In the field of gas analysis our scientists have focuses on the multi gas analysis and the trace gas detection. The evaluation of chemical processes, gas atmospheres and the permeation-, resp. breakthrough behavior of foils and porous materials lead to the identification and to the quantitative analysis of materials and material compounds.

Gas phase characterization

Multi gas analysis

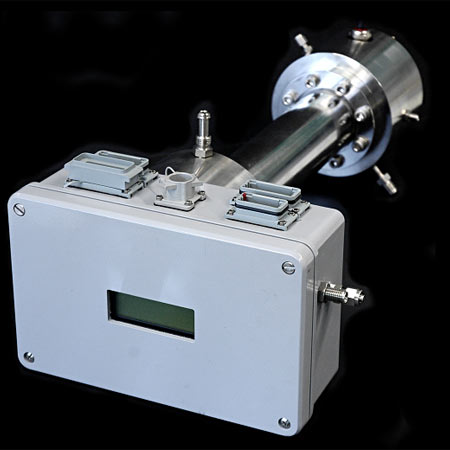

The time-resolved, in-situ detection of different gas species with infra red spectroscopic methods is a well suited, universal characterization device to understand chemical gas phase processes.

The determination of temporal concentrations with detection limits usually in ppm range reveals knowledge about the gas- and exhaust compositions, which emerge during CVD processes. Such processes are, e.g., coating and etching processes in the semi-conducting and photovoltaic industry, sintering processes or the monitoring of gas mixtures.

Trace gas detection

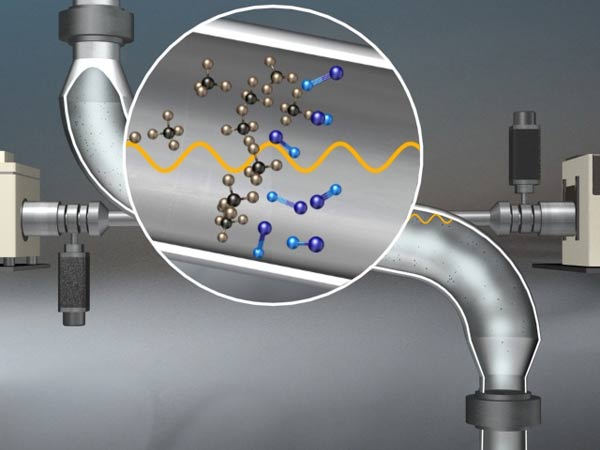

The highly sensitive trace gas detection, basing on laser diode spectroscopy, reveals significant information about the presence of specific gases. Especially, critical species, such as humidity, can be detected as impurities in ultra clean gases with a detection limit within the ppb range.

Combined with custom-tailored optical systems, the laser diode spectroscopy enables the characterization of the permeation behavior, e.g. of foils. These measurements deliver reliable values for the forecasting of service life for, e.g., barrier sealed LEDs. Such a precision could not be realized so far.

Aerosol analytics

The scientists of the group “process monitoring” especially focus their activities on the increased interest, attracted by nano particles. They deal with questions concerning the particulate emission behavior, e.g., laser ablation or chemical coating processes or research on the evaluation of filtered gas atmospheres.

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS