Metal surfaces with organophilic structures for reproducible and long-life bonded joints

Task

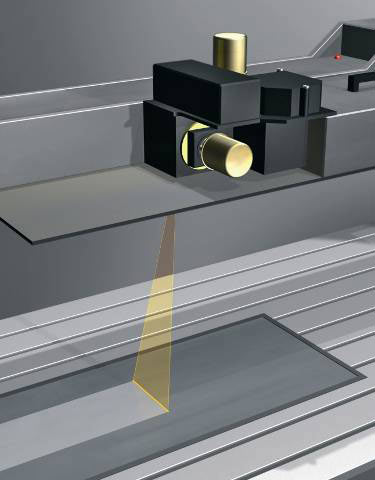

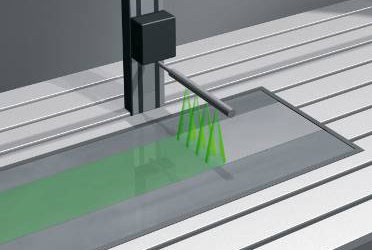

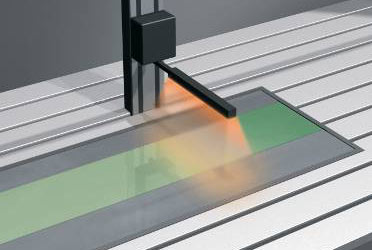

Aluminum materials and other metals with an anodic oxide outer film, need anticorrosive and inhibiting oxide layers of sufficient thickness and density. In addition to the chemical oxidation processes, selective and ecological alternative methods have to be developed for industry. For this purpose, thermal oxidation was produced by laser beam.

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS