AI-assisted laser material processing using fast compact piezo-driven 3D beam shaping and new laser sources (AI-BEAM)

Dynamic beam modification in combination with multi sensor concepts and artificial intelligence control algorithms allow a paradigm shift in laser macro material processing

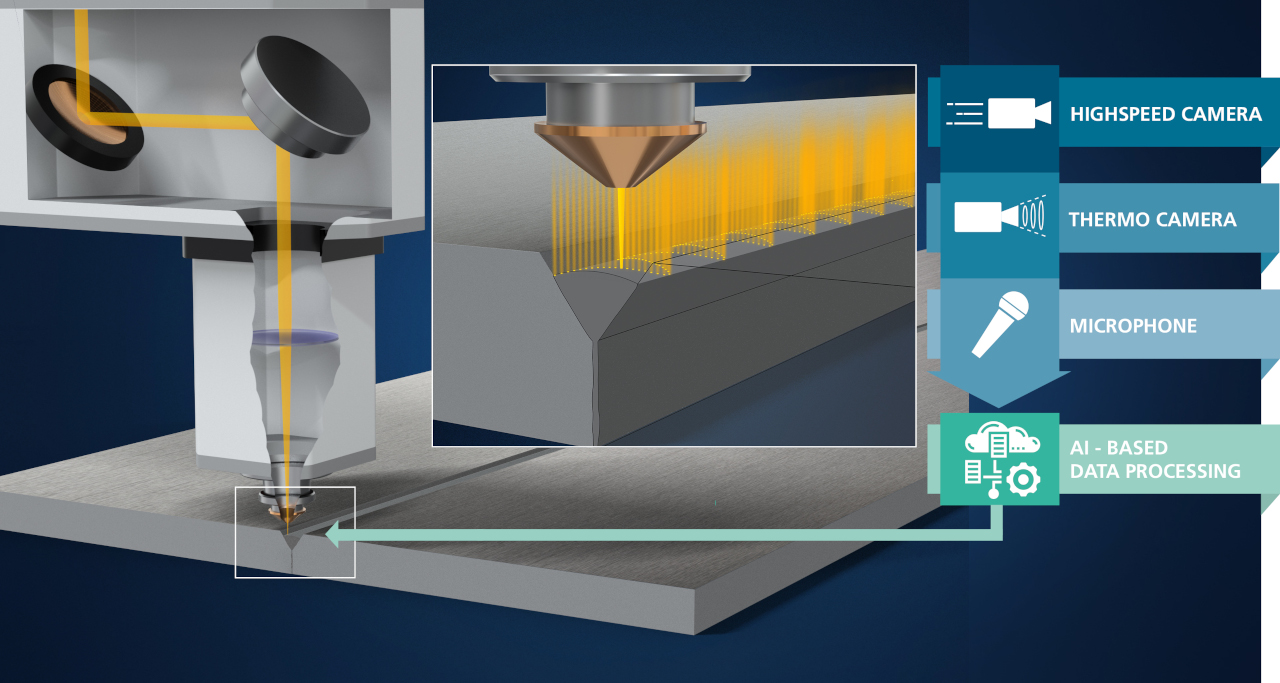

Sensor-supported laser material processing with three-dimensional dynamic beam shaping

In a holistic solution approach, laser source, three-dimensional beam shaping and process sensor technology are coupled for efficient and reliable process control for laser cutting, welding and hardening. The dynamic three-dimensional beam shaping enables a temporal and spatial change of the energy distribution in the range of several kilohertz, whereby this can be adjusted sensor-controlled within a few milliseconds.

The low latency requires an enormous amount of computing power, which is why multi-sensor monitoring of laser processes and AI-based data processing are the subject of current research in order to develop a new generation of inline process control. The long-term goal is to take into account further necessary part and production information in order to develop concepts for cloud-based data-driven services.

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS