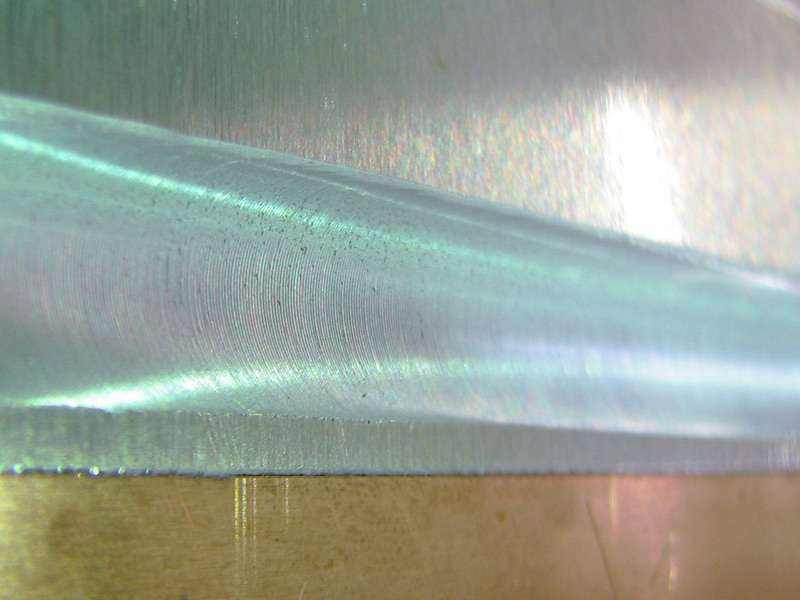

Internal tests showed the possibilities of joining of aluminum and copper parts of various alloys and geometries. Tensile tests of optimized welds demonstrated that breakage generally occurred within the mechanically weaker aluminum.

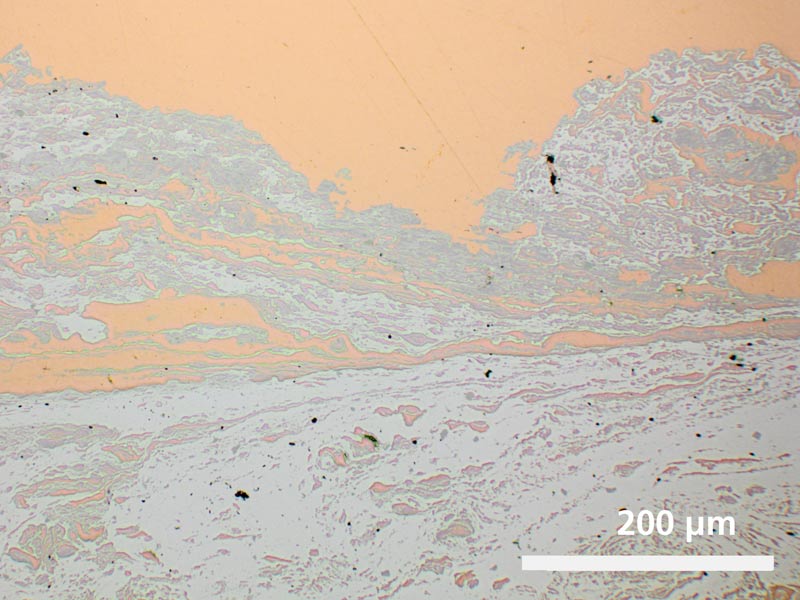

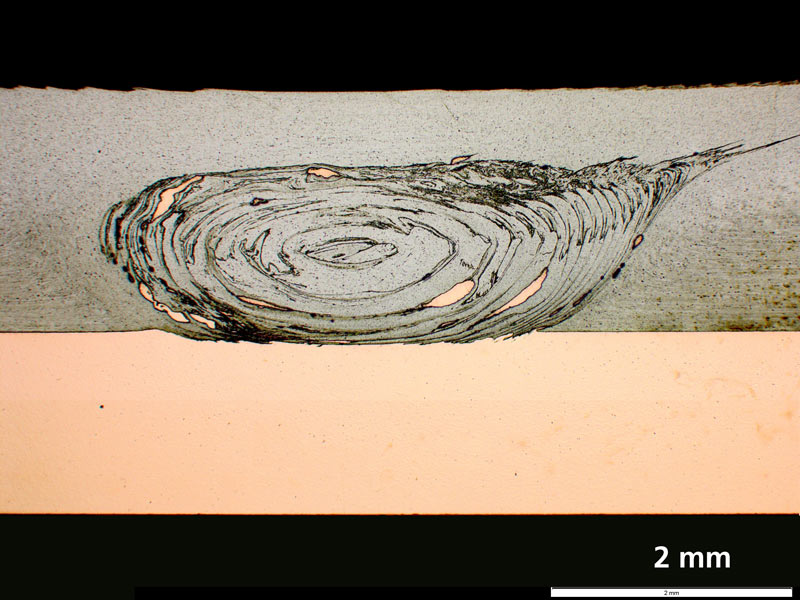

The welding zone is completely different compared other joining processes for dissimilar metals. All melt and solder based processes show a very typical continuous transition zone between the two materials. Friction stir welding does not create such a zone since both materials are simultaneously deformed and kneaded. This is advantageous for properties such as electrical conductivity, which suffers in other processes as a consequence of a low conductive intermetallic interface region.

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS