Inductive assisted laser roll cladding - Fraunhofer IWS Dresden at the fair "O & S" at Stuttgart from 3 - 5 June 2008

Multifunctional semifinished products, consisting of metallic materials open a new horizon for novel constructive solutions for products with improved characteristics and for reduced production costs. A new solution with regard to process- and system engineering has been developed for the effective production of semifinished products made of hard-to-weld materials combinations - the laser induction roll cladding.

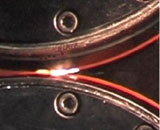

The two bands, to be joined, are heated to a temperature of 40-80% of the melting temperature by a complete inductive heating before they enter the rolling. Simultaneously, the inner parts of the bands, to be jointed, are heated with a linearly shaped laser beam, targeting directly at the roll nip. The heating takes place under a temperature, which lies shortly under melting temperature and an inert gas is used. Thus the deformation in the roll nip is located to the laser heated volumes. This leads to a sufficient deformation of the inner bands which is necessary for a metallic joining.

Under the influence of the roll pressure and no melting condition a smooth, faultless and interface-free microstructure crossover between the two bands is formed. A hardening of the heat-treated steel is avoided. The band, cladded at a speed of 14 m/min, can continuously be cut into parts directly behind the nip. Almost as often as required, it can be deformed and thus directly be proceeded without subsequent heat treatment. Compared to traditional roll cladding procedures, the laser roll cladding, concentrating hitherto to the proceeding of narrow bands, allows a higher variation of the combination of different and thicker band materials. Since the deformation can directly be located to the joining area, a sufficiently deep gearing can be achieved even by an only once rolling.

The efficiency of the laser roll cladding technology is strongly determined by the ability of the laser. Due to the additional inductive band pre-heating the available laser energy can be optimally used and the efficiency can essentially be increased. The procedure is very suitable for the production of semifinished products consisting of combinations of hardenable steel and cheaper or weldable base materials for the production of tools (e.g. driller, saw bands) and parts of the drive engineering (e.g. cams, gears, spindles). Furthermore this technology is especially qualified for the production of semifinished products, consisting of non- or hard-to-weld nonferrous materials combination (e.g. Ti-Al, Ni-Ti, Ni-Al). Additionally a cladding directly on the component's surface can be performed, e.g. for the production of guide ways and wear bands.

The Fraunhofer Institute for Material and Beam Technology IWS Dresden is going to present for the first time some semifinished products, produced with this technology at the fair "O&S - Internationale Fachmesse für Oberflächenbeschichtungen" in Stuttgart from 3 June to 5 June 2008.

Please come and visit us at the "O&S - Internationale Fachmesse für Oberflächenbeschichtungen", Stuttgart (hall 4, booth D79), 3 June 2008 - 5 June 2008.

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS