For coating and technology development as well as sample and small series coating, systems for arc coating (classic dc-Arc, puls-Arc), electron beam evaporation, sputter coating and hybrid coating processes are available. These systems can be used to perform a wide range of different coating tasks.

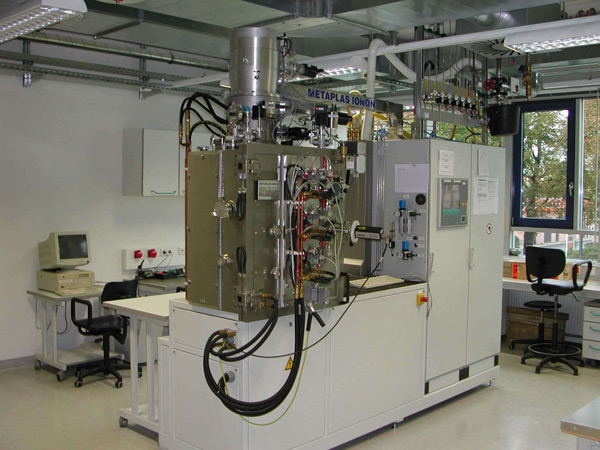

PVD Technologies and Equipment

Technical Data

- Usable chamber volume: Ø 450 mm x 500 mm

- Three evaporators for Arc PVD coating (coating with highly ionized plasma),

- Plasma pretreatment device

Applications

- Deposition of metals, various metal compounds (nitrides, oxides, carbonitrides, nanocomposites) for R&D purposes, experimental small series etc.

- Process and coating development for the realization of customer-specific coating solutions

Technical Data

- Usable chamber volume: 400 mm x 400 mmm x 400 mm

- Two evaporators for Arc PVD coating (coating with highly ionized plasma)

- Sputter coating source (coating with low ionized plasma)

- Plasma pretreatment device

Applications

- Deposition of metals, various metal compounds (nitrides, oxides, carbonitrides, nanocomposites) for R&D purposes, deposition of particularly thick PVD layers (>100 µm)

- Development of coating sources (e.g. magnetically controlled arc sources)

- Process development for the deposition of innovative coating materials

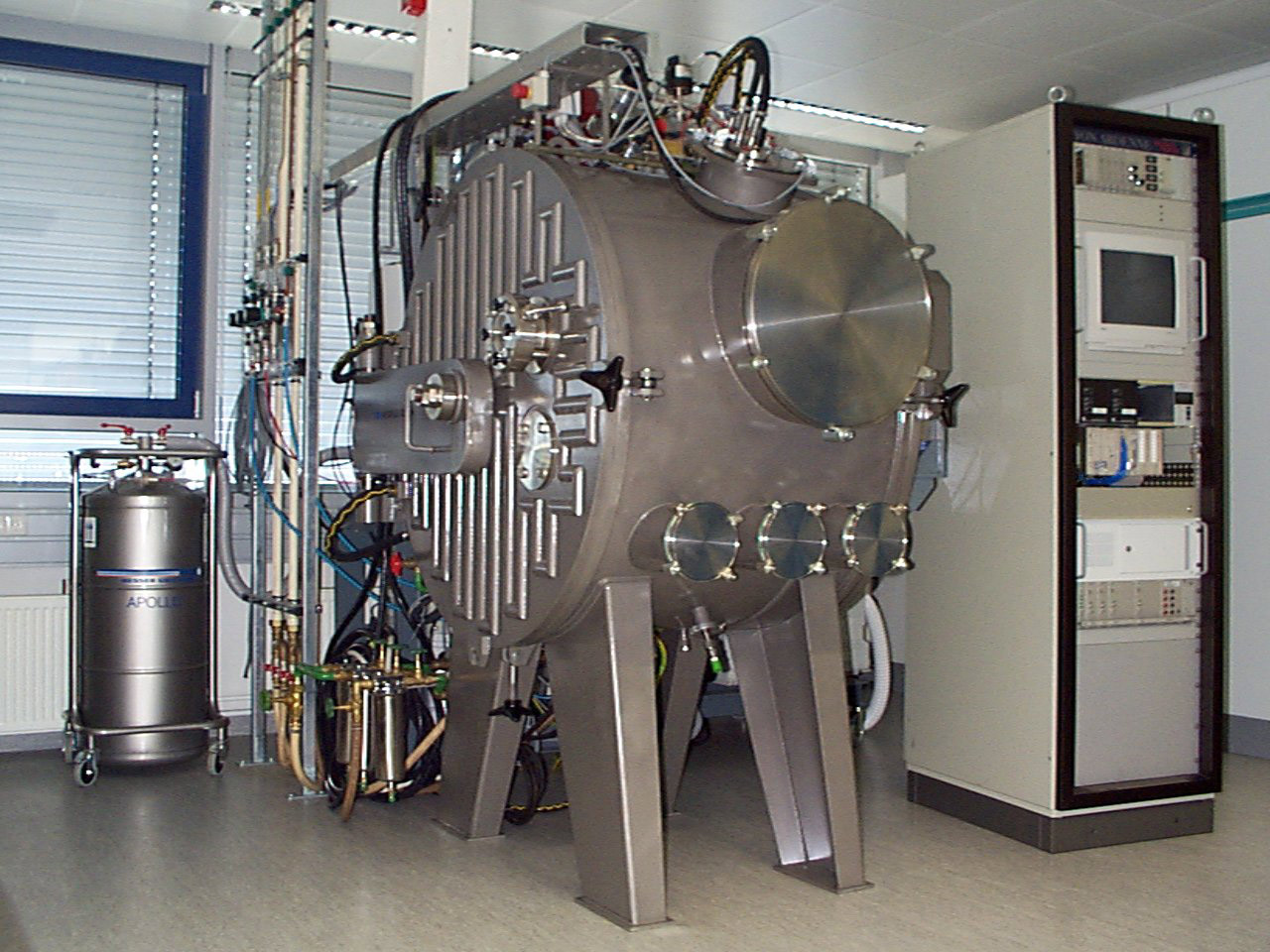

Combination coating system OLGA for research into hybrid PVD processes (e.g. electron beam + vacuum arc) for high-rate deposition of a wide variety of coating materials.

Technical Data

- Usable chamber volume: Ø 1200 mm x 900 mm

- Electron beam gun (40 kW) for vapor deposition (Coating with thermal vapor)

- Two evaporators for Arc PVD coating (Coating with highly ionized plasma) and for combination with the vapor deposition process

- Plasma pretreatment device

Applications

- Deposition of metals and many other materials at high rates for R&D purposes, Deposition of particularly thick PVD layers (> 1 mm)

- Development of combination processes (vapor deposition process +X)

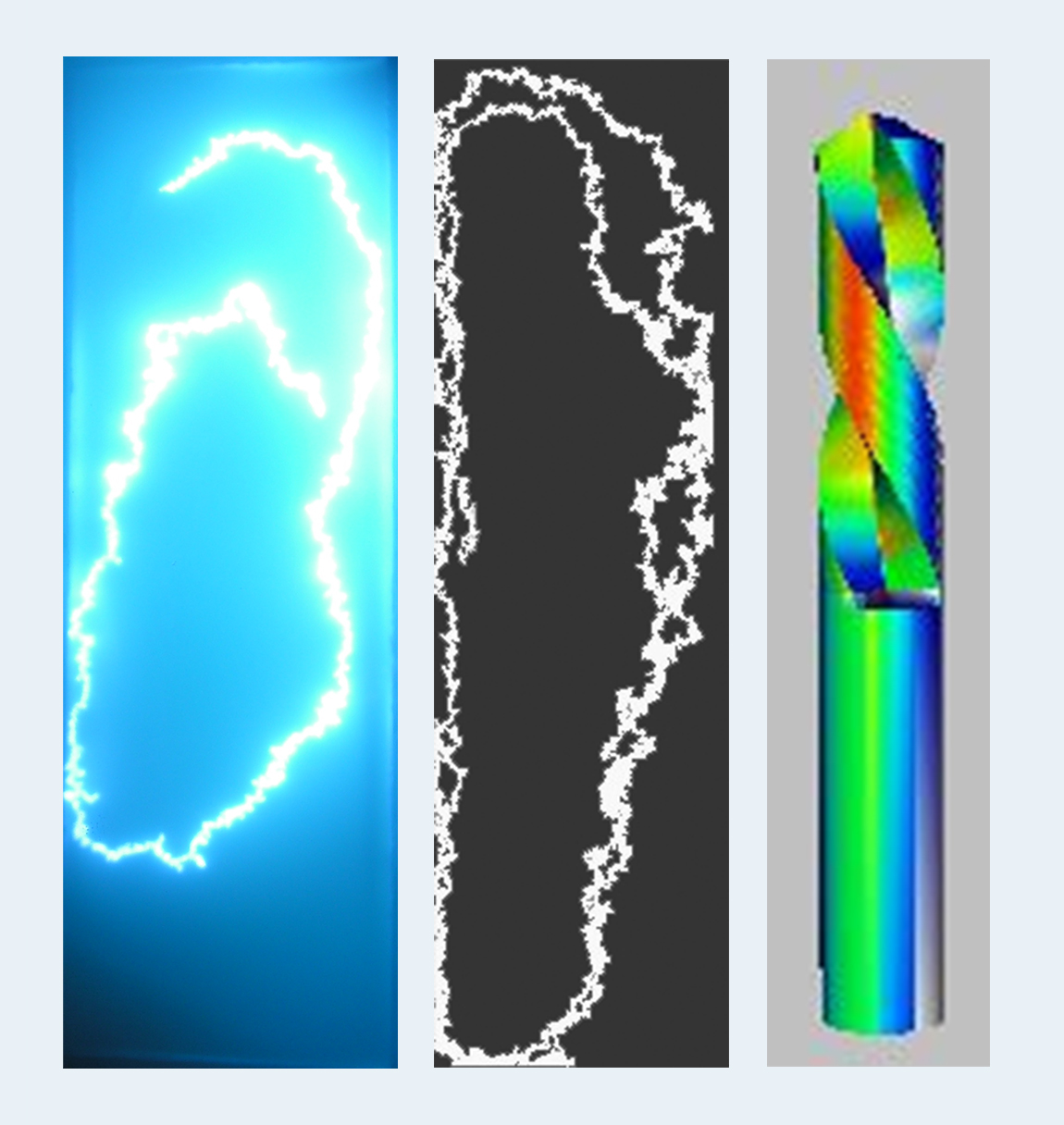

Simulation Tools for Modeling

- Of cathode processes during arc evaporation

- Of the plasma propagation in the coating chamber

- Of layer thickness distribution on real component geometries

The tools are under development and some of them are already available for modeling tasks.

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS