Equipment

- A broad range of short- and ultra-short-pulsed beam sources for various applications in high-precision machining and surface structuring, as well as cleaning applications and fine welding

- 266 / 355 / 532 / 1064 nm

- Pulse durations from 250 fs to 2000 ns

- Output powers up to 300 W

- Pulsed CO₂ and CO lasers for processing surface modifications, cleaning applications, and paper joining (wavelengths 5.5 µm and 10.6 µm, variable pulse duration in the microsecond range, laser power up to 250 W)

Various laser systems and laser modules from established equipment manufacturers as well as in-house developments for a wide range of applications and requirements, including:

- Flexible high-precision processing systems with variable ultrashort-pulse laser, positioning accuracies < 10 µm, and flexible sample handling for processing planar and three-dimensional components

- Laser interference structuring systems and modules (in-house development) with resolution up to 150 nm and processing speeds up to 0.9 m²/min

- CNC four-axis positioning systems (x, y, z, rotation) for processing 3D components, resolution: 0.5 µm, x/y/z scan range up to 500 mm, rotation angle: 360°

- Large-area processing of flat components up to approx. 1.5 × 1.5 m²

- Roll-to-roll (R2R) system for processing web materials

- Roll-to-roll UV/hot embossing system, film width up to 300 mm, up to 50 m/min (TU Dresden)

- Flexible beam shaper for manipulating beam profiles

- High-speed beam deflection system (polygon scanner with up to 800 m/s) for high-throughput surface processing

- Integratable vacuum chamber enables component processing under vacuum or defined process gas atmosphere

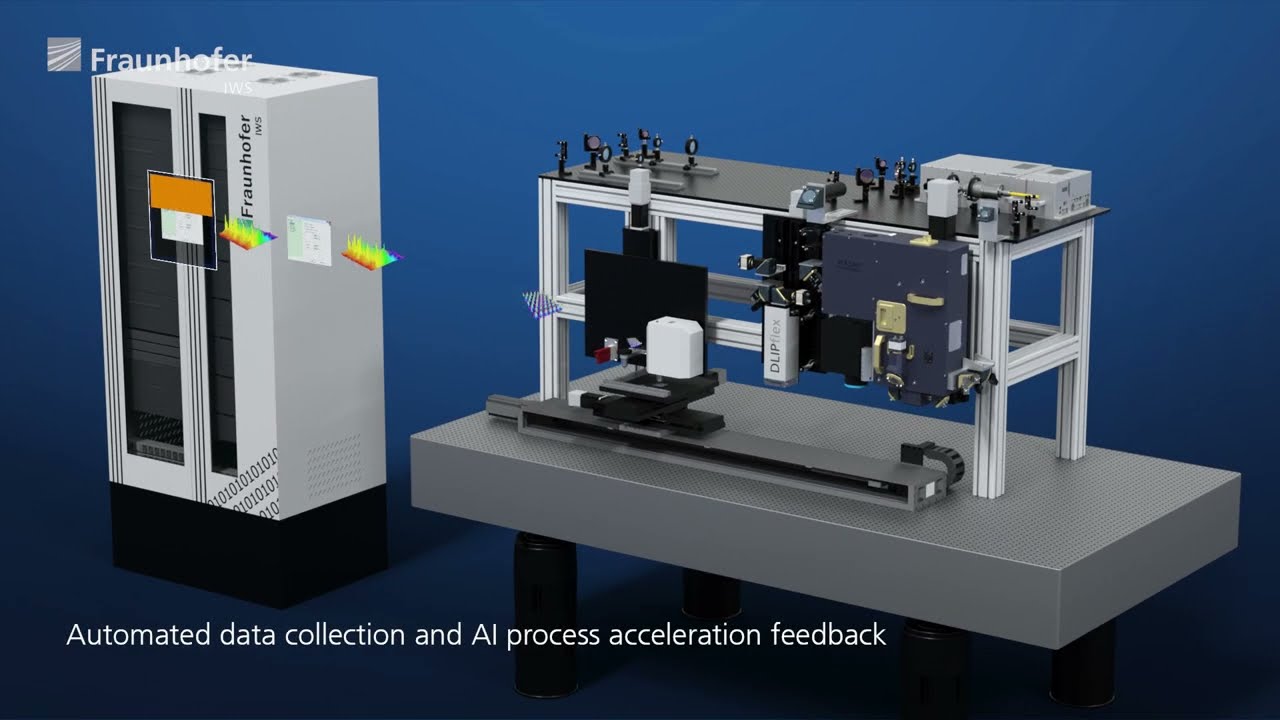

- AI Testbench – predictive modeling for laser precision manufacturing: combination of micromaterial processing with Artificial Intelligence and Machine Learning

AI Testbench – Revolutionizes Laser Manufacturing and Data Acquisition with AI

The AI Testbench is an advanced laser microstructuring test system coupled with an AI-driven learning platform. This combination enables the system to continuously adapt to various operating conditions and predict optimal laser parameters for specific tasks. In addition, the machine is designed for fully automated laser structuring and measurements. It collects process data that can be used to further develop AI algorithms.

Tabbed contents

Application Areas

The AI Testbench is specifically designed for generating large datasets in AI research and for the first time offers the possibility to combine microstructuring and topography measurements in a single machine. It is also ideally suited for the configuration and validation of sensor technologies. The system provides valuable support in diverse application areas:

- Generating large data sets for various materials and microstructuring technologies for AI research

- Verification of on- and offline process measurement systems by fully automated changing of laser parameters and measurement of the resulting surface area

- Optimization of processes for different materials and technologies

Equipment

High performance-USP-Laser – Edgewave FX600

- Pulse duration: 1,6 ps

- Power: 300 W

- Pulse energy: < 3 mJ

- M²: < 1,3

Fiberdirected SP-Laser – Trumpf TruPulse 5020 nano

- Pulse duration: 12 ns – 2000 ns

- Power: 200 W

- Pulse energy: > 5 mJ

- M²: < 5

Technologies

- Pulsar Photonics FlexibleBeamShaper FBS-G3

- Polygon mirror scanner Moeve type PM 100

- Galvo scanner Scanlab IntelliScan 20 + excelliSHIFT

- DLIP – Fraunhofer µScan Nano

Sensor platform

- Topography GBS SmartWLI next

- Glossmeter Zehntner ZGM 1120

- HSI Camera

- Microscopes

Range of Services

- Data for AI: Large-scale data set collection for AI model development

- AI test environment: direct testing and validation of AI algorithms in a real-world environment

- Optimization and Customization: We highlight the potentials and challenges of AI integration in your laser machining processes

Privacy warning

With the click on the play button an external video from www.youtube.com is loaded and started. Your data is possible transferred and stored to third party. Do not start the video if you disagree. Find more about the youtube privacy statement under the following link: https://policies.google.com/privacy© Fraunhofer IWS

- Incident light microscopes, max. magnification: 150x

- Various tribometers, also for testing sliding bearings, force resolution: 0.1 µN

- White light interferometer and confocal microscopes, vertical resolution up to 0.1 nm, lateral resolution up to 140 nm

- Gloss meter, HSI camera

- Acoustic and optical sensors for process monitoring

- Database-based acquisition of process data for generating extensive datasets in AI research

High-speed Camera

- High-speed camera technology with up to 400,000 Hz recording frequency, optionally with microscope optics

- For the clarification of fast running (laser processing) processes,

- Technical data:

- Up to 400,000 images per second

- Magnifications up to the microscope range

- Fading out of disturbing process light by narrow band filters

Privacy warning

With the click on the play button an external video from www.youtube.com is loaded and started. Your data is possible transferred and stored to third party. Do not start the video if you disagree. Find more about the youtube privacy statement under the following link: https://policies.google.com/privacy© Fraunhofer IWS

Thermal Camera

- Thermographic system in the IR spectral range from 7.5 up to 14 µm, with bright, optionally close-up optics

- For clarifying fast processes with heat generation

- Technical data:

- 1024*768 IR pixels – reliable thermal analysis of even the smallest structures

- Up to 0.02 K thermal resolution – noise-free reproduction of the smallest temperature differences

- 30 Hz full image recording frequency, up to 240 Hz with reduced image area

© Fraunhofer IWS

Laser Sources

- Different ns- and ps- pulsed solid state laser systems (available wavelengths: 266, 355, 532 and 1064 nm), 0.5 to 300 W

Equipment Technology

- Laser interference structuring systems (in-house development), resolution up to 150 nm, 0.9 m²/min

- CNC four-axis positioning systems (x, y, z, rotation), resolution: 0.5 µm, x/y/z scan length up to 500 mm, rotation angle: 360°.

- Reflected light microscopes, max. magnification: 150x

- Tribometer, force resolution: 0.1 µN

- White light interferometers and confocal microscopes, vertical resolution: up to 0.1 nm, La-teral resolution: up to 140 nm

- Roll to roll UV/Hot embossing system, film width up to 300 mm, up to 50 m/min (TU Dresden)

- AI Testbench – Predictive modeling for laser precision manufacturing: Combining micromaterial processing with artificial intelligence and machine learning.

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS