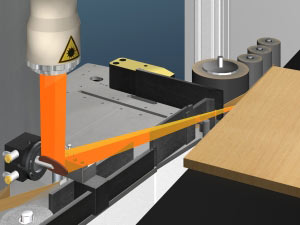

Laser-supported joining techniques for edge bonding of furniture panel boards

Task

Adhesive deposition on narrow surfaces is a major part of mechanical furniture fabrication. Equipment for this operation is used in industry and in handicrafts, where it is part of the standard machinery. Melt adhesives are primarily in use; they are applied as hot melts to the narrow panel surface or the coating material by means of a roller, and bonding subsequently occurs.

Melting of the adhesives, however, is energy-intensive and a long procedure. Furthermore, due to the direct contact of the applicator roll with the panel material - mainly in the case of chipboards - contamination may appear that hinder the adhesive application. For this reason, we sought an alternative solution suitable for automation.

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS