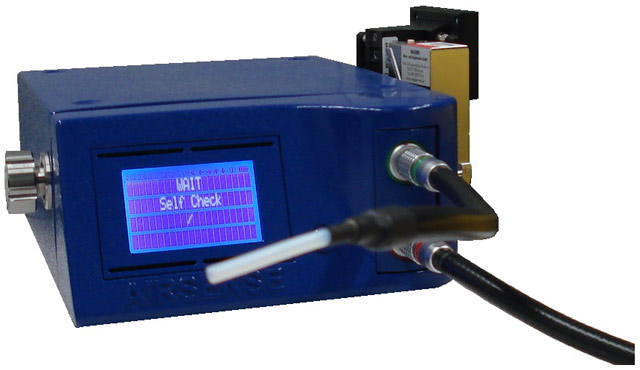

Magnetic suspension balance (Rubotherm)

The magnetic suspension balance enables the samples to be weighed exactly under test gas atmosphere at high pressure and higher temperatures. The adsorption capacity, i. e. the ability of the sample to store gas molecules, can be determined directly from these measured data. This size is a decisive criterion for the assessment of novel materials for gas storage (e. g. methane and hydrogen storage for mobile applications).

The magnetic suspension balance enables the gravimetric measurement of gas and vapor adsorption on samples under high pressure and temperature. The magnetic suspension balance is used to weigh the sample material at a constant temperature but at different pressures or compositions of the gas atmosphere. The adsorption capacity, i. e. the ability of the sample to store gas molecules, can be determined directly from the measured data. This size is a decisive criterion for the assessment of novel materials for gas storage (e. g. methane and hydrogen storage for mobile applications).

- temperature range: 0 °C to 150 °C

- pressure range: Vacuum up to 5 bar

- resolution: 10 µg

- gases: H2, CH4, CO2 and by arrangement

- solid and liquid samples, e. g. catalysts, zeolites, activated carbon, alumina, silica, molten sieves

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS