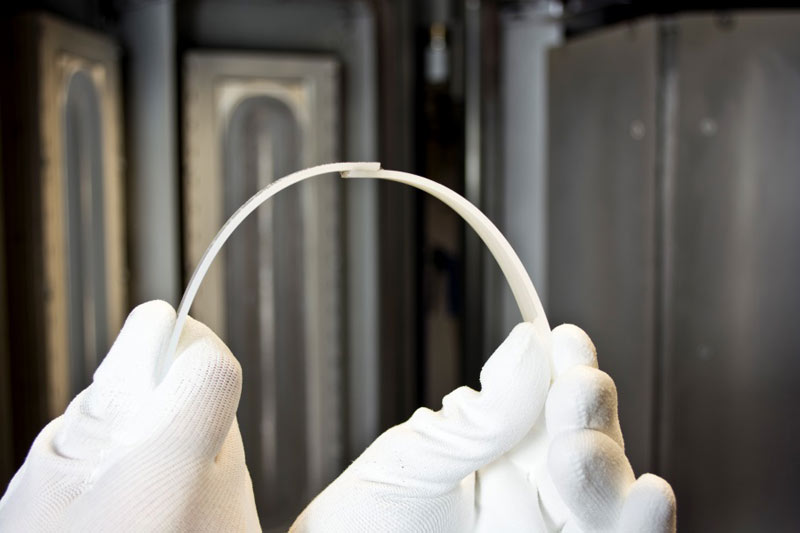

By using reactive multilayer systems (RMS), many materials, including metals, ceramics, semiconductors and polymers, can be joined in a material-friendly, low-stress and very fast manner. For this purpose, an RMS directly adapted to the joining process is placed between the two components to be joined and then activated. A chemical, self-propagating reaction occurs, as a result of which heat is provided for joining the components for a very short time and in a narrowly localized manner.

Our Range of Services Includes:

- Development and production of reactive multilayer systems (RMS)

- Joining application by means of RMS

- Characterization of RMS and reactively joined components

- Simulation of the thermal balance of an RMS joint using COMSOL Multiphysics®

- Coatings and solder deposition by magnetron sputter deposition

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS