Safety in warehouse logistics / 2022

New Fraunhofer safety technology reduces transportation accidents

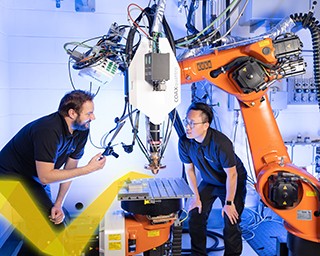

Warehouses are home to heavy volumes of traffic. The numbers of industrial trucks (pallet trucks, forklift vehicles and the like) traversing their aisles are growing especially large – in facilities that are themselves increasing in size all the time. Under these conditions, accidents become an inevitability even if numerous safety measures are put in place. Now, optical sensors on industrial trucks might provide warehouse staff with better protection as they do their jobs. Joining forces with BASF SE and Kinotex Sensor GmbH, the Fraunhofer Application Center for Optical Metrology and Surface Technologies AZOM has developed prototypes designed to ensure added safety during day-to-day activities.

more info Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS