World record for the reflectance value of EUV lithography mirrors

Within the joint project “EUV-projection optics for 14 nanometer resolution (ETIK)“, funded by the Federal Ministry of Education and Research, Fraunhofer IWS scientists achieved substantial progress in the research of reflection layers for extreme ultraviolet radiation. The extraordinary result is the new world record for the reflectance value and directly implies the increased productivity of EUV lithography systems. In addition, further layer properties could be significantly improved, so that they now enable the application of EUV mirrors for higher numerical aperture at simultaneously lower scattered radiation.

The introduction of the EUV lithography associates a fundamentally new technical approach for the exposure of semiconducting structures. Due to the fact that there are no transparent materials for EUV radiation available, the application of lenses for beam formation is excluded. The optical system has to be completely designed with mirrors. The reflection layer deposited on the mirror carrier has to meet extreme demands with respect to accuracy, stability and reproducibility. These demands require high-precision processes, which enable the fabrication of nanometer layers with picometer precision.

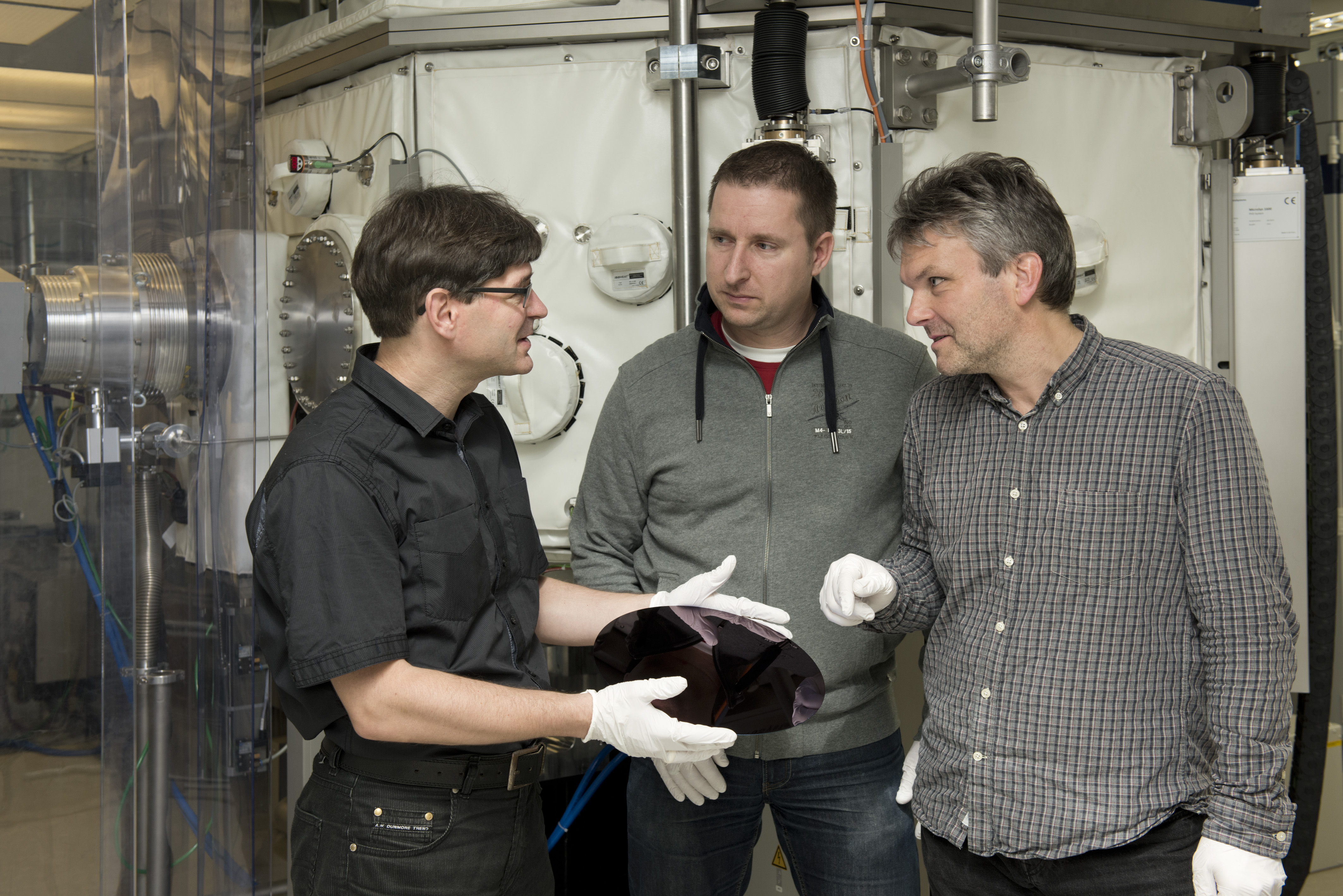

Within the framework of the project, headed by the consortium leadership of Carl Zeiss SMT, in cooperation with a further 5 project partners, the IWS scientists focused their research on reflection layers for EUV lithography mirrors, which now show considerable improvements compared with the state-of-the art at the beginning of the project. Firstly, the roughness in the high-frequency spectral range was reduced by a factor 2. This process enables the fabrication of mirrors with reduced stray light and with improved usable intensity. Due of the fact that in a EUV objective numerous mirrors have to be combined the reflectance increase of one mirror to 70.75 % results in a significant reduction of the exposure time per wafer in the lithography tools.

The newly available (April 2014) IWS coating device for Magnetron-Sputter-Deposition processes decisively facilitated these excellent results. This new device is considerably more flexible with respect to process parameters, materials and processible mirror sizes. Thus, it successfully facilitates further important aspects of layer developments such as process developments for the production of broadband coatings as well as the consideration of new materials in multilayer designs. With respect to coating technologies important preconditions could be created for the industrial application of this technology for the fabrication of low-loss EUV systems with high numerical aperture.

The project was funded by the Federal Ministry of Education and Research (project number 13N12260).

Latest testing results will be presented at the 11th Nanofair, being held June 14 - 16, 2016, at the International Congress Center Dresden. The congress with its accompanying exhibition offers a unique platform for national and international experts, coming from industry and science. Please find further information about the congress and registration at www.nanofair.com.

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS