Exponentially growing data volumes, an increasing complexity of collected data and ever higher compliance requirements are putting research and development under increasing pressure to innovate. Digitization is a key transformation that can increase efficiency and gain competitive advantages. Fraunhofer IWS has been working intensively on the development of a research data management system for several years. Experiences in this process, which is primarily designed as a “bottom-up“approach, flow into consulting offers to industry.

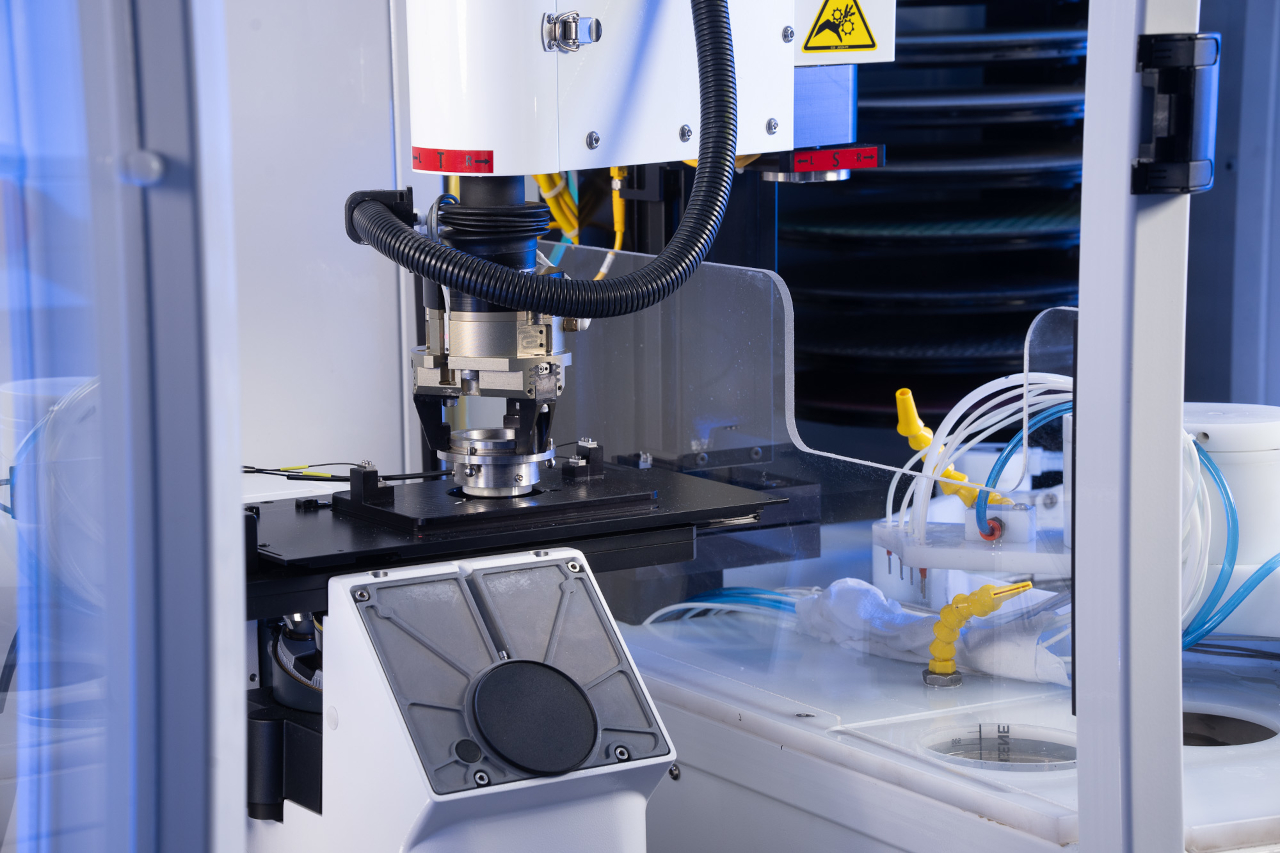

The reuse of experimental findings, which can be realized by means of a suitable research data management concept, becomes particularly clear in the 3D reconstruction of structures (computed tomography) or material structures (by means of metallography robots). Only a stringent recording of all primary and secondary data (including metadata) allows a comprehensive clarification of process-structure-property-effect relationships.

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS