Motivated by the lightweight principle in mobile applications, the increase in efficiency of thermal processes and the newest electromobility applications increasingly sophisticated welding joints between various materials are emerging. Individualized process solutions for laser welding processes developed by Fraunhofer IWS are applied in numerous industrial products and have significantly contributed particularly in the automotive sector to an increase of the manufacturing efficiency in combination with reduced a price per unit.

In the consolidation of these complex construction, material, process, manufacturing and cost variables to a high quality welding result new potentials arise by the development of high frequency oscillation laser welding. Best examples are filigrane pressure Aluminum die casting components which are to be leak-proof connected with added-on parts. Due to the typically high gas content of these materials such reliable joints cannot be created by conventional laser welding processes. Laser welding with a highly collimated laser and high frequency laser beam oscillation allows for the first time the production of high quality, reliable sealing of pressure die casting components made from aluminum. At the same time the welding energy inserted in the component is strongly limited in order to avoid the deformation of the component.

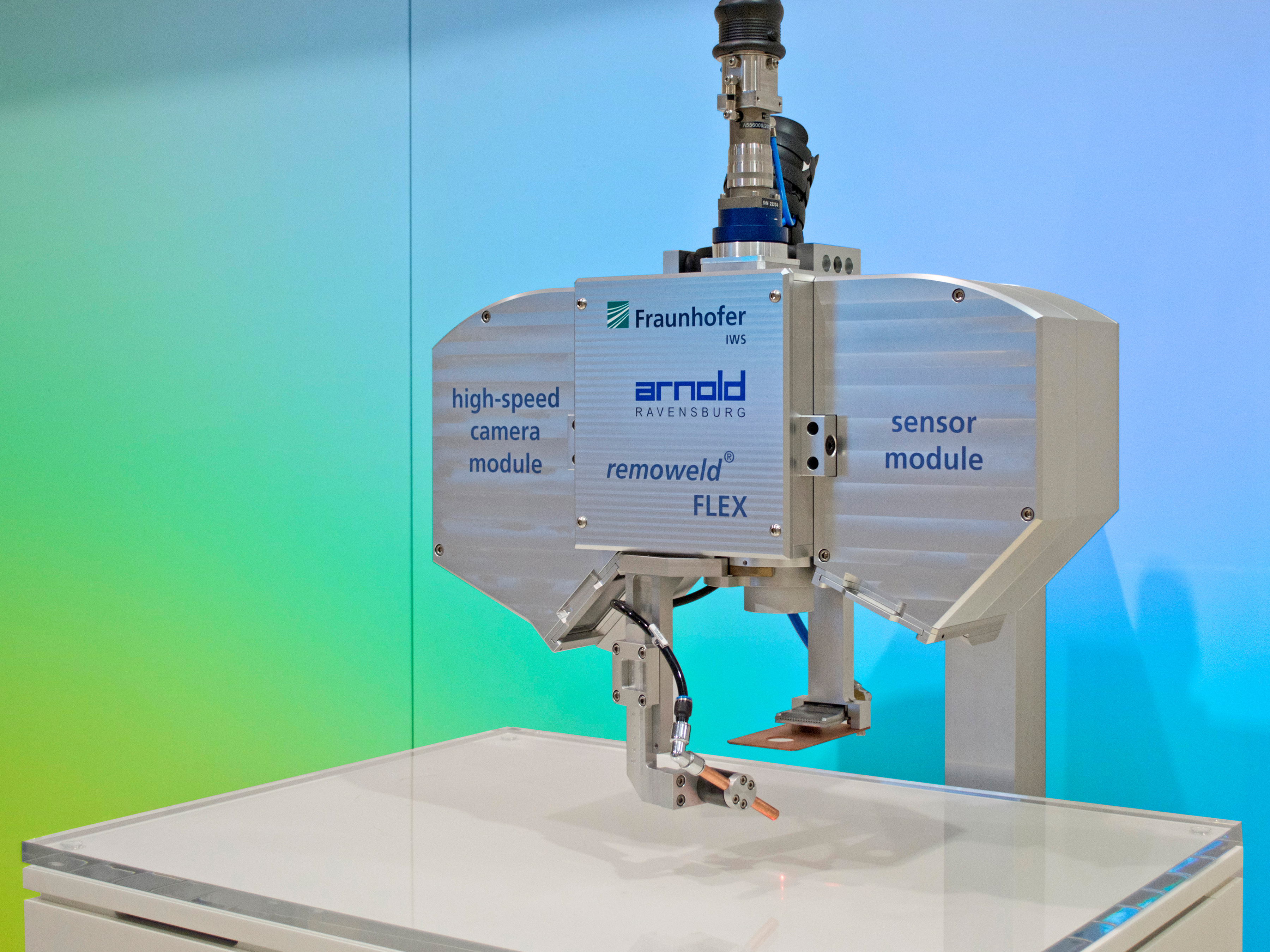

For such kind of applications the IWS researchers have developed a suitable modular welding head comprising as a core component a HF-scanner allowing scan frequencies up to 4 kHz at maximal power of 4 kW. As a preparatory searching unit for the welding seam a contactless sensor module is being used. A subsequent camera-based monitoring module can be used according to the specific application. The modular composition of the welding head flow optionally with or without the sensor or the monitoring module guarantees the flexibility for an individual manufacturing. Fraunhofer IWS offers its customers optionally for the particular manufacturing process the development of a solution with integrated sensors.

The specific construction and installation of the welding head remoweld®FLEX has been implemented together with the company Karl H. Arnold Maschinenfabrik GmbH & Co. KG. The scan manufacturer SCANLAB GmbH supported the development with its know-how.

Together with its partners IWS offers with remoweld®FLEX production-oriented industrial solutions. The process monitoring of all media (cooling media, protecting gases, electrical signals, process data etc.) is being sent via a bus system to a SPS control device for data processing. A clearly structured GUI (graphical user interface) informs the machine operator using a “traffic light” system indicating the process status. It offers in addition the possibility of permanent storage of data for the needs of quality management and can send, according to the principles of Industry 4.0, data about the production advancement to the higher-ranking organization unit for the means of production planning.

The prototype of the new welding head remoweld®FLEX is going to be presented at the joint stand of Fraunhofer-Gesellschaft at the trade fair LASER World of PHOTONICS (hall A2, booth A2.431) in Munich.

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS