Ion beam sputtering equipment for nanometer precision coating- and etching processes

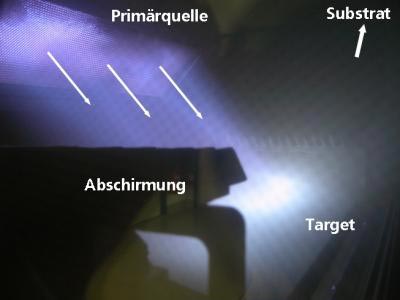

IBSD process in view of the primary ion beam for target sputtering processes

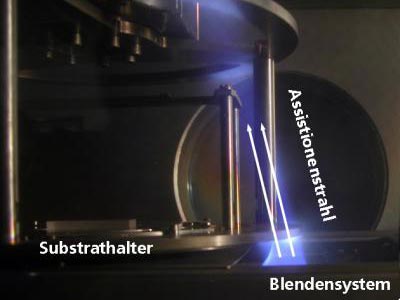

IBSD process in view of the secundary ion beam for substrate treatments (cleaning,smoothing, contouring)

Layer fabrication

- fabrication of focused ion beams in ion sources

- sputtering of the targets by impact processes between the particles of the primary source and the target atoms

- condensation of the sputtered particles on the substrate’s surface

Process conditions

- vacuum: p ~ 2 x 10-8 mbar

- ion sources: primary source for target sputtering processes and a secondary source for film growth modifications (assist operation) or for surface modifications of the substrate (cleaning, smoothing)

- ion source activation: electron cyclotron resonance (ECR)

- number of targets: 6

- target size: 400 mm x 200 mm

- substrate size: load-lock up to a diameter of 200 mm, larger substrates of up to 500 mm have to be operated by hand through the chamber door

Advantages of the IBSD procedure with linear ion sources

- high flexibility for process parameter

- high suitability for reactive sputtering processes

- films with low damage densities

- extremly smooth layers

- simple scalability to larger geometries

- large-area homogenous coatings

Applications

- fabrication of ultra smooth precision layers

- EUV reflection layers on non-perfect smooth substrate surfaces

- multilayer synchrotron optics

- nanometer multilayers for lab X-ray optics

- heat insulation layers (ZrO2, ...)

- XUV reflection layers

- monochromator for X-ray fluorescence analysis

- dieelectric multilayer system with high damage threshold (SiO2/TiO2, SiO2/Al2O3, , ...)

- diamond-like carbon layers (DLC)

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS