Development and optimization of thermally-induced joining processes

Methods for thermally-induced joining, as well as surface pre-processing and bonding technologies, are investigated and refined. These direct joining techniques are characterized above all by short joining times and the substitution of additional material.

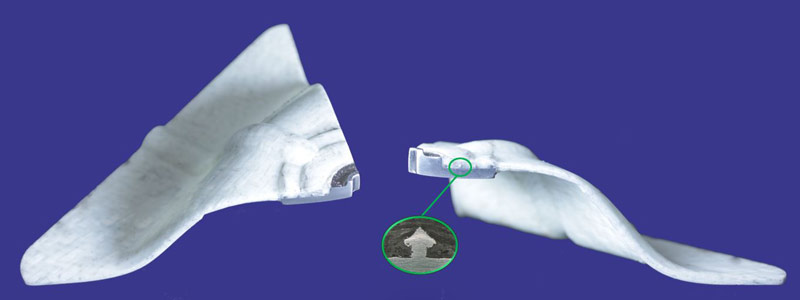

Apart from classical heating elements, highly dynamic ceramic heaters and a wide range of laser systems, as well as induction systems, are available for heating. The use of reactive multilayers is another method to insert local thermal energy quickly. To limit the efficiency of joints like these not only to form fit and weak non-covalent interactions (Van-the-Waals forces), another significant increase in strength can be obtained by the application of adhesion promoter. The direct compound formed this way combines the active principles of form fit and adhesive bonding methods.

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS