Efficient and fuel-flexible internal combustion engines based on innovative materials, layer systems and hybrid designs (FlexHy)

Motivation

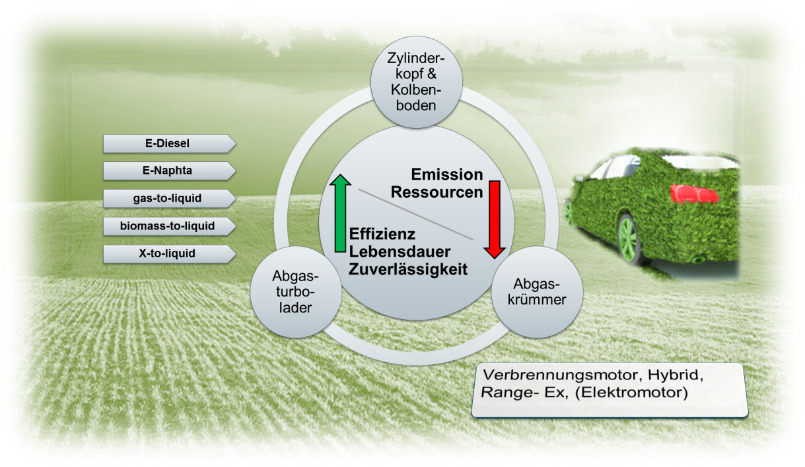

Modern combustion engines are highly complex systems which require a holistic approach for efficiency enhancement. Optimized material and coating systems as well as an adapted material mix allow significant efficiency improvements and emission reductions in cylinder heads (combustion chamber), exhaust gas turbochargers and exhaust manifolds. Alternative synthetic fuels – with or without low proportions of nitrogen compounds and aromatic hydrocarbons – provide the basis for reduced emissions and costs in exhaust gas purification with respect to the targeted higher combustion and exhaust gas temperatures.

Goals and procedure

- A mixed-material joining technology is being developed for a flow- and weight-optimized direct connection of the steel exhaust manifold to the aluminum cylinder head.

- Ceramic protective coatings are being developed for high thermal-corrosive stresses in the cylinder head and piston crown.

- Ceramic Si3N4 lightweight turbocharger turbine wheels, adapted ceramic-metal joining technology and friction optimized laser surface structuring (bearing points of the shafts) are a third module.

Fraunhofer IWS contributes process and material science developments from the technology fields "Joining" and "Thermal Surface Technology". The project consortium consists of the industrial partners Mercedes Benz AG, BorgWarner Turbo Systems GmbH, Rauschert Heinersdorf-Pressig GmbH, FCT Systeme GmbH, GTV Verschleißschutz GmbH and Sitec Industrietechnologie GmbH and Fraunhofer IKTS in Dresden.

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS