Surface pre-processing techniques: Choice, testing, and benchmarking

Pre-processed galvanized sheets by means of blasting in vacuum

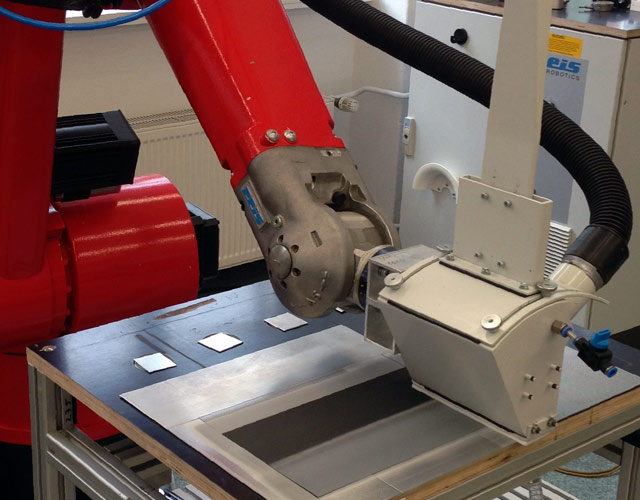

Double rotation nozzles for large area atmospheric pressure plasma processing

Plasma pre-processed thermoplastic fiber composite structures

To produce adhesive bonding joints, sufficient adhesion of the joined partners must be provided. To guarantee adhesion on real parts, surfaces must be pre-treated. In this process, adhesion is improved, and corrosion inhibiting coatings can be produced.

Competences and system technology

Mechanical methods:

- Sandblasting and particle blasting in vacuum

- Coating sandblasting SACO® for silication of joining part surfaces

Chemical methods:

- Flame pyrolysis to apply coupling agent coatings or nanostructured SiOx coatings

- Atmospheric pressure – plasma processing for fine cleaning, activation and separation of coupling agent layers (plasma polymerization)

Laser-based techniques:

- Near-net-surface shape material removal and remelting with pulsed laser beam sources from UV to IR wavelength ranges (laser-micro structuring)

- Generation of periodic structures by means of the DLIP technology

- Large-surface structuring with cw beam sources (laser macro structuring)

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS