Service Offers

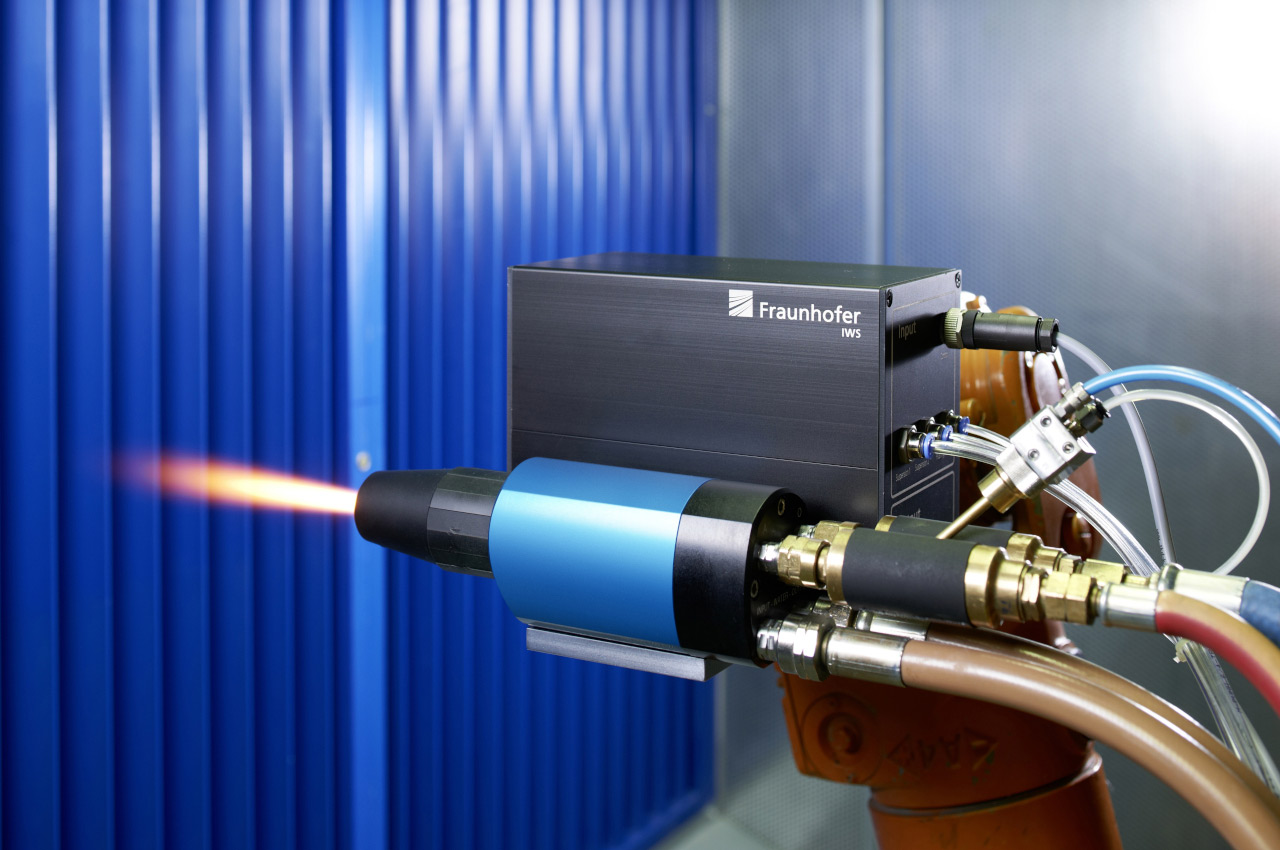

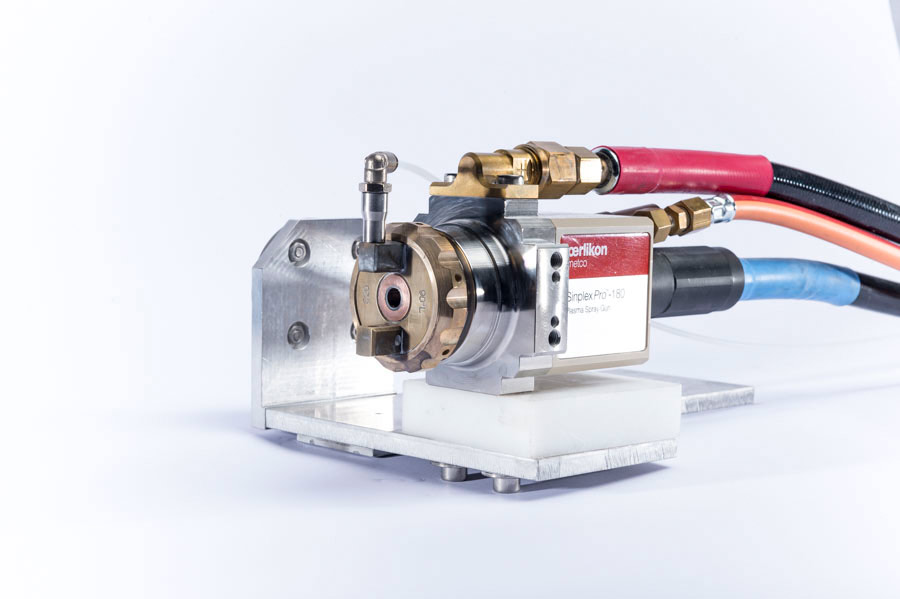

The Fraunhofer IWS offers a wide range of advanced thermal coating technologies for functionalizing components made of various materials such as metals, lightweight metals, plastics, and ceramics. The coatings are applied without thermally affecting the components. The available processes include atmospheric plasma spraying (APS) with F6 and SinplexPro spray guns, high-velocity oxy-fuel spraying (HVOF) with K2, TopGun, and DJ2700 spray guns, as well as arc wire spraying (LDS) with an Arc-Spray-Jet-One/2nd Gen spray gun.

In close collaboration with national and international partners, the IWS provides a broad spectrum of services, including:

- Holistic consideration of the process chain as a customer-specific system solution, from material selection to the application of the coated component.

- Development of tailored coating systems that meet specific requirements and enhance the performance and added value of the components.

- Manufacturing of system-technical components for thermal spraying, particularly with suspensions and solutions.

- Support in the transfer and integration of coating technologies into existing systems or new production lines.

- Consultation, training, and support for users in the implementation of new technologies such as suspension spraying.

Core Competencies

The core competencies of the IWS lie in the development of innovative coating solutions, including electrical layer heating elements, thermal barrier coatings for hydrogen turbines, sustainable hardmetal coatings for highly stressed components, protective and functional coatings for lightweight components (FRPs and MMCs), as well as coatings for electrodes and separators in hydrogen production (for PEM and AEL). In the field of thermal spraying with suspensions and solutions, the IWS offers system engineering solutions such as the 3DSF feeder and injectors for APS and HVOF processes. Furthermore, there is a focus on non-destructive characterization of coatings, including analysis with laser-acoustic surface waves (LaWave) in collaboration with our IWS colleagues.

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS