM components under static and cyclic loading.

Work Content Fraunhofer IWS

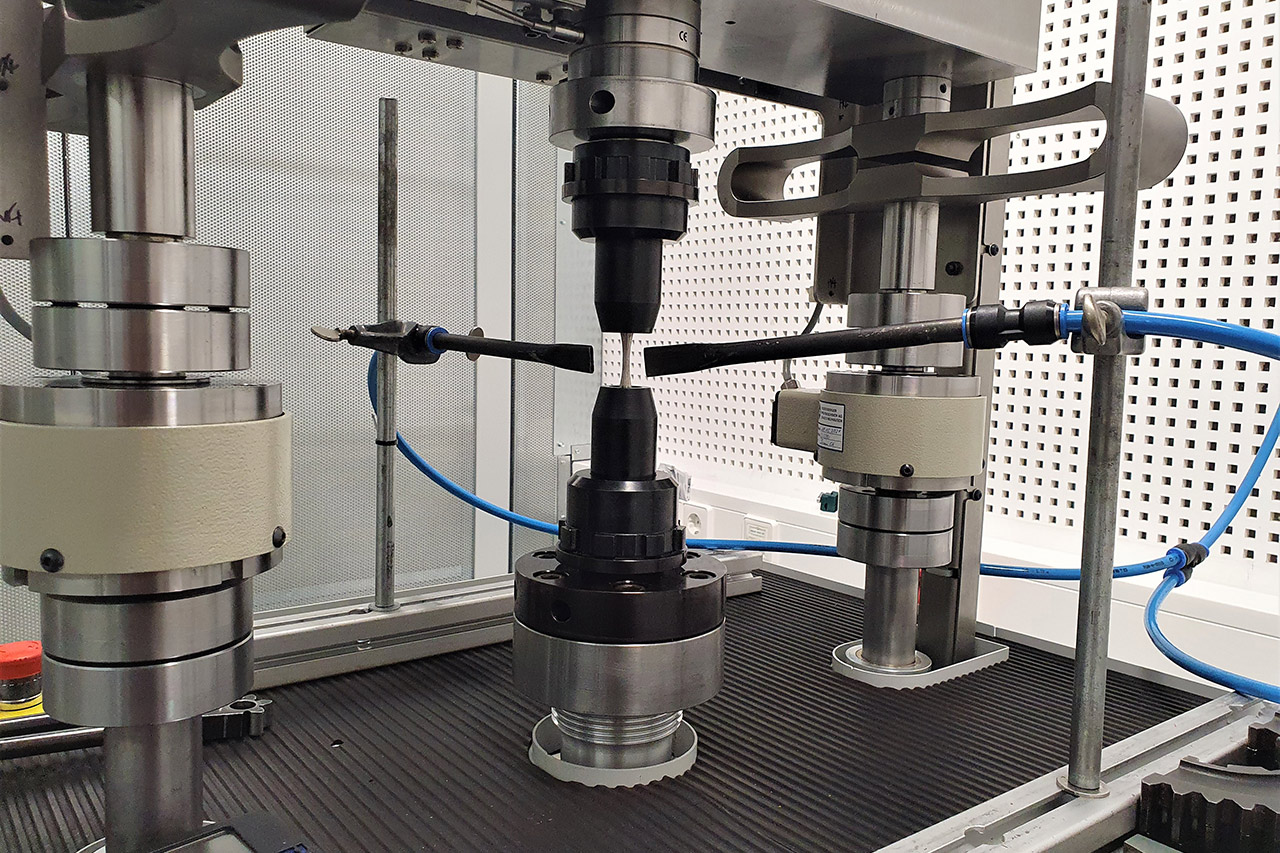

The Fraunhofer IWS contributes its process engineering and materials know-how to achieve the goal by performing systematic parameter variations in the additive manufacturing process and analyzing their effects on the resulting material structure and properties. A major focus is on the occurring process - structure - property correlations, taking into account the failure-causing structural features in the case of cyclic mechanical loading.

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS