In material and technology development, it was possible to show that a fully polymeric monolithic dielectric actuator can provide promising results. The material parameters of the individual coatings could be set and adjusted deliberately and reproducibly. The manufacturing technology engineered is suitable for widely differing geometric systems; it can also be employed to fabricate thin coatings. These polymer coatings are thicker than those achieved by sputtering, on the one hand. On the other hand, if the mechanical properties are adjusted, then the influence of the coating thickness can be reduced significantly. In the lab test, coating thickness values of about 20 µm were achieved, and these values can be reduced much more by technological optimization.

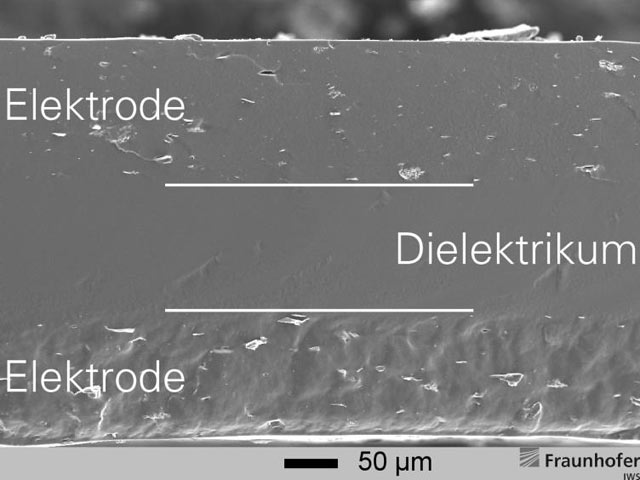

The fully polymeric dielectric elastomer actuators provided outstanding results in their role as an actuator. The IWS team was able to show that a decrease in both the coating thickness and the Young’s modulus of the dielectric coating positively affects the performance as an actuator, and thus, confirms the theoretical fundamentals of the dielectric elastomer actuators. The dielectric elastomer actuators produced are also characterized by a very low defect density (Figure 2), so that the layer structures are characterized by “high reliability” of more than 1 million cycles without optical or function-relevant impacts.

The “CANDELA“ research project was performed within the scope of the BMBF (Federal Ministry for Research and Technology) under the registration code 13 N 10660.

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS