10th International Summer School "Trends and new developments in Laser Technology"

August 23–26, 2021, Online Workshop

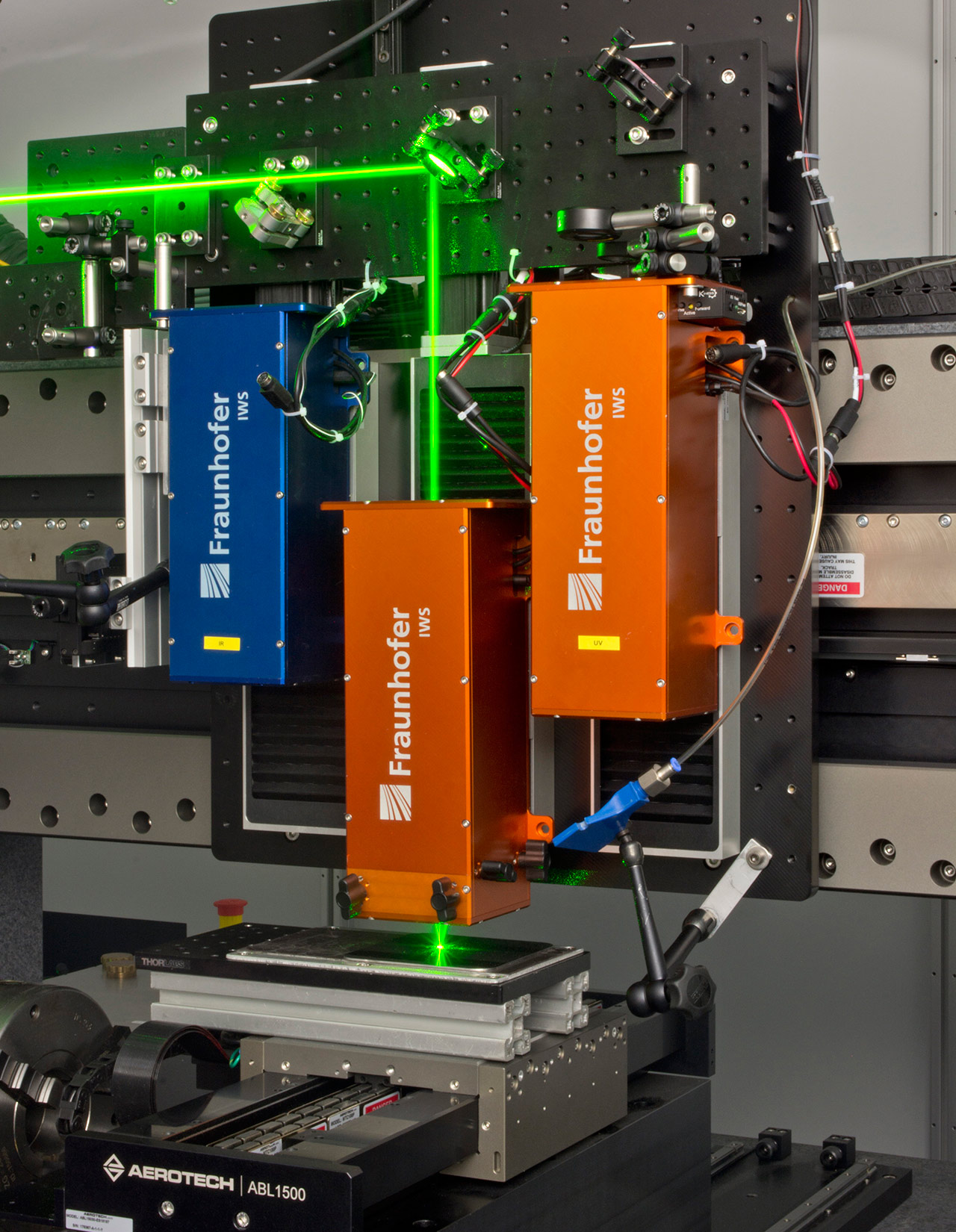

The Technische Universität Dresden and the Fraunhofer Institute for Material and Beam Technology (IWS) are organizing the tenth International Summer School “Trends and new developments in Laser Technology“ from 23 to 26 August 2021. This four days workshop aims to bring together undergraduate and PhD students in an intensive study program on fundamental and applied aspects of laser technology.

The Summer School program consists of lectures by renowned experts and informal discussion sessions, as well as practical insights. The program also offers participants the opportunity to present their own research topics and aims to facilitate the exchange of new ideas in these areas.

Topics

- Surface hardening technologies

- High speed 2D laser cutting

- Laser welding

- Additive manufacturing processes

- Applications of ultra short pulsed lasers

- Laser process simulation

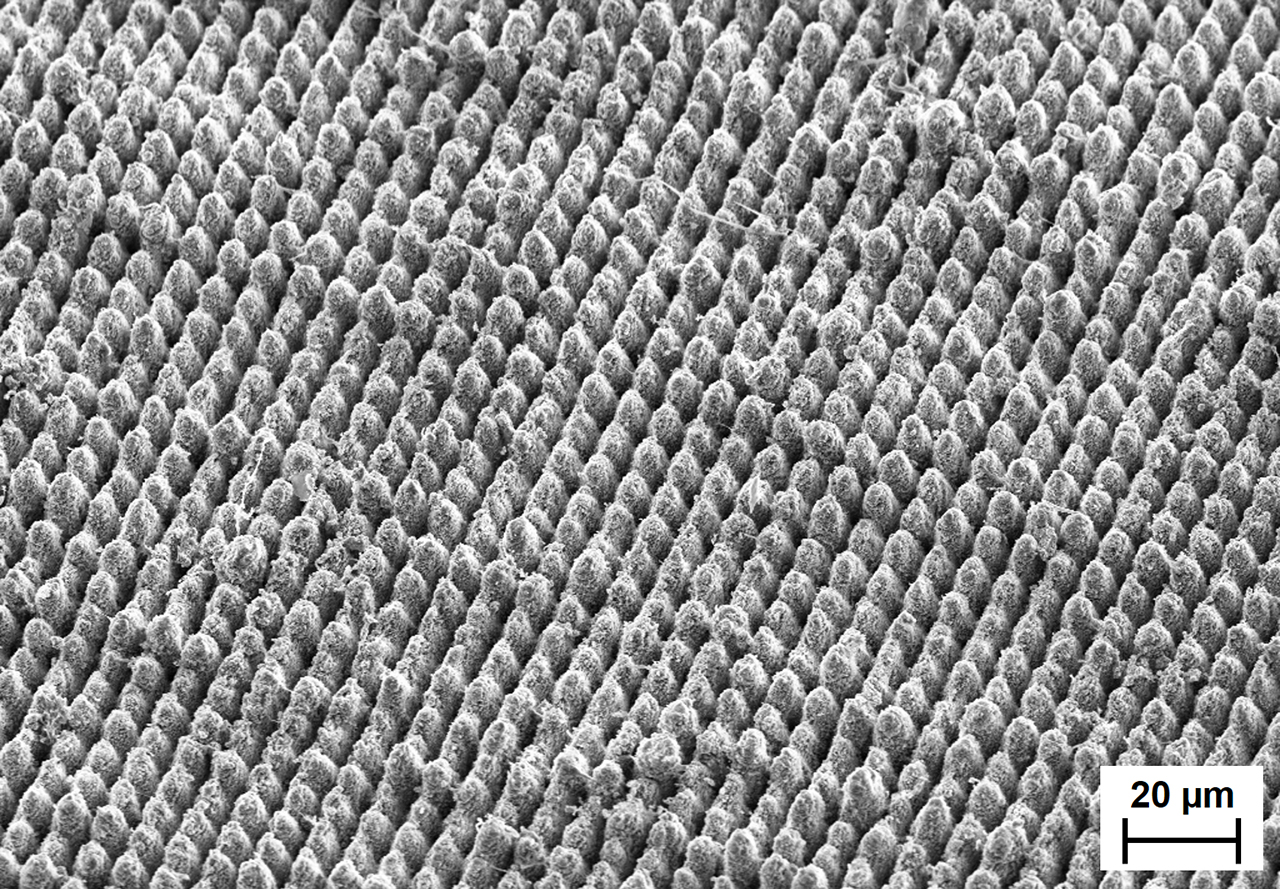

- Laser micro/nano structuring

- Laser interference patterning

The programme will include:

- Participant presentations (15 minutes)

- Proceeding book with extended abstracts

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS