Battery and hydrogen-powered electric vehicles are an important factor in the climate-friendly electromobility of the future. In particular, in combination with renewable electricity, they produce significantly less CO2 than conventional combustion engines.

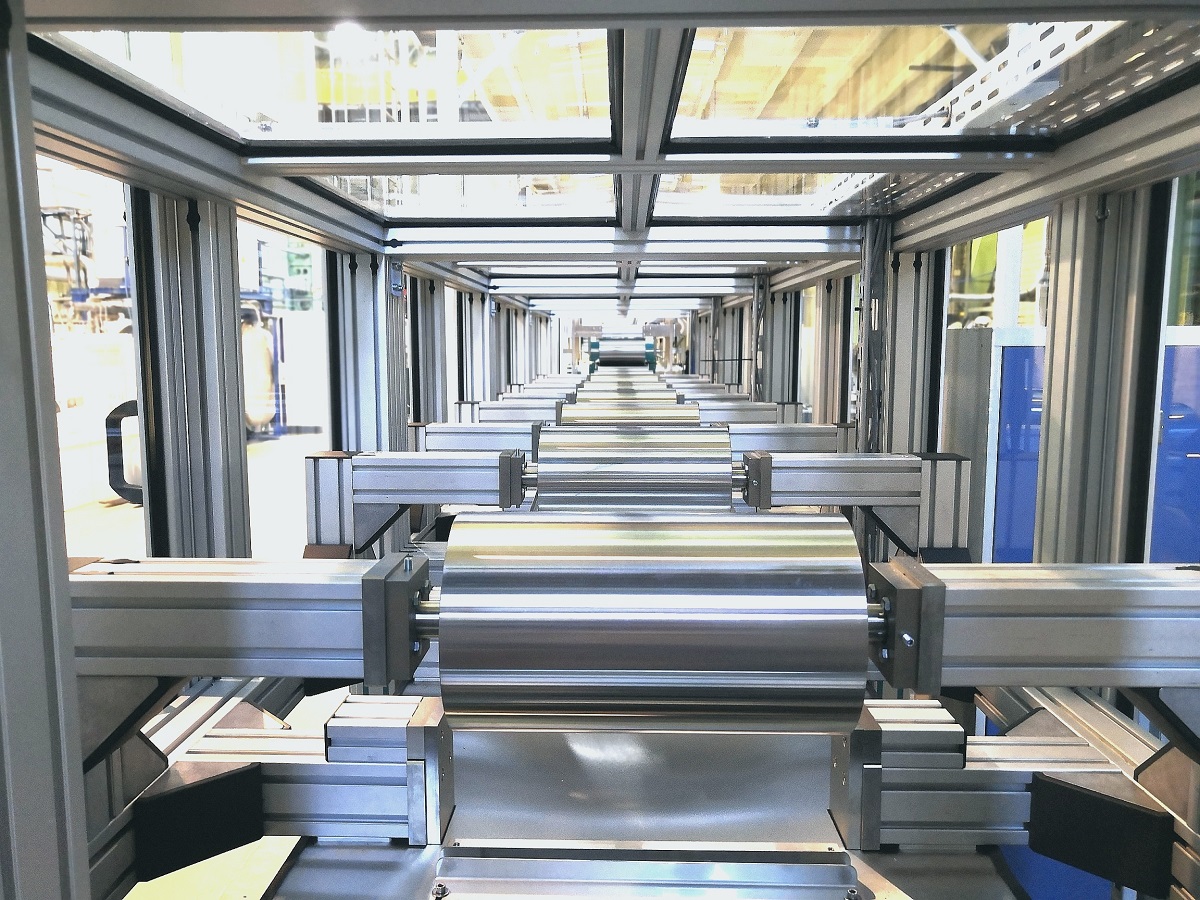

We are developing environmentally friendly and economically competitive processes for battery cell production and are researching new material concepts for high-performance and safe batteries. We also focus on the development of roll-to-roll processes for the cost-effective production of fuel cells. Here we offer innovative coating solutions for the mass production of metallic bipolar plates and use powerful laser sources for individual production steps such as cutting and joining.

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS