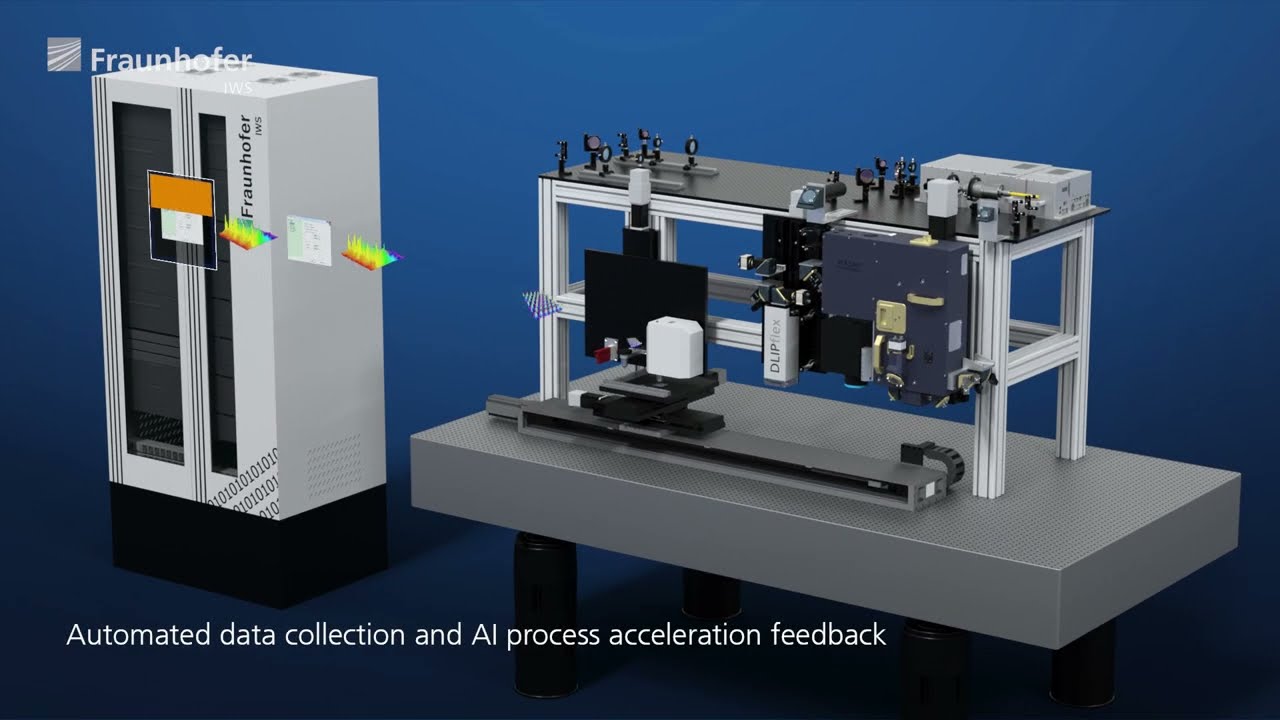

Revolutionizing Laser Manufacturing and Data Acquisition with AI

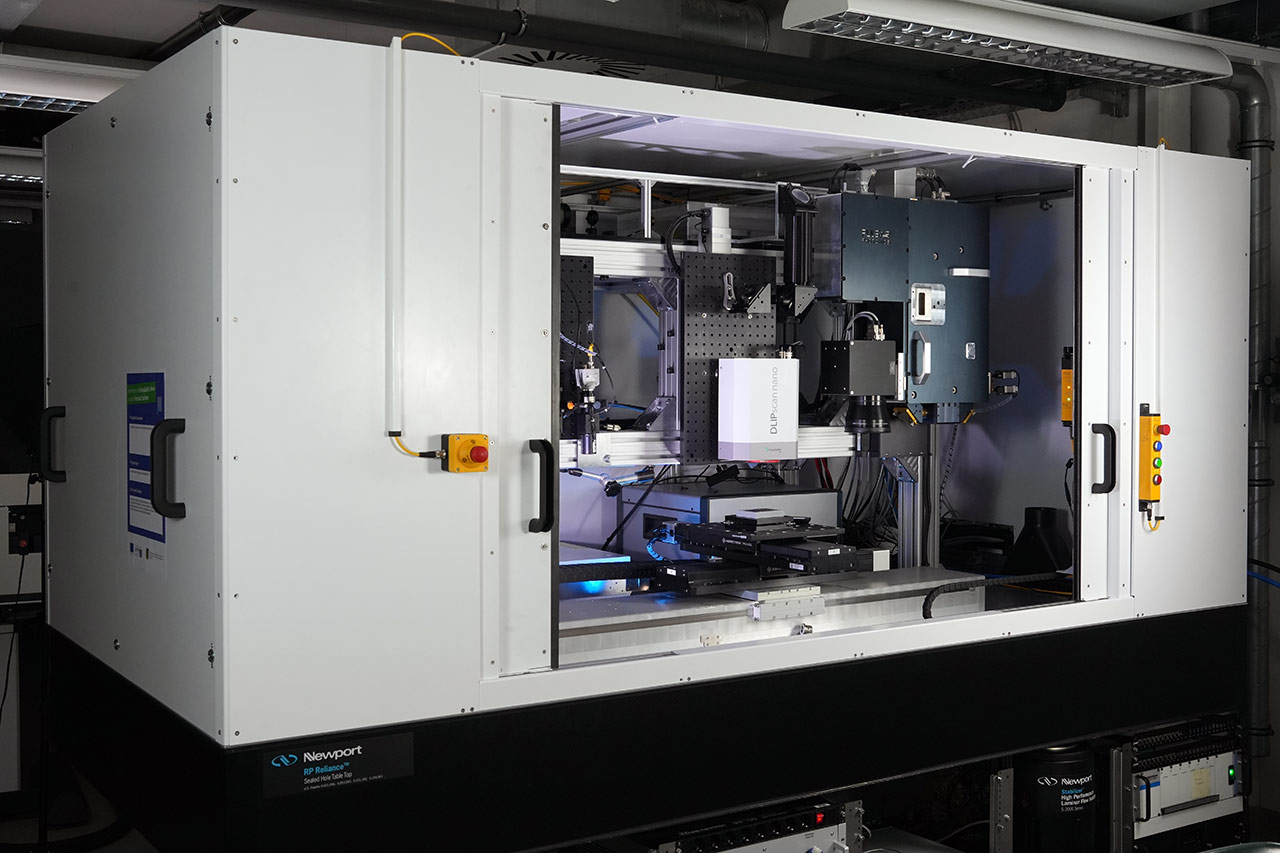

The AI Testbench is an advanced laser microstructuring test facility coupled with an AI-driven learning platform. This combination enables the equipment to continuously adapt to different operating conditions and predict optimal laser parameters for specific tasks. In addition, the machine is designed for fully automated laser structuring and measurements. It collects process data that can then be used to further develop AI algorithms.

Application Area

The AI Testbench is specifically designed for generating large datasets in AI research and for the first time offers the possibility to combine microstructuring and topography measurements in a single machine. It is also ideally suited for the configuration and validation of sensor technologies. The system provides valuable support in diverse application areas:

- Generating large data sets for various materials and microstructuring technologies for AI research

- Verification of on- and offline process measurement systems by fully automated changing of laser parameters and measurement of the resulting surface area

- Optimization of processes for different materials and technologies

AI Testbench – AI Algorithms for Laser Surface Structuring

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS