System technology

Focus: Laser multi-pass narrow-gap welding (Laser-MPNGW)

Technical data

- Highly dynamic 2D beam oscillation with frequency of max. 4 kHz

- Laser power: max. 8 kW

- Integrated components:

- Control unit for process control and regulation

- Combined feed of welding filler material and shielding gas

- Sensor technology for weld seam detection

- High-speed camera and sensors for process monitoring and quality assurance

Applications

- Thick sheet range: 10 to 250 mm, e.g. turbine construction (rotor shafts), housing segments

- Structural steelwork, presses, crane and tank installations, shipbuilding

Focus: Highly dynamic beam oscillation

Technical data

- Highly dynamic 2D or 3D beam oscillation with frequencies in the kilohertz range

- Lissajous figures, high dynamic range: 1.5 x 1.5 mm2

- Laser power: max. 5 kW

- Option to implement:

- Sensor technology for weld seam detection

- Sensor technology for process monitoring, e.g. acoustics, image recognition, triangulation

Applications

- Thin sheet range: 0.5 to 5 mm, e.g. aluminum-copper mixed joints, aluminum die casting

- Foil welding, e.g. batteries, electrical contacts

- Aggregates, cooling, air conditioning, heat exchangers, pillow plates, turbocharger shafts

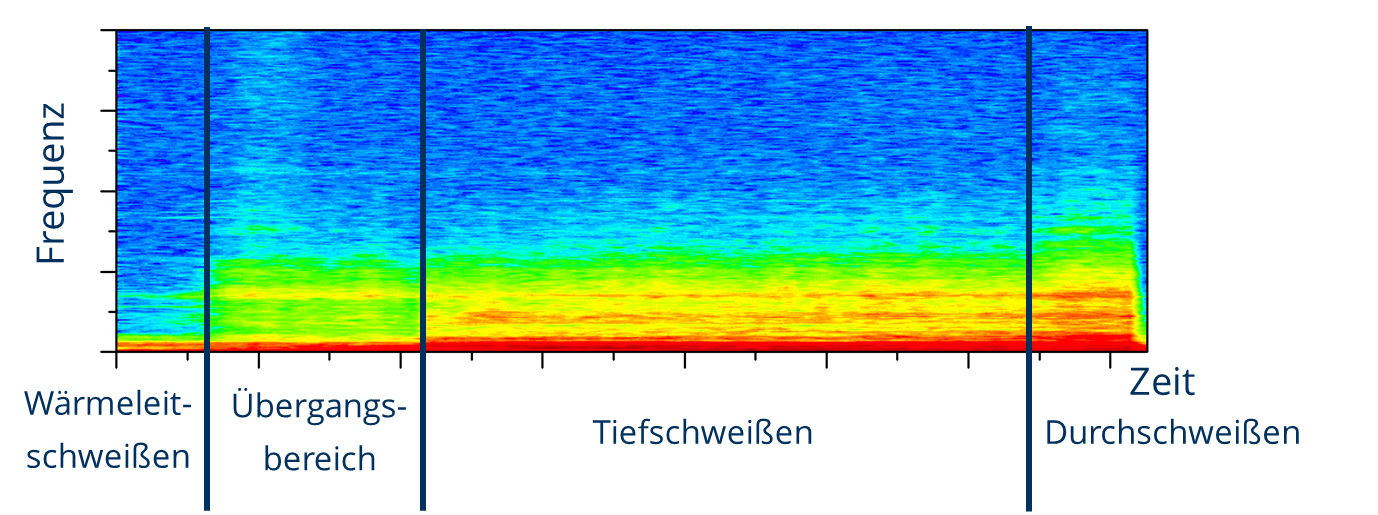

Focus: Acoustic process monitoring

Technical data

- Membrane-free optical microphone

- Low inherent noise

- Frequency range: 10 Hz to 1 MHz (acoustic and ultrasonic)

- Dynamic range: 50-150 dB (A) SPL

Applications

- Wide range of applications from automotive to welded joints in household appliances, aerospace and a variety of measurement tasks to ensure component quality

- Real-time process monitoring of highly dynamic welding processes

- Correlation between weld seam quality and airborne noise possible

- Can be linked to AI evaluation methods

Focus: Geometric topology monitoring

Technical data

- Measuring principle: optical triangulation

- Low reflection sensitivity

- Resolution range: 2.5 to 50 µm

- Repeatability: 0.3 to 0.5 µm

Applications

- Position and distortion measurement of weld contours and welded components

- Inline / offline process monitoring of welding processes

- Correlation between weld quality and external weld appearance (flaking, geometric weld parameters)

- Stand-alone unit can be integrated into new and existing processes

- Combination with other sensors and AI evaluation methods

- Wide range of applications from automotive manufacturing to welded joints of household appliances, aerospace technology and a variety of measurement tasks to ensure component quality

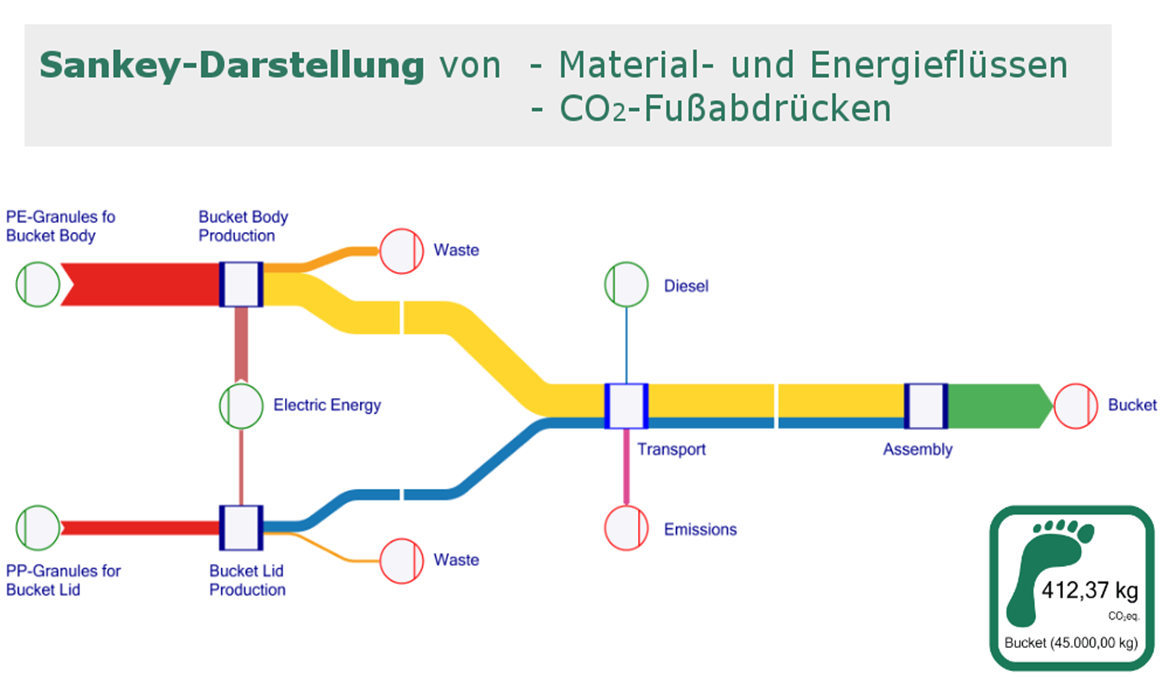

Focus: Evaluation of the CO2 footprint of products and processes

Life Cycle Assessment for the description of material flows using the example of CO2 equivalent – utilization for laser-based manufacturing processes at Fraunhofer IWS.

Technical data

- Conformity of CO2 balancing based on DIN ISO 14064 and DIN ISO 14040

- Generation, calculation and visualization of CO2 and life cycle assessments

- Linking with technical databases, e.g. Gabi

- Generation of Sankey diagrams

Applications

- Assessment of CO2 emissions caused by human production and mobility to achieve European or global climate targets - keyword: max. 1.5°C global warming

- ”Computer Aided Eco-Balancing” (CAEB) for laser-based process chains and products

- Process comparisons for welding processes and production chains

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS