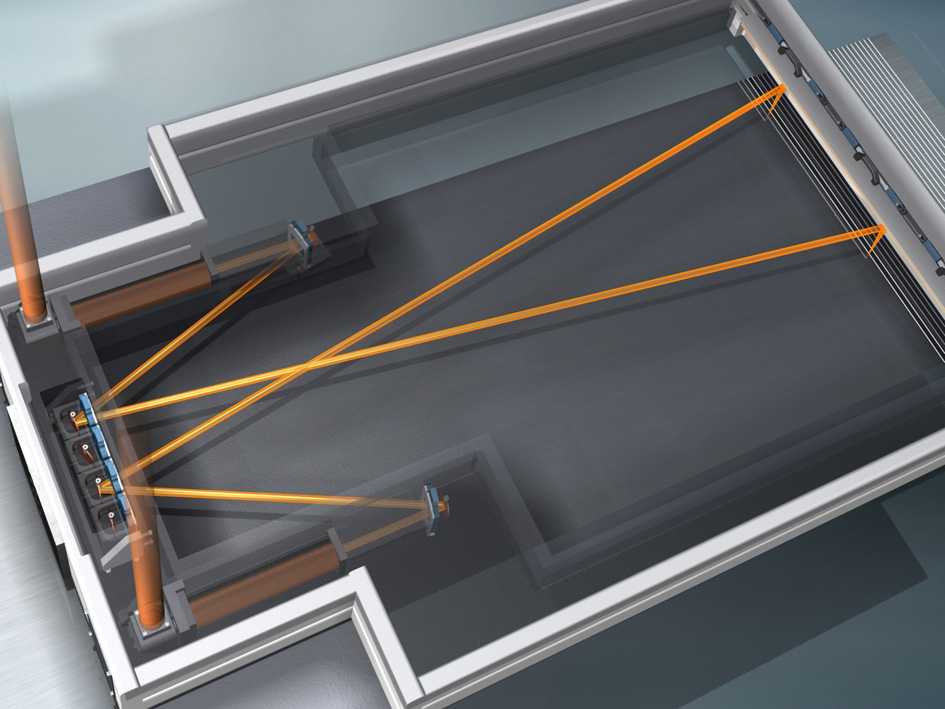

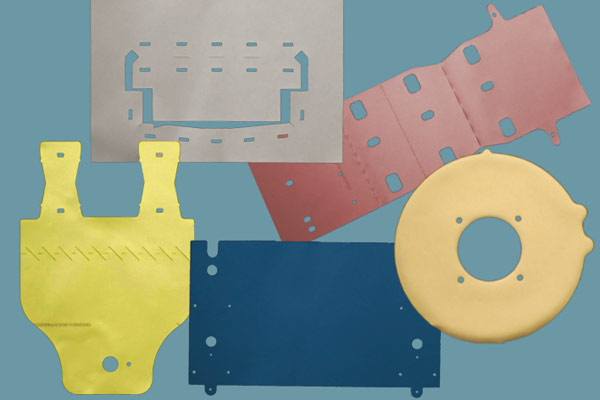

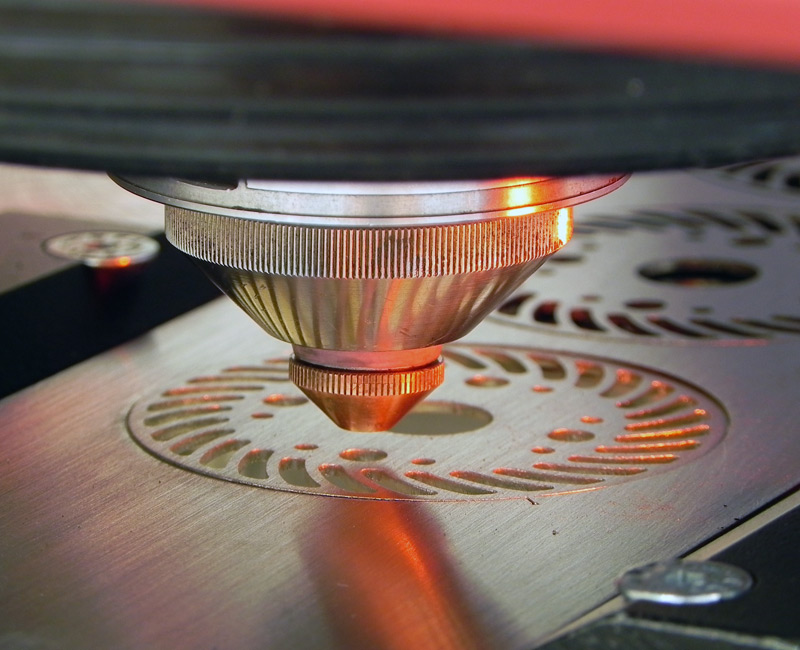

For the industrial use of remote technology for welding, cutting, ablation and perforation, Fraunhofer IWS Dresden develops software and control solutions that take into account the process and customer requirements.

Depending on the application, the control technology solutions available on the market are examined and, if necessary, own solutions are developed. The focus is on the highly dynamic control of galvanometer scanners and their integration into new or existing machines.

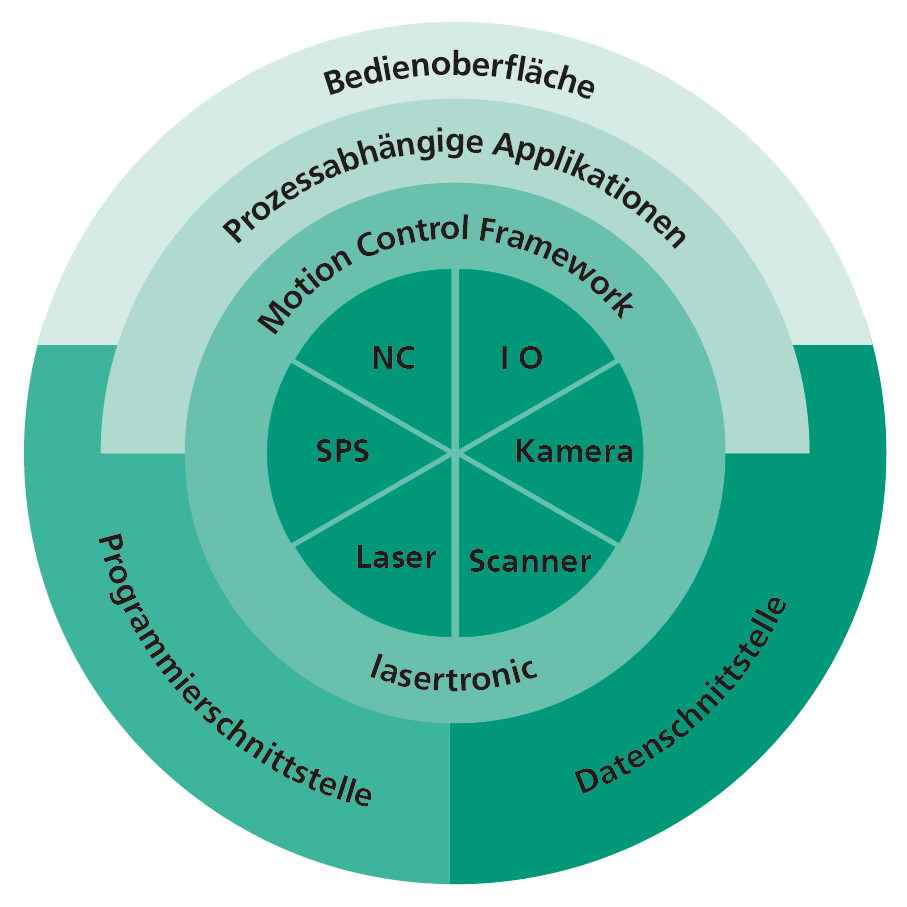

Motion Control Framework

The motion control framework forms the basis for efficient, yet adaptable software development for the realization of complex remote processing tasks. The goal of software development based on the motion control framework is to efficiently encapsulate the technological and process interrelationships so that an easy-to-use software is created for the end user. The Fraunhofer IWS does not only act as a pure software developer here, but also contributes its longstanding process competencies in the field of laser material processing to develop a user-friendly control technology solution.

ESL2-100 Module

The ESL2-100 module was developed by Fraunhofer IWS as a gateway between the EhterCAT fieldbus and the SL2-100 protocol. In the context of control system development the ESL2-100 module is used if

- a networking of the galvanometer scanners to a superior machine control (PLC) is necessary or

- a real-time capable influence of the scan movement has to be realized.

Since all sensors and actuators involved in the processing task can be combined in one controller, continuous, real-time and synchronous communication is possible. Due to the flexibility of the fieldbus system, the galvanometer scanners involved can be distributed and scaled almost arbitrarily.

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS